- SLA 3D Printed White Resin Decorative Panel with Cut-outs

- [Holiday Notice] Labor Day vacation during May.1-5, shipping and customer service will pause

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 5 workdays

Gallery

About Project

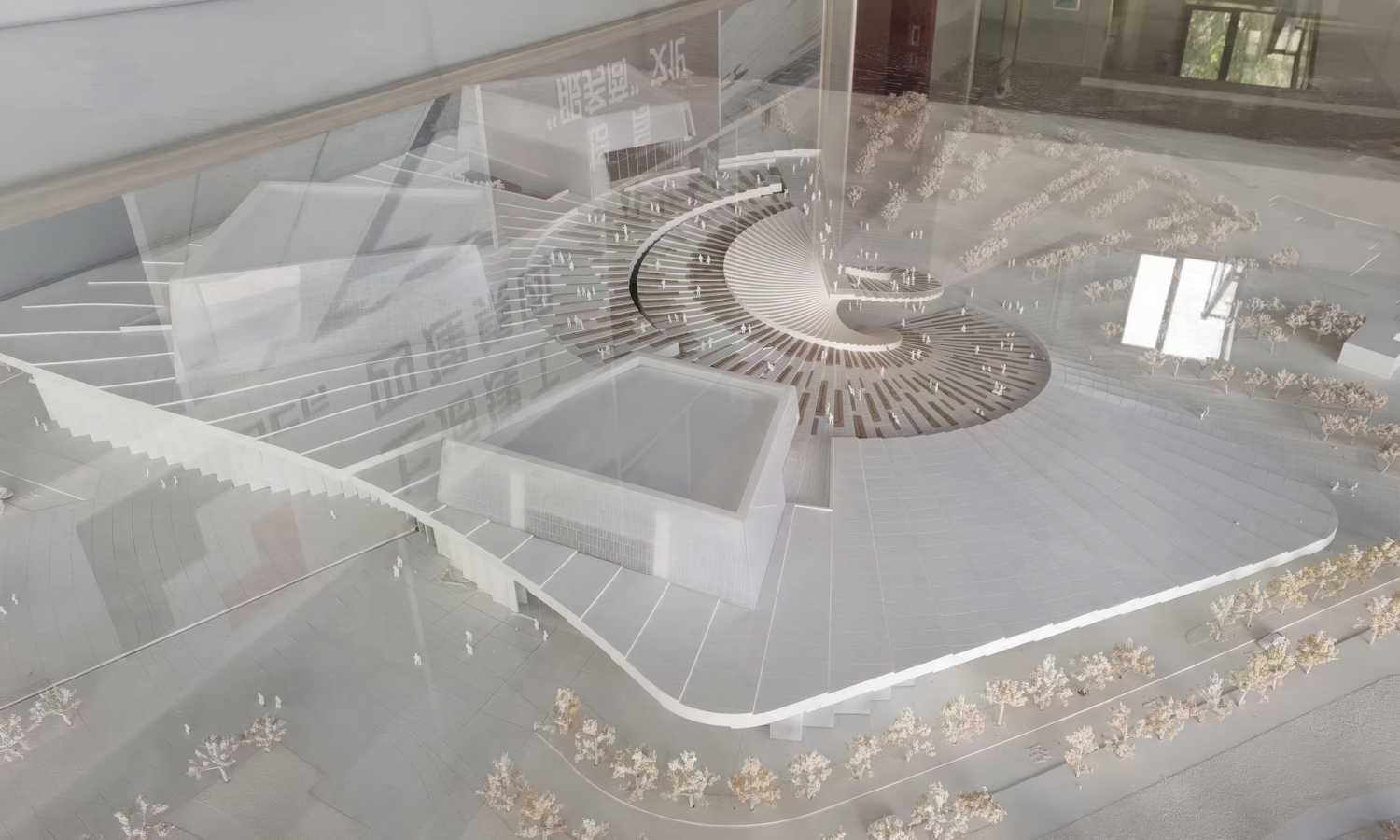

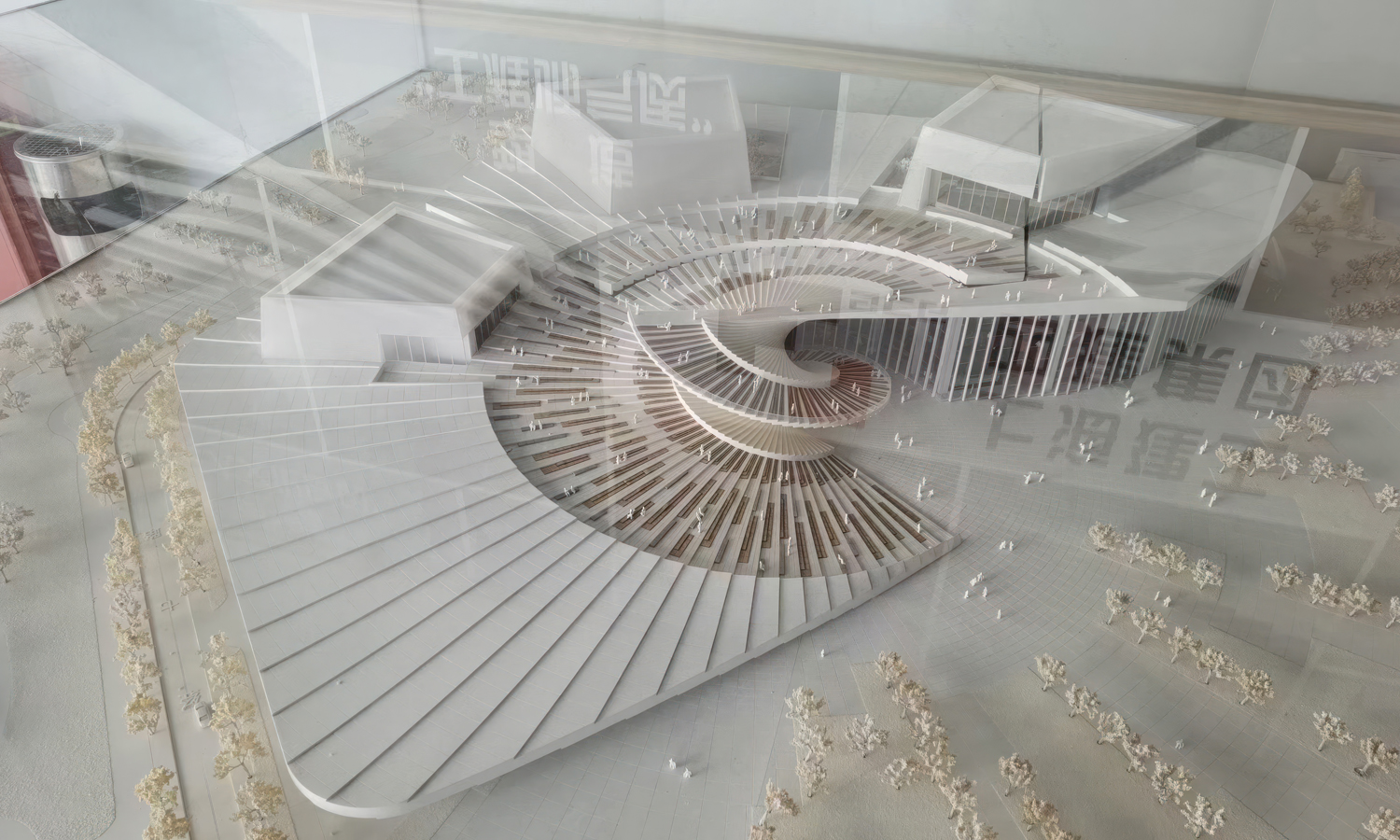

This stunning architectural model showcases the power of SLA 3D printing in bringing intricate designs to life. The model, created with SLA 3D printed resin, captures the essence of a modern opera house in Shanghai, boasting a distinctive spiral design.

The centerpiece of the model is the awe-inspiring spiral staircase, meticulously reproduced in white resin. The SLA printing process ensures exceptional detail, highlighting the intricate railings that wind their way upwards along the path. This unique design element, a staircase that leads upwards in a circular fashion, is the focal point of the opera house and the model perfectly captures its genius.

Beyond the remarkable spiral staircase, the model boasts a clean, white aesthetic that allows the overall design of the opera house to shine. Every detail, from the building's facade to subtle architectural flourishes, has been faithfully replicated using SLA 3D printing technology. The final product is a testament to the power of 3D printing in creating high-quality, detailed architectural models.

This stunning SLA 3D printed model is a perfect example of FacFox's commitment to providing architects with the most advanced 3D printing solutions. Our expertise in SLA 3D printing using resin allows us to create highly detailed and accurate models that perfectly capture even the most complex designs.

Whether you're working on a large-scale commercial project or a delicate residential renovation, FacFox can help you bring your vision to life. Contact us today to discuss your architectural 3D printing needs and experience the difference that SLA technology can make.

Solution

- Step 1: Design. Initially, the architectural design was created┬Āusing specialized software, ensuring all intricate details, including the distinctive spiral and railings, were accurately represented.

- Step 2: File Preparation. The digital model was then converted┬Āinto a format suitable for 3D printing. Support structures were┬Āadded┬Āto the design to ensure stability during the printing process.

- Step 3: Resin Selection. A resin suitable for capturing the high level of detail required for the opera house model was selected. SLA Durable Resin was also chosen┬Āfor its white color to match the design specifications.

- Step 4: Printing. The SLA 3D printer was prepared, and the resin tank was┬Āfilled┬Āwith the chosen material. The printing process was┬Āinitiated, with the model being┬Āconstructed┬Ālayer by layer. Ultraviolet light was┬Āused┬Āto cure the resin, solidifying each layer before the next one was┬Āapplied.

- Step 5: Cleaning. After printing, the model was removed┬Āfrom the printer and┬Āwashed┬Āto remove any uncured resin.

- Step 6: Post-Curing. The model was then exposed┬Āto additional ultraviolet light to ensure that the resin was fully cured and the material properties were┬Āoptimized.

- Step 7: Support Removal. Once post-curing was completed, the support structures were┬Ācarefully removed┬Āto reveal the detailed spiral staircase and railings.

- Step 8: Finishing. The model was sanded┬Āto remove any imperfections and to ensure a smooth surface finish. Any additional post-processing techniques were┬Āapplied┬Āto enhance the modelŌĆÖs appearance and to replicate the graceful design of the opera house.

- Step 9: Quality Check. The final step involved a thorough inspection where the model was examined┬Āfor accuracy and fidelity to the original design.