- CNC Milled Glass Truncated Cone Sample with Transparent and Frosted Satin Surface

- CNC Turned 45 Steel Seamless Ring Heavy Gauge with Default Finishing

Gallery

About Project

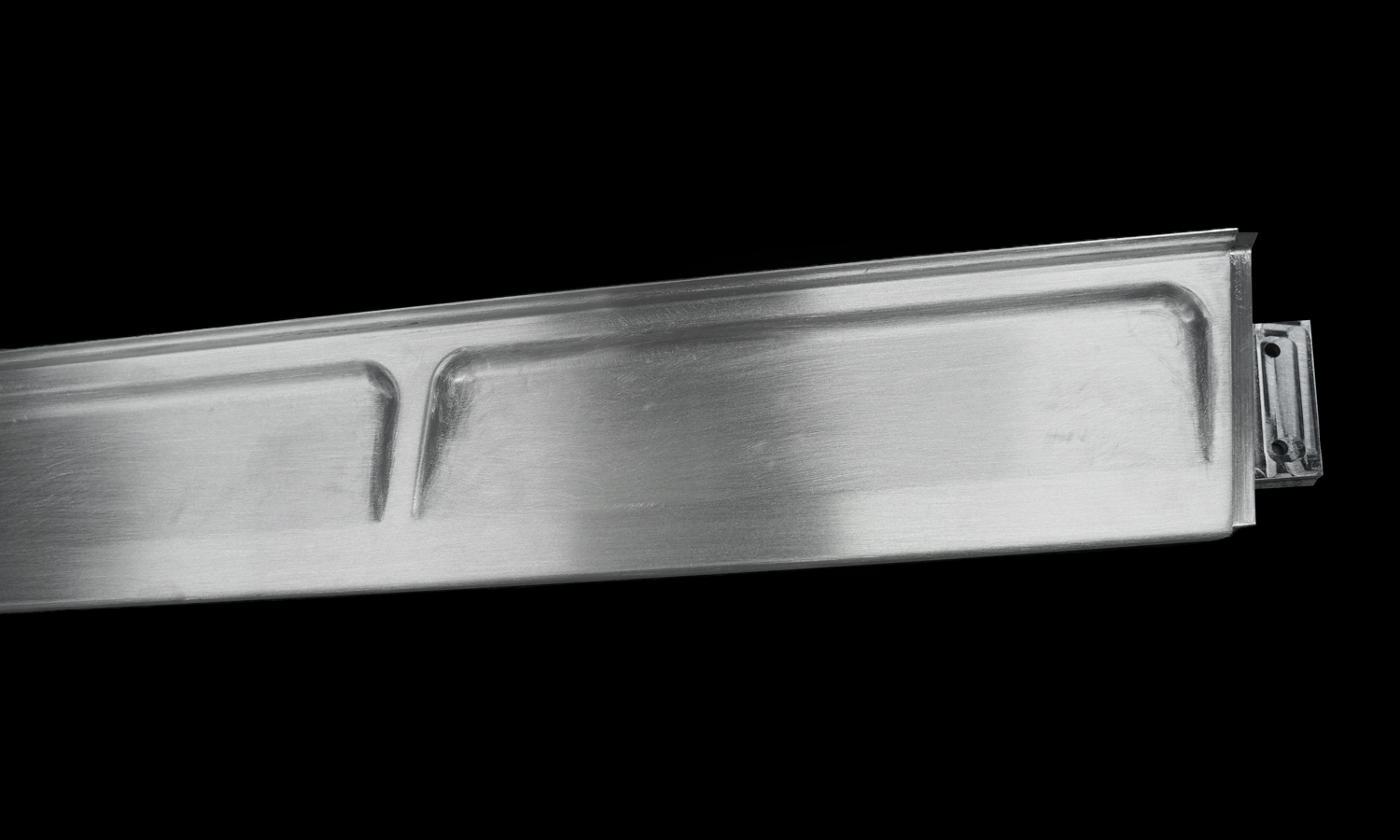

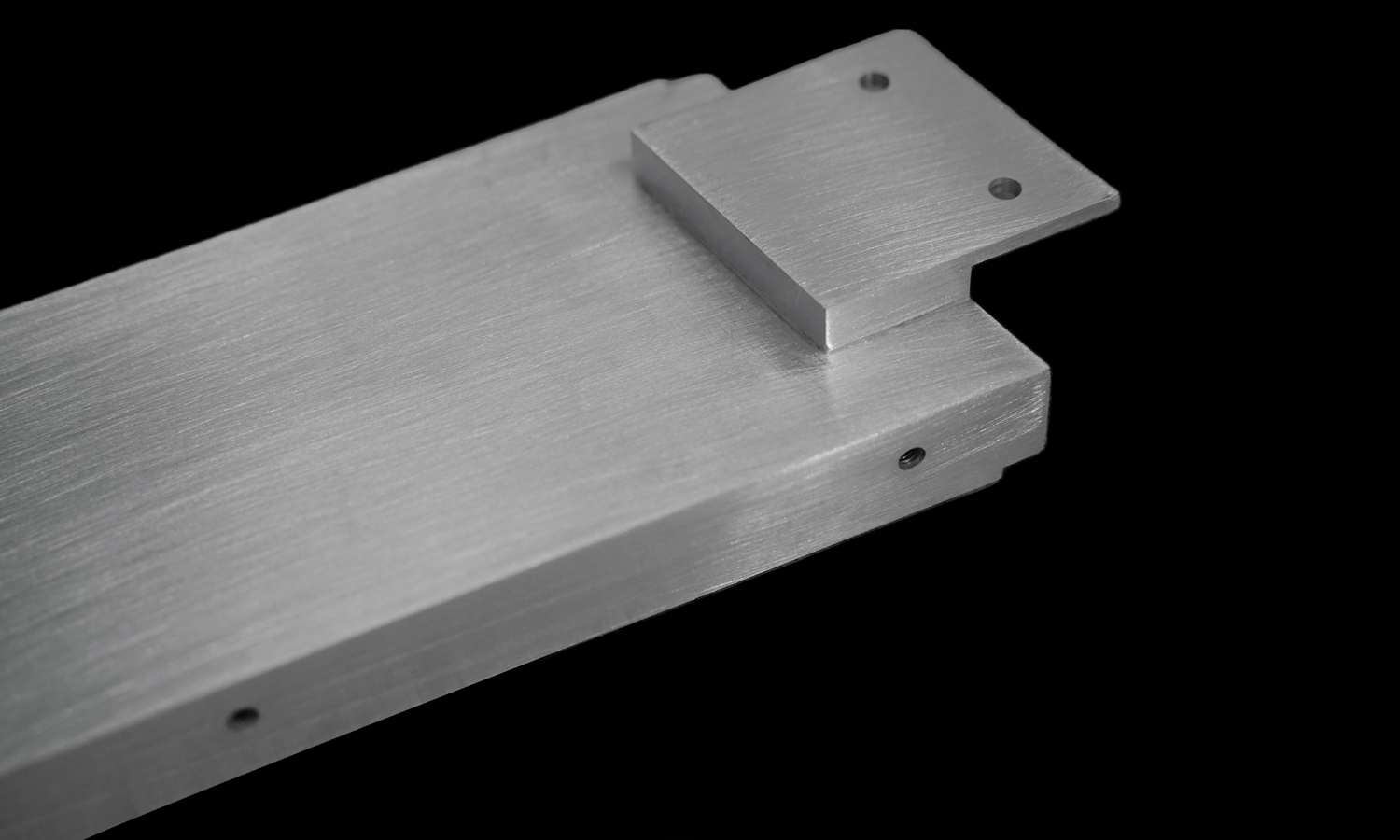

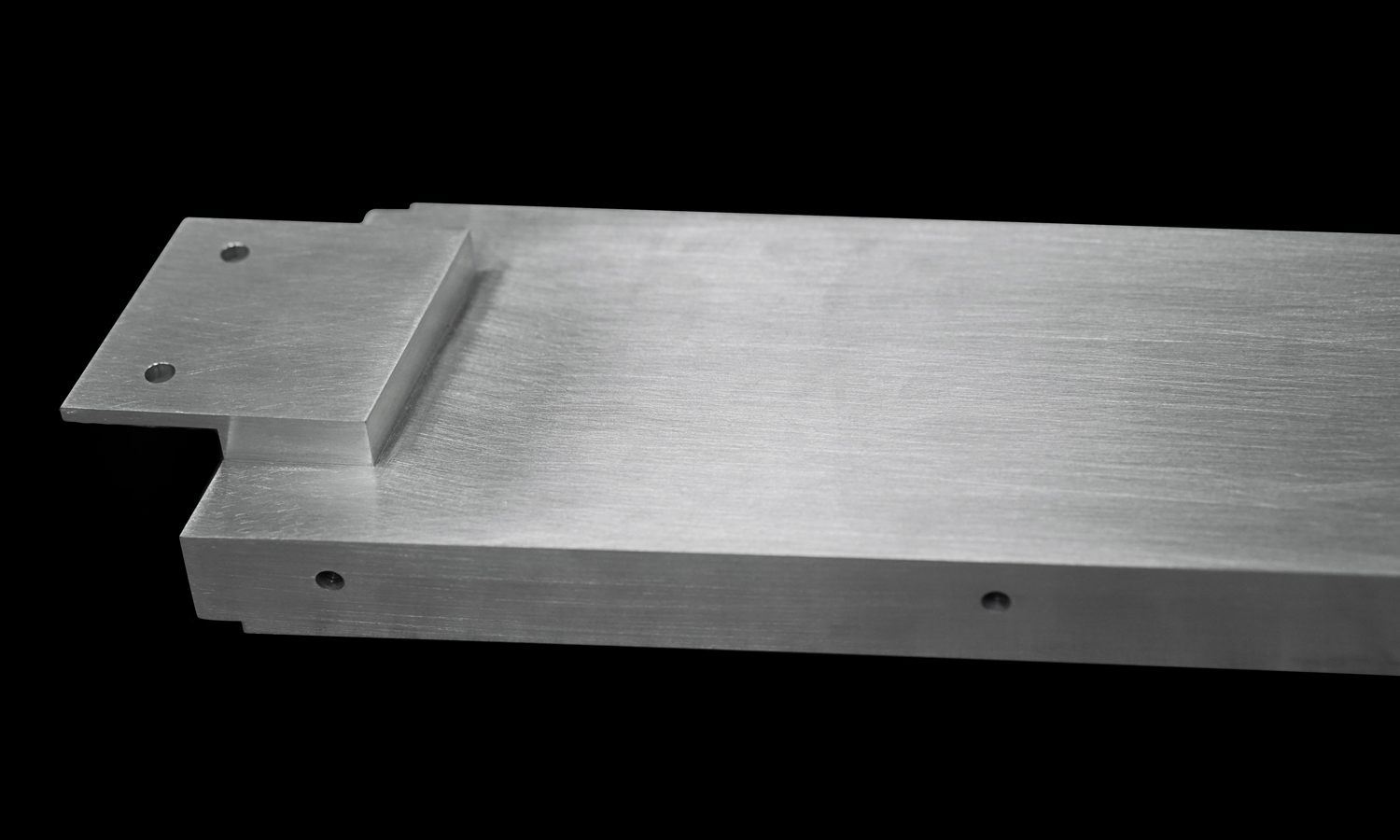

A bumper impact bar, or a reinforcement cross member rear, is a part that connects the two bumper impact bars at the rear of a vehicle. It provides structural support and stability to the bumper assembly and helps absorb the impact force in case of a collision.

One of the advantages of using CNC milling to produce this part is that it allows for high precision and customization. CNC milling can create complex shapes and features with tight tolerances and smooth finishes. CNC milling can also produce parts faster and more efficiently than other methods, such as casting or welding.

Aluminum 6061 is a popular aluminum alloy that has excellent mechanical properties and machinability. It has a good strength-to-weight ratio, low cost, recyclability, non-magnetic, heat treatable, and natural corrosion resistance. Aluminum 6061 can also have different heat treatments, such as T6, which increases its hardness and strength.

A CNC milled AL6061 bumper impact bar can offer several benefits for the automotive industry. First, it can reduce the weight and fuel consumption of the vehicle, as aluminum 6061 is lighter than steel. Second, it can improve the safety and performance of the vehicle, as aluminum 6061 can absorb more energy and resist deformation better than steel. Third, it can enhance the aesthetics and durability of the vehicle, as aluminum 6061 can have a polished surface and resist rust and corrosion.

If you are looking for a reliable and professional CNC milling service provider for your aluminum 6061 bumper impact bar project, you should consider FacFox. FacFox is a leading online platform that offers high-quality CNC machining services for various industries and applications.

FacFox has a network of experienced and certified CNC machinists who can handle any design and specification you need. FacFox also has a fast turnaround time and competitive pricing for your CNC milling project. Whether you need one piece or thousands of pieces, FacFox can deliver your CNC milled aluminum 6061 bumper impact bar reinforcement cross member rear with accuracy and efficiency.

To learn more about FacFoxŌĆÖs CNC milling services and get an instant quote for your project, visit their website at https://www.facfox.com/cnc-machining/.

Solution

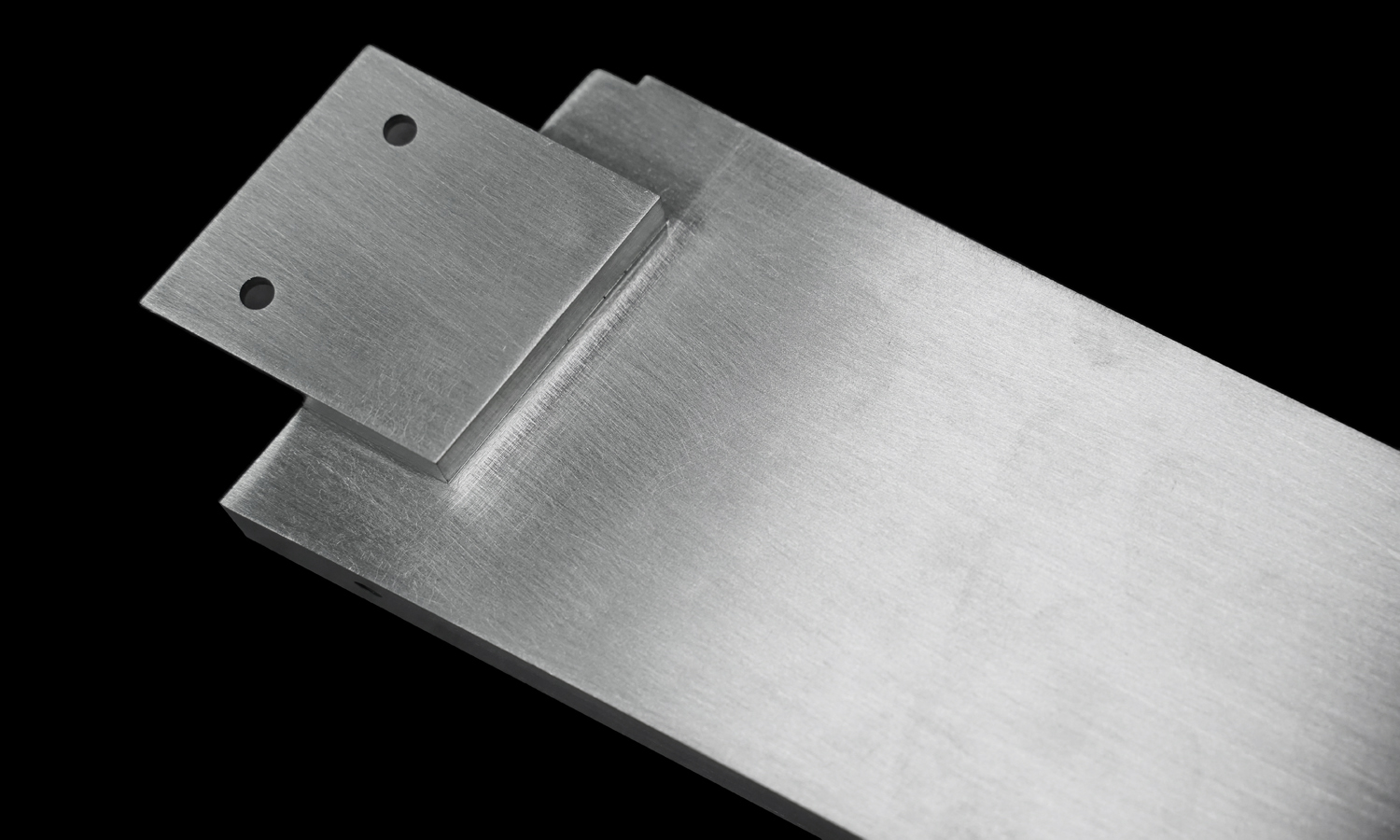

- Step 1: The CAD model was examined and transformed into a CNC-compatible format with the software AutoCAD.

- Step 2: A most suitable type of CNC machine was chosen according to the complexity of the product design and the cost of the workpiece.

- Step 3: Certain operations were configured and the G-codes were input on the machine. The workpiece was mounted on the machine as well.

- Step 4: The workpiece got shaped and the holes were threaded automatically. It would be inspected during and after the machining process for quality assurance.