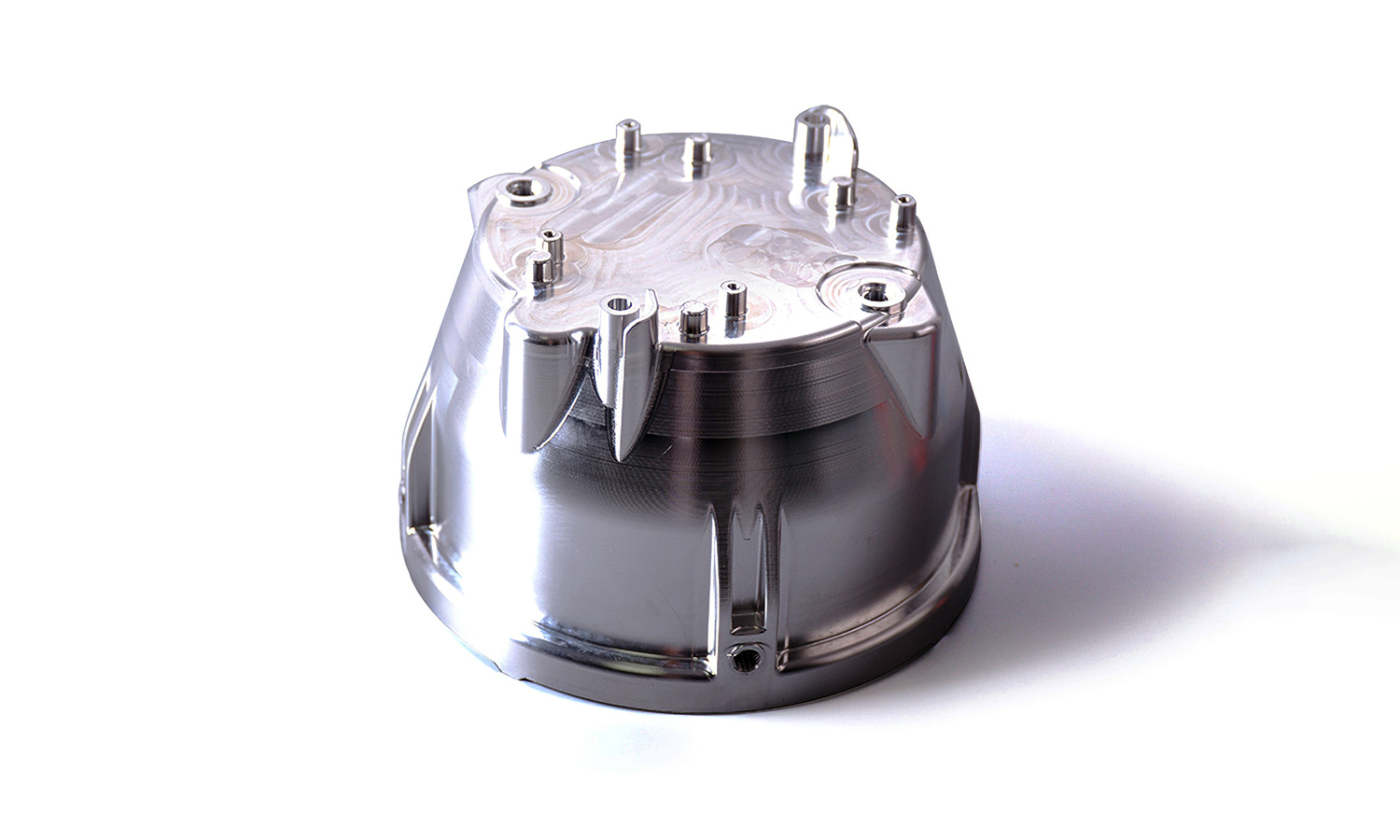

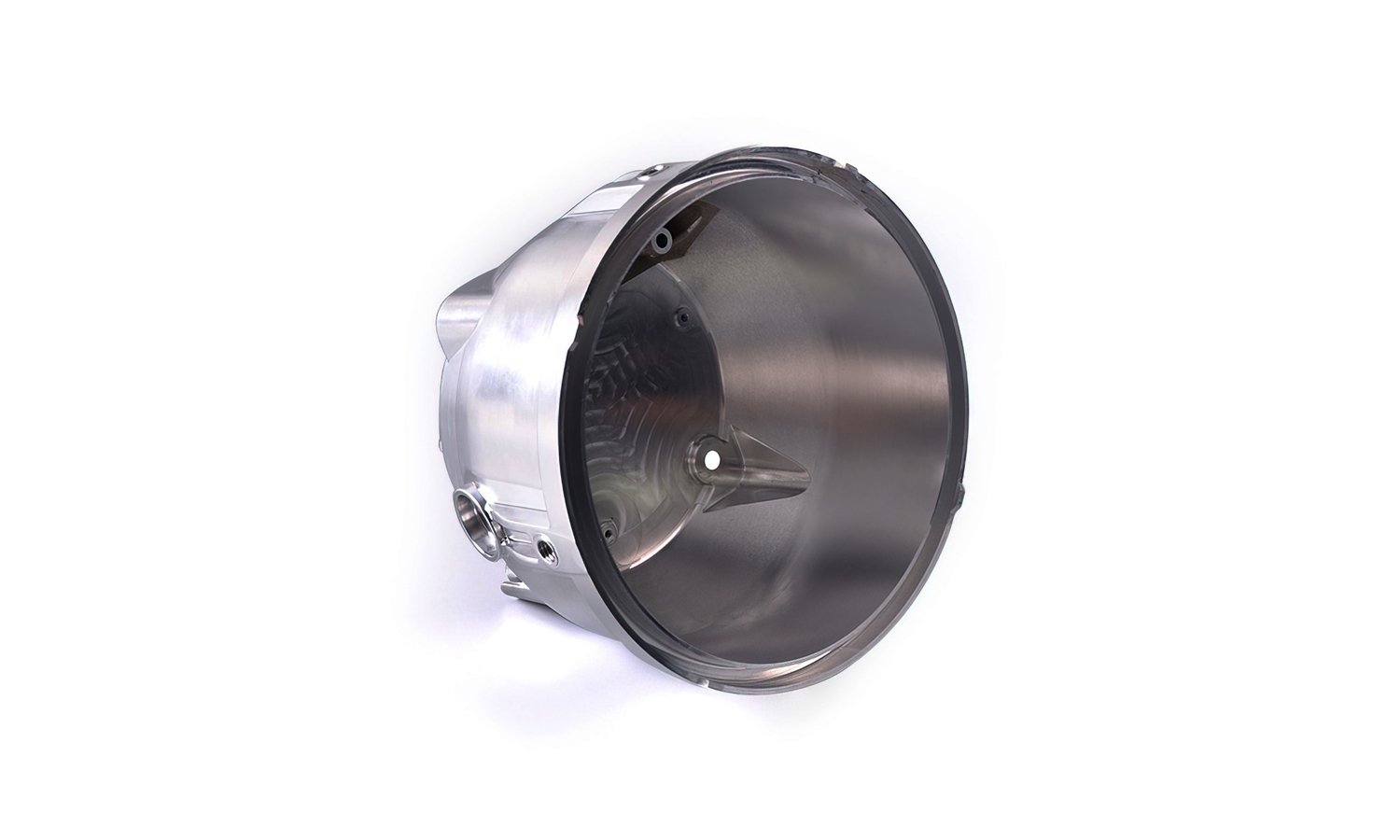

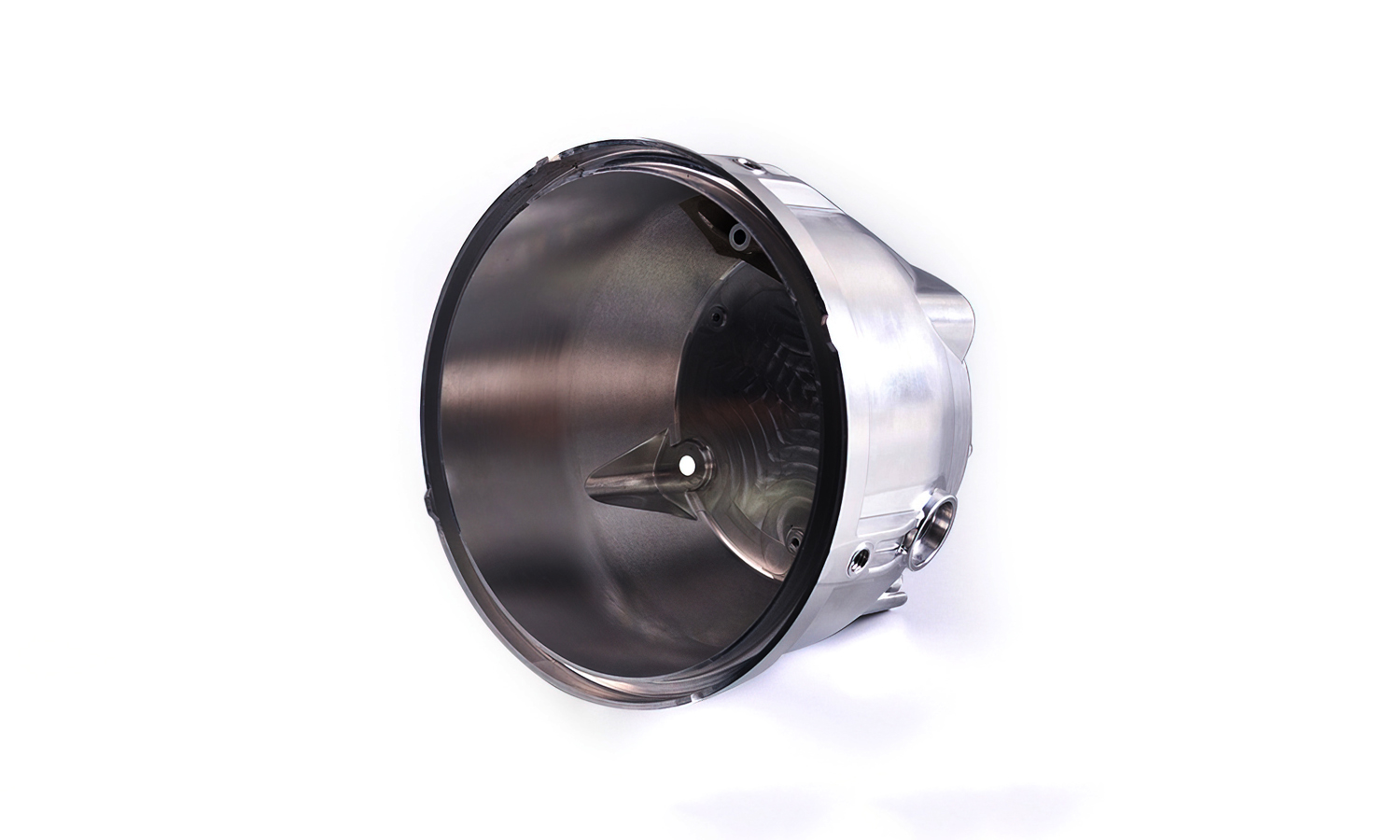

CNC Milled Aluminum Precision Component

- CNC Milled Stainless Steel Housing Tee Rail Assembly

- SLA 3D Printed Doll Made with Clear Resin and Tinted Orange Color

Posted on 2023-02-09 in Automotive ôñ ÌݧҧÎ

Gallery

About Project

CNC milling is still one of the most popular technologies for machining engineering metal parts.

CNC machining offers distinct benefits like pinpoint precision ã just a few micrometers on every axis ã which in turn has implications for achieving a superior surface finish without the need for supplementary processing.

When it comes to tolerances, CNC machining will also typically outperform 3D printing as a ãheat and reformã process isnãt required. Additionally, CNC machining is great for heavy-duty (literally heavy materials) end-use parts.

Solution

- Step 1: The CAD model was examined and transformed into a CNC-compatible format with the software AutoCAD.

- Step 2: A most suitable type of CNC machine was chosen according to the complexity of the product design and the cost of the workpiece.

- Step 3: Certain operations were configured and the G-codes were input on the machine. The workpiece was mounted on the machine as well.

- Step 4: The workpiece got shaped and the holes were drilled automatically. It would be inspected during and after the machining process for quality assurance.