- Open Cast Molded Polyurethane Spider for Jaw Couplings

- CNC Milled Aluminum 6061 Bumper Impact Bar Reinforcement Cross Member Rear

Gallery

About Project

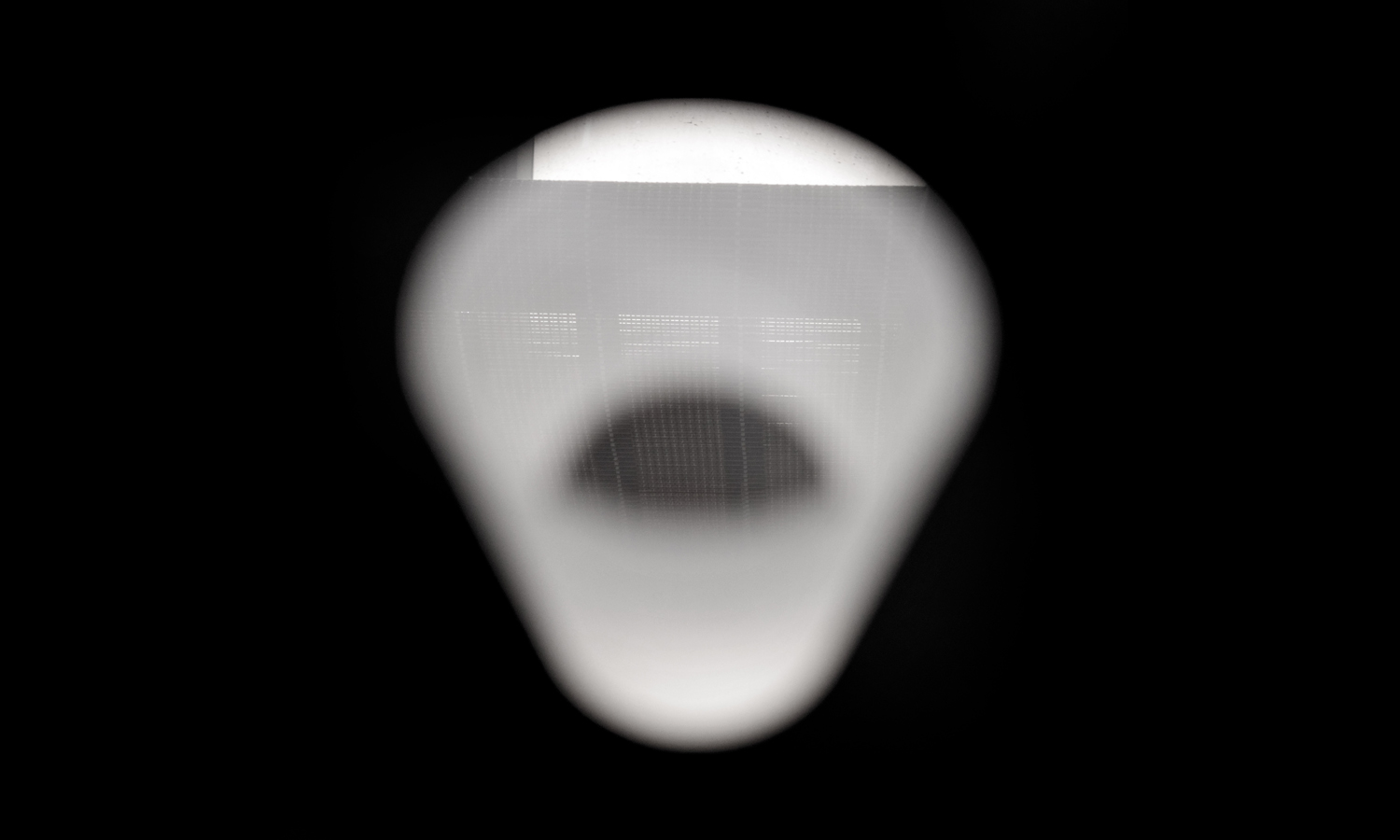

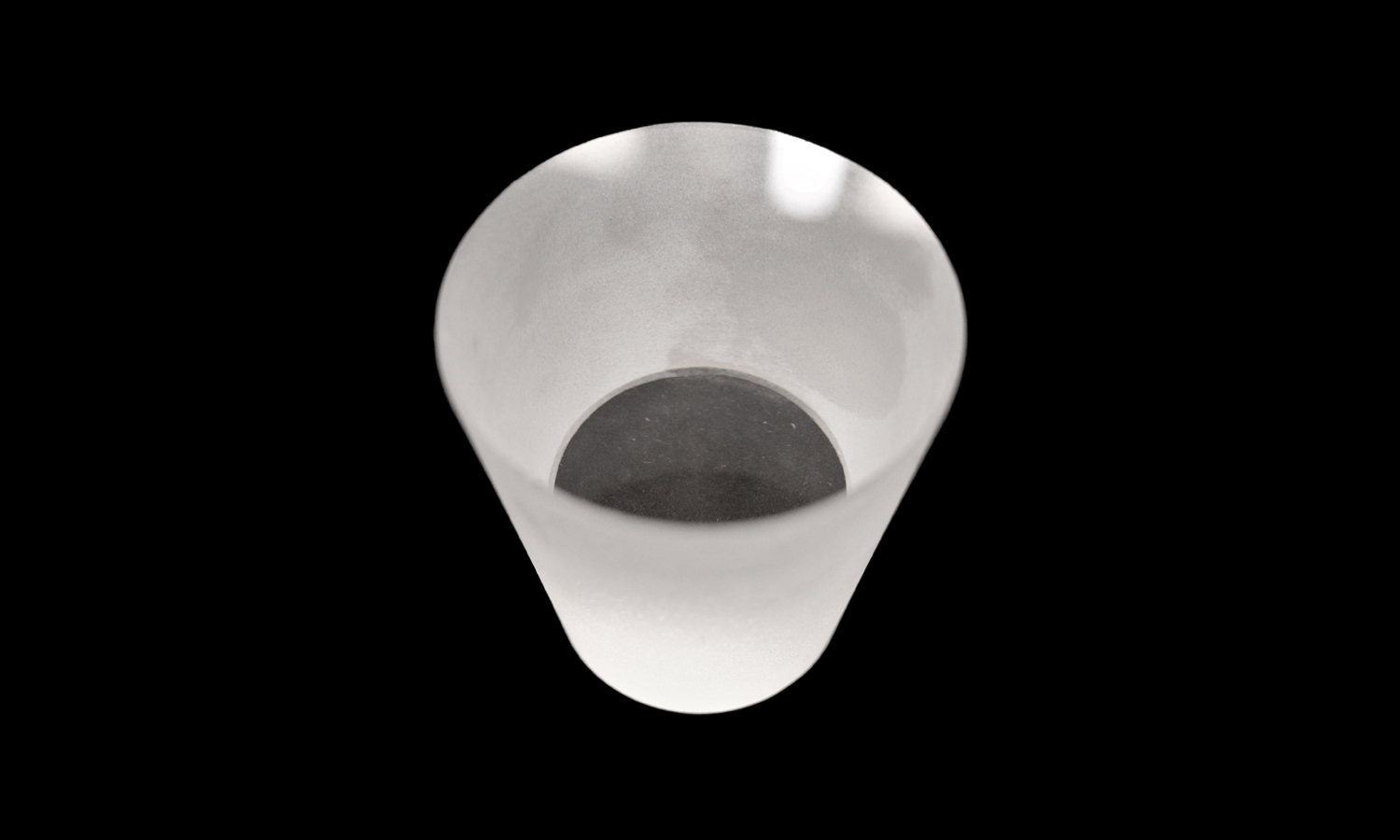

This sample is a glass truncated cone with a clear top and bottom face and a frosted satin side face. It is made of high-quality glass material that is durable and resistant to scratches and cracks. The sample is about 3 cm high and has a smooth and even surface.

The sample was created using CNC milling, a process that uses computer-controlled machines to cut and shape glass with high precision and flexibility. CNC milling can create complex geometries and features that are not possible with conventional methods. CNC milling can also handle a wide range of materials, including quartz, borosilicate, fused silica, and more.

If you are looking for a reliable and professional CNC milling service for your glass projects, look no further than FacFox. FacFox is a leading online platform that offers high-quality CNC milling services for various materials, including glass, metal, plastic, wood, and more.

FacFox has state-of-the-art CNC machines that can handle any design and specification you have in mind. Whether you need simple shapes or complex features, FacFox can deliver them with fast turnaround time and competitive prices.

FacFox also has a team of experienced engineers and technicians who can assist you with your design and production needs. They can help you choose the best material, tool, and process for your project and ensure that your final product meets your expectations.

FacFox is your one-stop shop for all your CNC milling needs. Contact us today to get a free quote and start your project with us.

Solution

- Step 1: To make the sample, a glass blank was mounted on a CNC machine and a diamond tool was used to cut the top and bottom faces of the cone. The diamond tool was programmed to follow a G-code that specified the dimensions and angles of the cone. The top and bottom faces were cut with high speed and low feed to ensure a smooth and clear finish.

- Step 2: Next, the side face of the cone was milled using a different diamond tool that created a frosted satin effect. The tool was programmed to move along the side face with low speed and high feed to create tiny grooves and scratches on the surface. The frosted satin effect gives the side face a rough but even texture that diffuses light and creates a soft glow.

- Step 3: The sample was then cleaned and inspected for any defects or imperfections. The result is a beautiful glass truncated cone that showcases the versatility and accuracy of CNC milling.