- PolyJet 3D Printed Full-color Resin White Power Ranger Miniature with Saba Sword

- SLA 3D Printed Resin Modern Wheelchair Scaled-down Prototype

Gallery

About Project

Are you looking for a way to showcase your architectural design in a realistic and impressive way? Do you want to create a durable and detailed model that can capture the attention of your clients and investors? If so, you might be interested in binder jet 3D printed sandstone architectural scale models from FacFox.

FacFox is a leading provider of 3D printing services for various industries, including architecture, engineering, construction, and design. They offer high-quality and affordable binder jet 3D printing solutions for creating stunning and accurate architectural scale models.

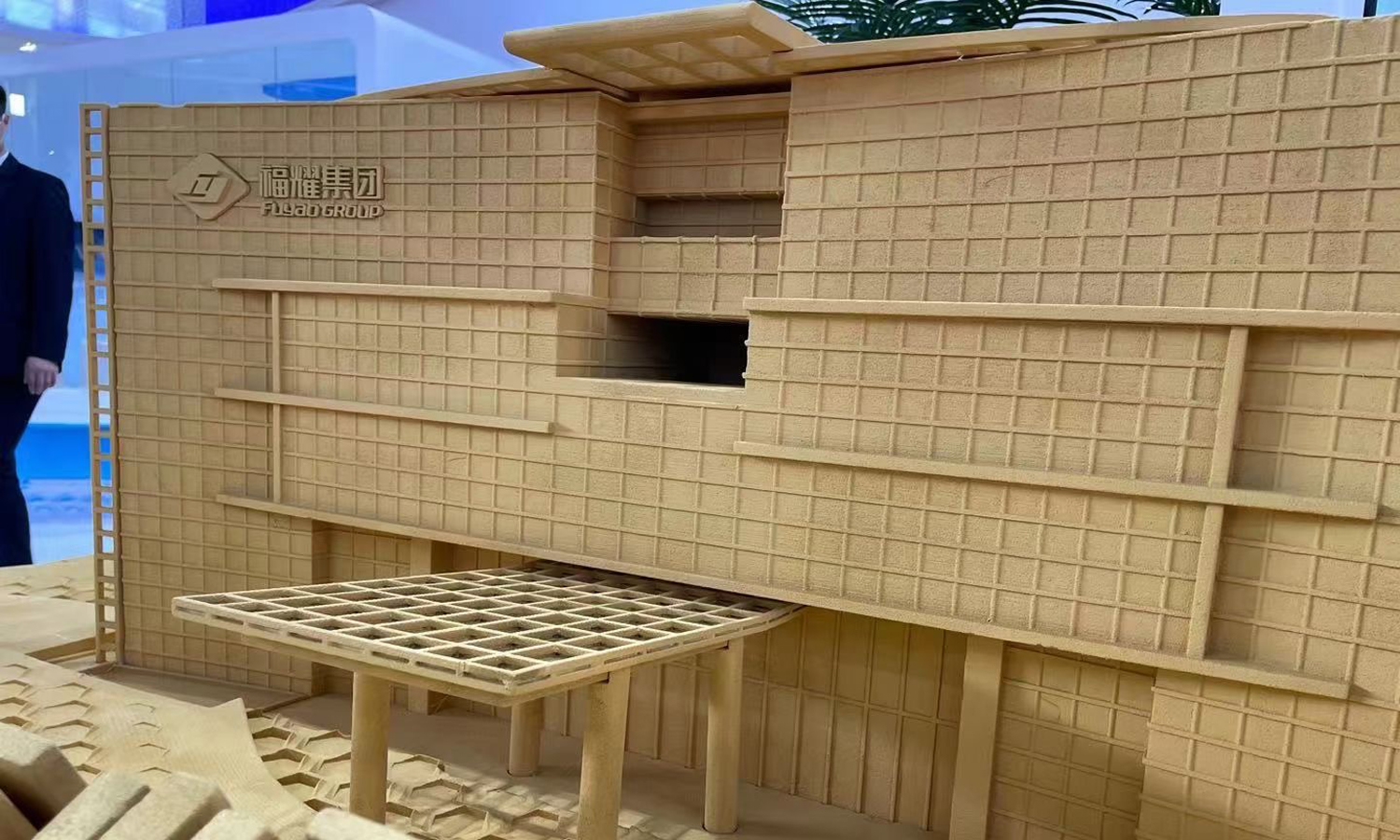

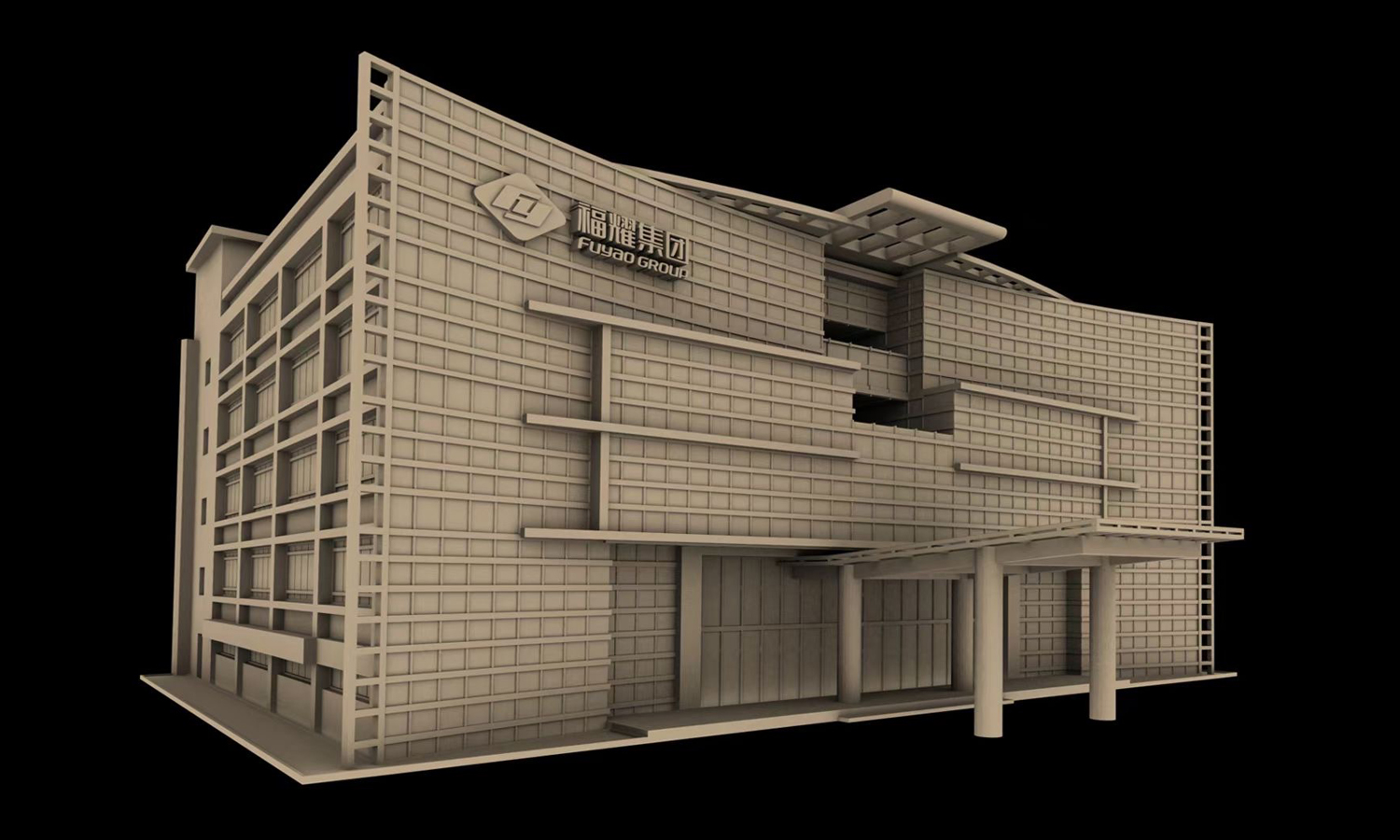

One of their early projects was a model of the Fuyao Group headquarters building in XiŌĆÖan, China. The Fuyao Group is a global leader in automotive glass manufacturing, and their headquarters building reflects their vision and values. The building features a remarkable antehall and rooftop, as well as a repeated square glass motif that matches the groupŌĆÖs main business. The model is very detailed, and it shows all of the features of the building, including the companyŌĆÖs logo, ŌĆ£ń”ÅĶĆĆķøåÕøó Fuyao GROUPŌĆØ, on the front.

The model was created using binder jet 3D printing technology, which uses a binder to bond layers of sandstone powder together. This process results in a full-color and textured model that resembles natural stone. Binder jet 3D printed sandstone models are also strong and durable, making them ideal for displaying and transporting.

If you are interested in ordering your own binder jet 3D printed sandstone architectural scale model from FacFox, you can visit their website or contact them via email. They will provide you with a free quote and a fast turnaround time. Whether you need a model for a presentation, exhibition, or portfolio, FacFox can help you create a stunning and realistic representation of your architectural design.

Solution

- Step 1: The 3D model of the building was created using CAD software and exported as an STL file.

- Step 2: The STL file was uploaded to the FacFox website and processed by their online platform. The platform automatically checked the model for errors, optimized it for printing, and calculated the price and delivery time.

- Step 3: The model was printed using a binder jet 3D printer at the FacFox facility. The printer used a print head to deposit a liquid binder onto a bed of sandstone powder, layer by layer. The binder bonded the powder particles together and formed the shape of the model. The printer also applied colored ink to the binder, creating a full-color and textured model.

- Step 4: After the printing was completed, the model was carefully removed from the powder bed and cleaned of any excess powder. The model was then cured in an oven to strengthen the binder and enhance the color.

- Step 5: The model was inspected for quality and packed for shipping. The model was wrapped in protective materials and placed in a sturdy box. The box was then labeled with the shipping information and sent to the customer.