- CNC Turned SS316L Orifice Extension with Threading Connection

- CNC Milled Aluminum Cylinder with Holes and Slot

Gallery

About Project

If you are a cyclist who needs more space between your feet and the pedals, you might be interested in pedal extenders. Pedal extenders are devices that attach to the pedals and increase the distance between the pedal axle and the crank arm. They can help improve your comfort, efficiency, and alignment while riding.

Pedal extenders are especially useful for riders who have large feet, wide hips, toe-out gait, or bow legs. They can also help prevent knee pain, foot numbness, or hip discomfort caused by improper foot positioning on the pedals.

There are different types of pedal extenders available on the market, but not all of them are created equal. Some are made of low-quality materials that can bend, break, or rust over time. Others are poorly designed and can interfere with the pedal mechanism or cause unwanted noise.

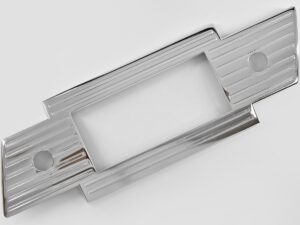

One of the best options for pedal extenders is CNC-milled SS316L pedal extenders. SS316L is a type of stainless steel that has high corrosion resistance, strength, and durability. It is also biocompatible, meaning it does not cause allergic reactions or inflammation in contact with human skin.

CNC milling is a process that uses computer-controlled machines to cut and shape metal parts with high precision and accuracy. CNC-milled pedal extenders have smooth edges, accurate dimensions, and consistent quality. They are also easy to install and remove with standard tools.

CNC-milled SS316L pedal extenders come in different lengths and widths to suit your needs and preferences. You can choose from 16mm or 20mm lengths, and 9/16″ or 1/2″ widths. They also come with washers to ensure a snug fit and prevent loosening.

If you are looking for a reliable and affordable source of CNC-milled SS316L pedal extenders, you should check out FacFoxБ─≥s CNC milling services. FacFox is a leading online platform that offers custom CNC machining for various industries and applications. You can upload your design, choose your material and specifications, and get an instant quote for your project. FacFox will then produce your parts with high-quality machines and materials, and deliver them to your doorstep in a timely manner.

FacFoxБ─≥s CNC milling services are not only limited to pedal extenders. You can also order other bike parts and accessories, such as chainrings, cassettes, stems, handlebars, seatposts, and more. FacFox can handle any size and complexity of your project, from prototypes to mass production.

Whether you need pedal extenders for mountain bikes, road bikes, recumbent bikes, or stationary bikes, FacFox can help you get them with CNC milling. Visit their website facfox.com today and see how they can turn your ideas into reality.

Solution

- Step 1: A 3D model of the pedal extender was designed using CAD software. The model specified the shape, size, and features of the part, as well as the location of the holes for the pedal axle and the crank arm.

- Step 2: The 3D model was converted into a set of instructions for the CNC machine, called G-code. The G-code defined the coordinates, movements, and speeds of the cutting tool, as well as the type and size of the tool.

- Step 3: A block of SS316L stainless steel was clamped onto the worktable of the CNC machine. The block was chosen to match the dimensions and thickness of the pedal extender.

- Step 4: The CNC machine started to cut and shape the metal block according to the G-code. The cutting tool moved along the X, Y, and Z axes, removing excess material and creating the desired contours and features of the part. The machine also drilled holes for the pedal axle and the crank arm at the appropriate positions.

- Step 5: The CNC machine finished machining the part and released it from the worktable. The part was then inspected for quality and accuracy, and cleaned to remove any burrs or chips. The part was also polished to give it a smooth and shiny surface. The part was then ready to be installed on the bike.