Gallery

About Project

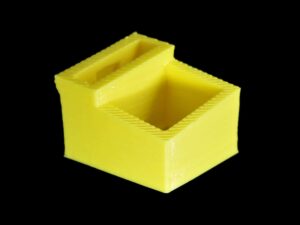

In the world of heavy-duty trucking, “overbuilt” is exactly what you want. This Solid Rubber Buffer is the final line of defense for a vehicleŌĆÖs suspension system. Unlike hollow springs that provide a softer progression, this solid component is engineered for maximum load-bearing capacity and extreme impact resistance.

The Role of a Solid Buffer

When a truck is fully loaded and hits a significant dip or obstacle, the suspension can travel to its absolute limit. This buffer sits between the axle and the chassis to:

- Prevent Metal-on-Metal Contact: It stops the axle from slamming into the frame, preventing costly structural cracks.

- Absorb Kinetic Energy: The high-density rubber compound dissipates massive amounts of force that would otherwise shatter less resilient materials.

- Maintain Stability: Under extreme weight, it provides a firm, reliable pivot point that keeps the vehicle level and controlled.

These are essential for dump trucks, mining vehicles, and tractors that operate in environments where “smooth roads” simply don’t exist.

Custom PU Manufacturing with FacFox

If your equipment demands even higher performance than standard rubber, FacFox is here to help. We specialize in Polyurethane (PU) manufacturing, providing a superior alternative for heavy-duty buffers and wear parts. Our custom PU casting offers significantly higher abrasion resistance and oil durability than traditional rubber, ensuring your components last longer in the harshest conditions. From rapid prototyping to high-volume production, FacFox delivers precision-molded PU solutions tailored to your specific industrial needs.

Solution

- Step 1: Material Preparation.┬ĀThe raw rubber compound was formulated and blended with specific reinforcing agents and stabilizers to ensure maximum impact resistance.

- Step 2: Molding Setup.┬ĀA high-strength steel compression mold was cleaned, inspected, and coated with a specialized release agent to facilitate the removal of the finished part.

- Step 3: Pre-forming.┬ĀThe unvulcanized rubber was weighed and shaped into a pre-form “slug” to ensure the mold cavity was filled precisely without excess waste.

- Step 4: Compression Molding.┬ĀThe rubber pre-form was placed into the heated mold cavity, and massive pressure was applied by a hydraulic press.

- Step 5: Vulcanization.┬ĀThe component was held under heat and pressure for a specific duration, during which the chemical cross-linking of the rubber molecules was completed.

- Step 6: Demolding.┬ĀOnce the curing cycle was finished, the solid buffer was ejected from the mold while still hot.

- Step 7: Deflashing.┬ĀExcess material, or “flash,” was trimmed away from the parting lines using precision cutting tools to achieve the final smooth finish.

- Step 8: Quality Inspection.┬ĀEach unit was subjected to a final visual check and hardness testing to verify compliance with industrial suspension standards.