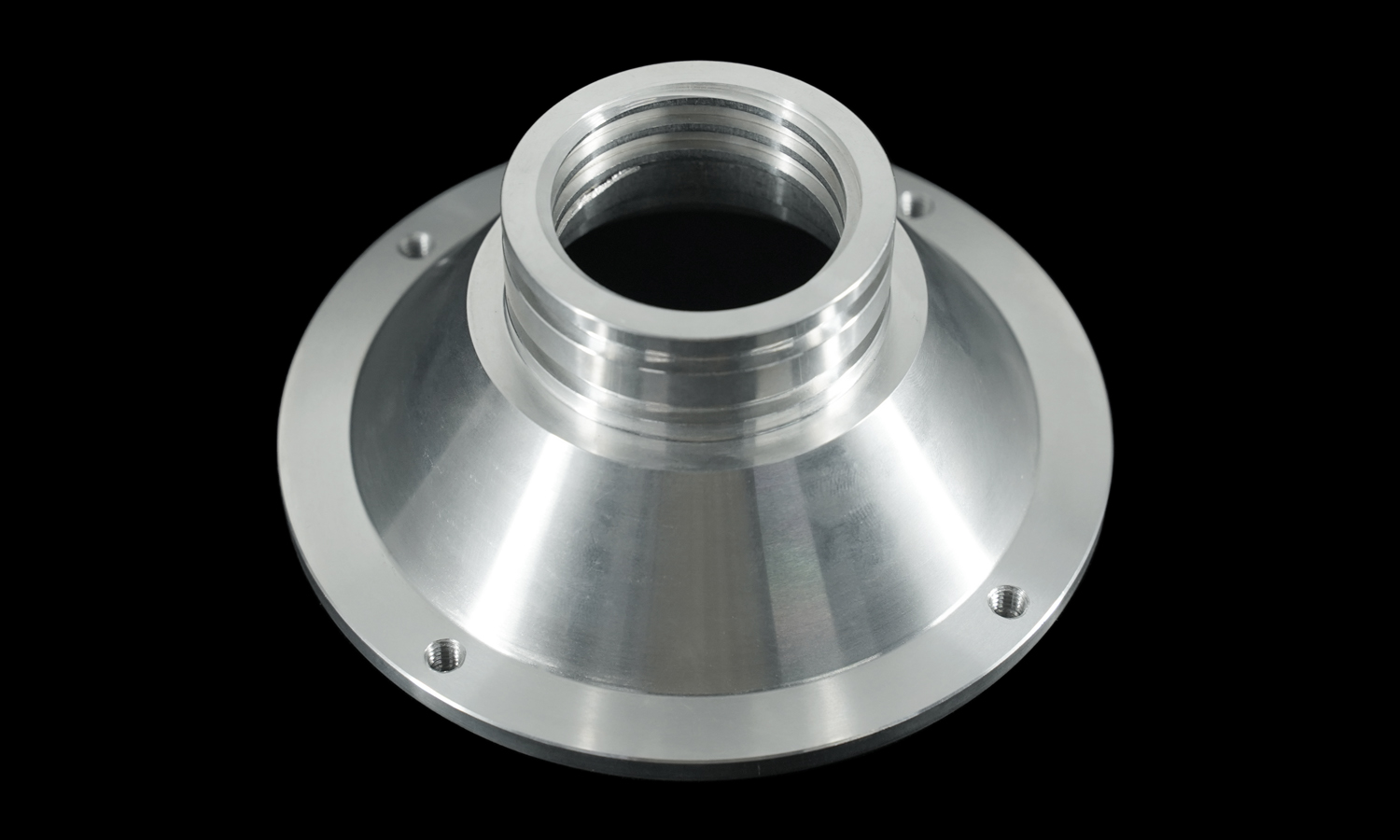

- CNC Milled Aluminum 6061 Billet Engine Post Mount Automotive Accessories

- CNC Milled Aluminum 6061 Billet Panel with Concave Oval Patterns

Gallery

About Project

Are you looking for a robust and reliable bracket for your vehicle? If so, you might want to check out the CNC Milled Aluminum 6061 Round Table Plate Base. These are circular plates with holes that can be used to mount various components in your vehicle, such as engine mounts, exhaust systems, or suspension parts.

The brackets are made of aluminum 6061, which is the most popular aluminum alloy for CNC milling. It has a good strength-to-weight ratio, low cost, recyclability, non-magnetic, heat treatable, and natural corrosion resistance.

The brackets are machined by FacFox, a leading CNC milling service for the automotive industry. FacFox has state-of-the-art CNC machines that can mill aluminum parts with high precision and efficiency. FacFox can also customize the brackets according to your specifications, such as diameter, thickness, hole size, and finish.

If you want to custom a CNC Milled Aluminum 6061 Round Table Plate Base, you can visit FacFoxБ─≥s website and get an instant quote. You can also see some of their previous projects and testimonials from satisfied customers. FacFox guarantees fast delivery, competitive prices, and excellent customer service.

Solution

- Step 1: The CAD model was examined and transformed into a CNC-compatible format with the software AutoCAD.

- Step 2: A most suitable type of CNC machine was chosen according to the complexity of the product design and the cost of the workpiece.

- Step 3: Certain operations were configured and the G-codes were input on the machine. The workpiece was mounted on the machine as well.

- Step 4: The workpiece got shaped and the threads were drilled automatically. It would be inspected during and after the machining process for quality assurance.