Gallery

About Project

Hot pot or hotpot also known as soup-food or steamboat, is a Chinese cooking method, prepared with a simmering pot of soup stock at the dining table, containing a variety of East Asian foodstuffs and ingredients. Raw ingredients are pre-sliced into thin sections that will cook quickly and consistently in the simmering broth, which is maintained at a gentle boiling temperature. Most raw foods can be cooked in a hot pot, although they may have different cooking times, and must be immersed in the soup and then removed accordingly.

An architecture firm designed the factory for a hotpot manufacturer. The industry park was surrounded by trees, and left space for the parking lot in the front of its door. Behind the flower bed, there was a hotpot museum, which focused on and displayed traditional and modern hotpots.

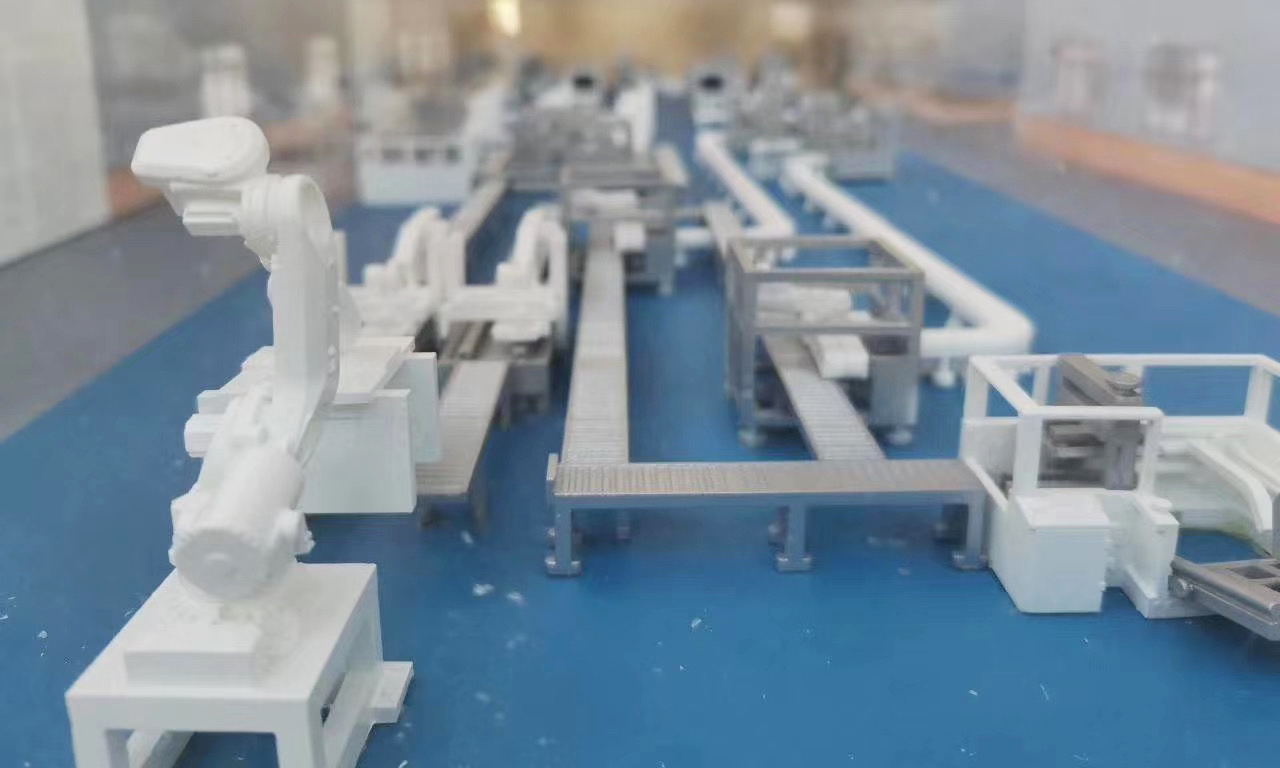

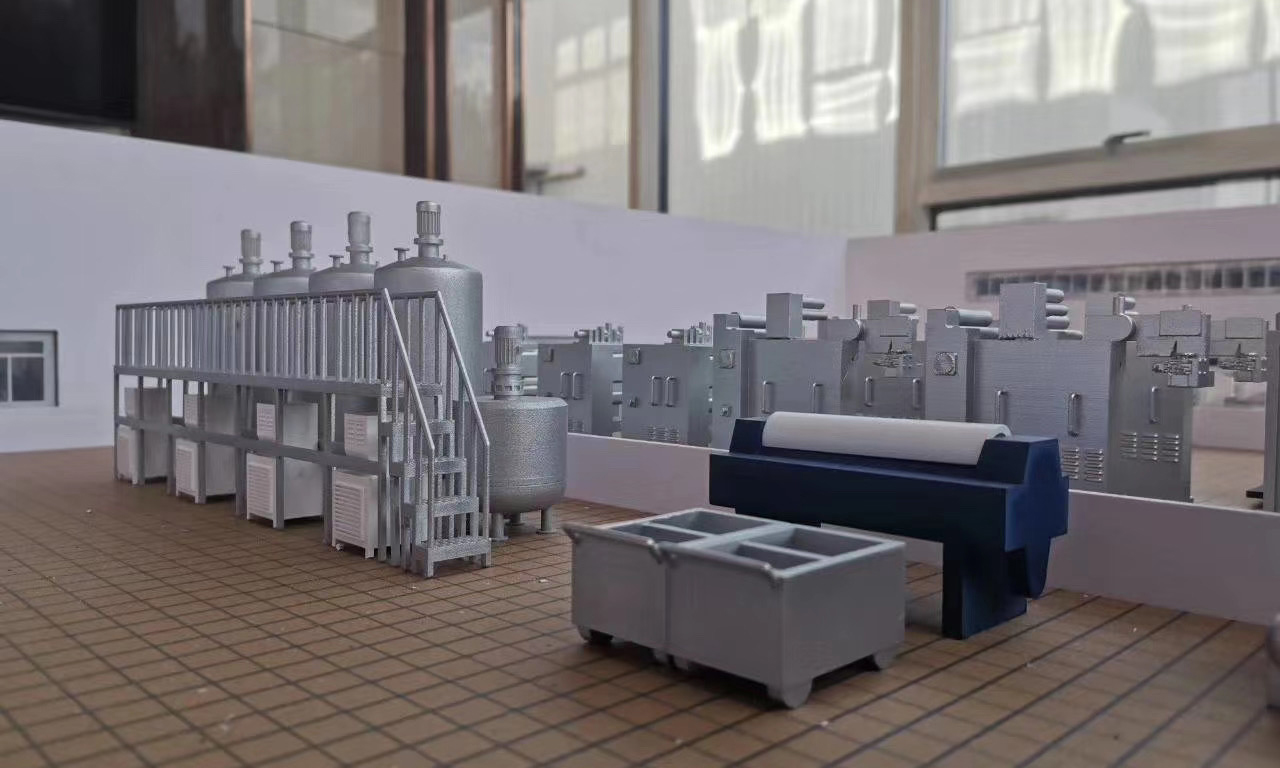

The assignment of the main plants was producing different kinds of hot pot soup base that can make a hot pot easier. They come in a variety of flavor which can enhance the hot pot that someone is making. The other plants were designed to make the auxiliary ingredients of hot pots.

All the plant models could be opened from the top and displayed all the equipment, shelves, conveyor belts on the production line. They are 3D printed through the help of SLA 3D printing technology.

Solution

- Step 1: Communicate with our client, list all the requirements of appearance and functions, recommend the best solution and negotiate about the price.

- Step 2: Examine and revise all the 3D models to make them printable.

- Step 3: 3D print all the models through SLA 3D printers. The car models are quite cheap on Alibaba, and the trees and grass are handmade though the traditional method. All the rest on the board are 3D printed with SLA ABS-like Resin.

- Step 4: Remove the supporting structure, post-cure the printed models in a chamber with UV.

- Step 5: Polish and paint all the parts, then assemble them.