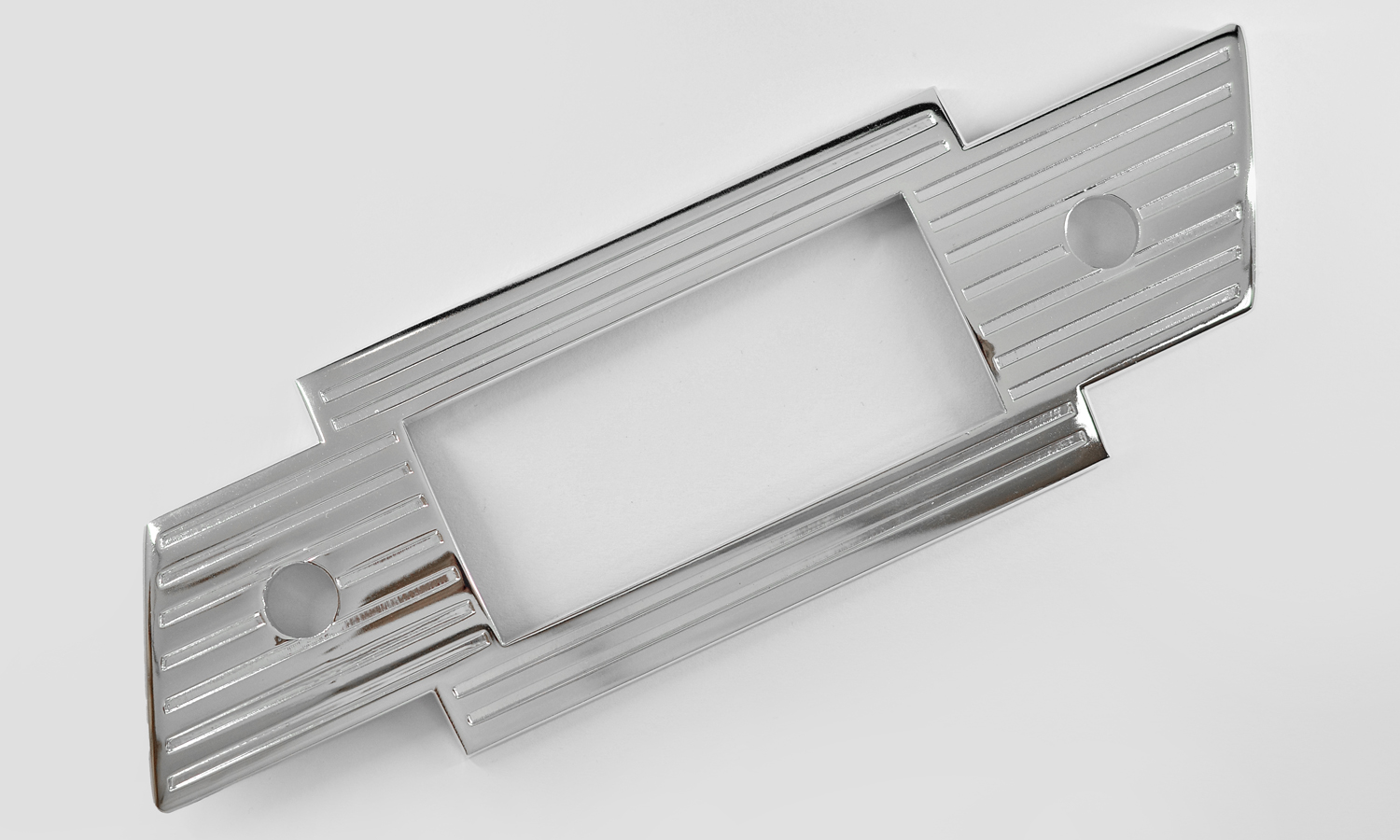

- SLA 3D Printed Silver Plated Resin Car Emblem Letter Plate

- SLA 3D Printed Neon Green Howling Wolf Resin Statue

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 4 workdays

Gallery

About Project

Here at FacFox, we're constantly innovating and pushing the boundaries of 3D printing technology. Today, we're excited to share a stunning example of our capabilities: a SLA 3D printed silver plated resin trim plate prototype designed for the automotive industry.

This seemingly simple part, with its sleek silver finish and intricate details, showcases the remarkable potential of 3D printing for automotive applications. While it may appear to be a traditional metal plate, it's actually crafted from high-quality resin using our cutting-edge SLA printing technology. This allows for unparalleled design freedom and complex geometries, impossible to achieve with traditional manufacturing methods.

Key Features

- Material: SLA 3D printed resin, plated with silver for a premium aesthetic

- Design: Decorative trim plate with a large cutout and two drilled holes

- Finish: Beautiful silver finish on the front face, highlighting the intricate details

- Benefits: Lightweight, customizable, and cost-effective compared to traditional metal parts

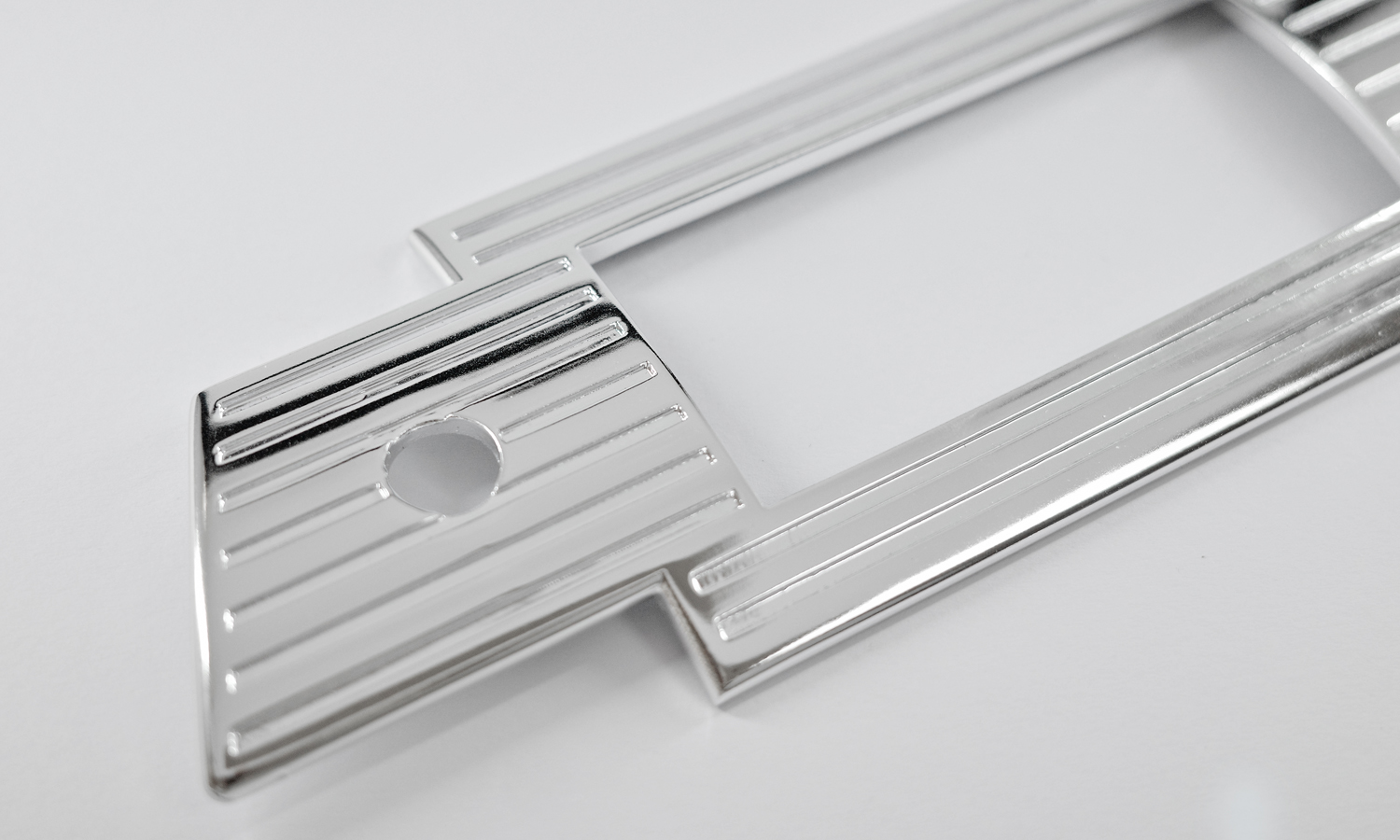

While the overall finish is impressive, a closer look reveals subtle lines within the grooves, hinting at the resin base beneath the plating. This is a testament to the current limitations of plating on 3D-printed parts. However, it also highlights the rapid advancements in this technology. At FacFox, we're actively working to overcome these challenges and deliver flawless silver finishes on even the most intricate 3D-printed parts.

Why Choose FacFox for Your Automotive Prototyping Needs?

- Cutting-edge technology: We offer a wide range of 3D printing technologies, including SLA, SLS, and FDM, to suit your specific needs.

- Expert design and engineering support: Our team of experienced professionals can help you optimize your designs for 3D printing and ensure successful prototyping.

- Fast turnaround times: We understand the importance of speed in the automotive industry, and we're committed to delivering prototypes quickly and efficiently.

- Unmatched quality: We use only the highest quality materials and processes to ensure your prototypes meet the strictest standards.

Ready to push the boundaries of what's possible with 3D printing in the automotive industry? Contact FacFox today to discuss your project and see how our expertise can help you bring your vision to life.

Solution

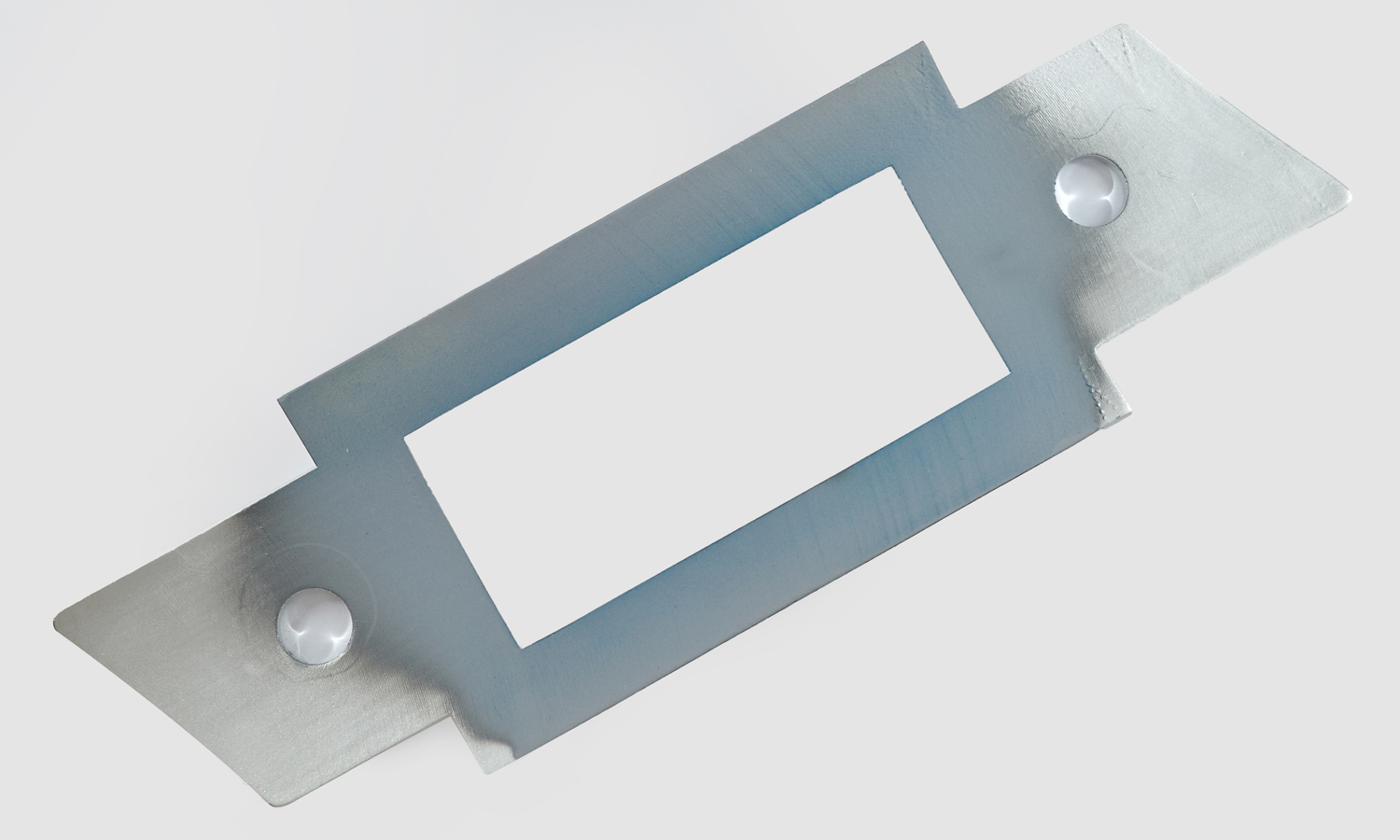

- Step 1: The prototypeŌĆÖs design was finalized using advanced CAD software, ensuring that the specifications for the decorative metal plate appearance were met, including the central dash cut-out and side holes.

- Step 2: The resin trim plate was then produced using SLA 3D printing technology. A high-precision laser was employed to solidify SLA ABS-like Resin layer by layer, forming the intricate details of the plate.

- Step 3: After printing, the prototype was subjected to thorough post-processing. Excess resin was removed, and the plate was sanded to smooth out any irregularities on the surface.

- Step 4: Subsequently, the resin plate was plated. A silver coating was meticulously applied. The front face of the plate received a final coating, bestowing it with a beautiful silver finish that accentuated its decorative appeal.

- Step 5: The finished product was closely inspected. It was noted that, while the silver plating granted a stunning visual effect, imperfections such as small lines within the grooves were present, indicative of the complex nature of the manufacturing process.