- CNC Milled Die Steel Table Saw Zero Clearance Insert

- CNC Milled SS316L Pedal Extenders Spacers Adapters for Mountain Bikes

Gallery

About Project

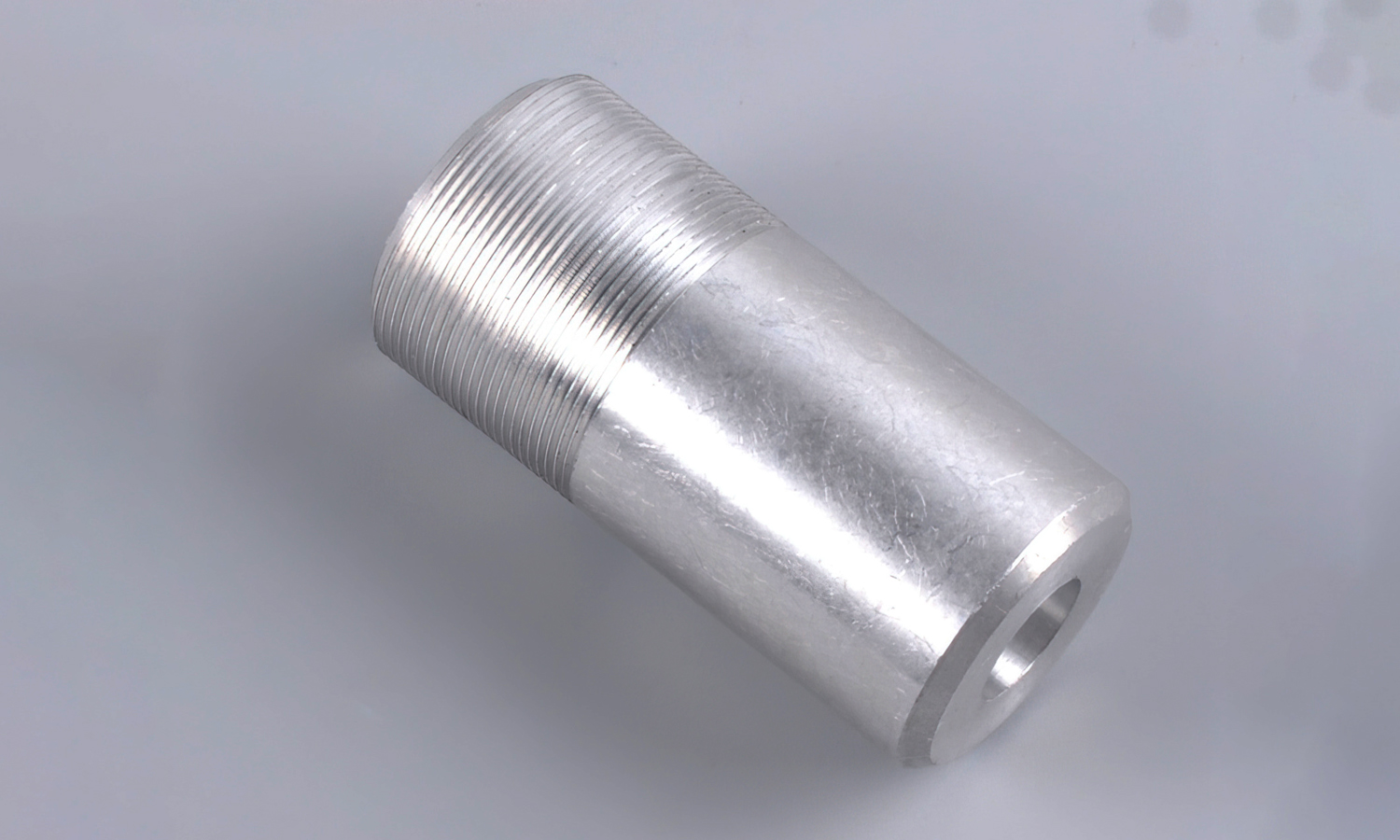

If you are looking for a high-quality and precise orifice extension for your piping system, you might want to consider a CNC-turned SS316L orifice extension with threading connection. This is a type of metal part that is used to adjust the flow rate of fluids or gases in pipes. It can also be used to connect different types of pipes or fittings.

The orifice extension is made of SS316L, which is a type of stainless steel that has excellent corrosion resistance, strength, and durability. It can withstand high temperatures and pressures, as well as harsh environments such as salt water, acids, and alkalis. SS316L is also easy to clean and maintain, making it ideal for sanitary applications.

It is manufactured by CNC turning, which is a process that uses computer-controlled machines to rotate and cut the metal into the desired shape and size. CNC turning ensures high accuracy, consistency, and quality of the orifice extension. It also allows for complex and intricate designs that are difficult to achieve by other methods.

The orifice extension has threading connections on both ends, which are standard pipe threads that can be easily screwed into different types of pipes. The threading connections provide a secure and leak-proof seal between the orifice extension and the pipes. They also allow for easy installation and removal of the orifice extension.

Visit FacFoxŌĆÖs website facfox.com today and get started on your custom CNC-turned SS316L orifice extension with a threading connection project! You will be amazed by their workmanship and service!

Solution

- Step 1: A cylindrical rod of SS316L stainless steel was selected as the raw material for the orifice extension. SS316L was chosen because of its excellent corrosion resistance, strength, and durability.

- Step 2: The rod was mounted on a CNC lathe, which was a computer-controlled machine that rotated and cut the metal into the desired shape and size. The CNC lathe was programmed with the design and specifications of the orifice extension, such as the diameter, length, hole size, and thread type.

- Step 3: The CNC lathe started to turn the rod at a high speed and used various cutting tools to remove excess material and create the orifice extension. The drills were used to make the hole in the center of the orifice extension. The taps and dies were used to create the threading connections on both ends of the orifice extension. The knurling tools were used to create a textured surface on the orifice extension for better grip and appearance.

- Step 4: The CNC lathe finished the turning process and produced the orifice extension. The orifice extension was then inspected for quality and accuracy using measuring instruments such as calipers, micrometers, and gauges. The orifice extension was also tested for functionality and performance by attaching it to a piping system and checking the flow rate of the fluid or gas passing through it.

- Step 5: The orifice extension was cleaned and polished to remove any burrs, chips, or marks left by the cutting tools. The orifice extension was then coated with a protective layer of oil or grease to prevent rusting and corrosion. The orifice extension was then packed and shipped to the customer.