- Independence Day sales is coming soon…We added a giant FDM ABS 3D printer!

- CNC Milled Glass Truncated Cone Sample with Transparent and Frosted Satin Surface

Material Other

Quantity 100 pcs

Price Range $100-1,000

Lead Time 7 workdays

Gallery

About Project

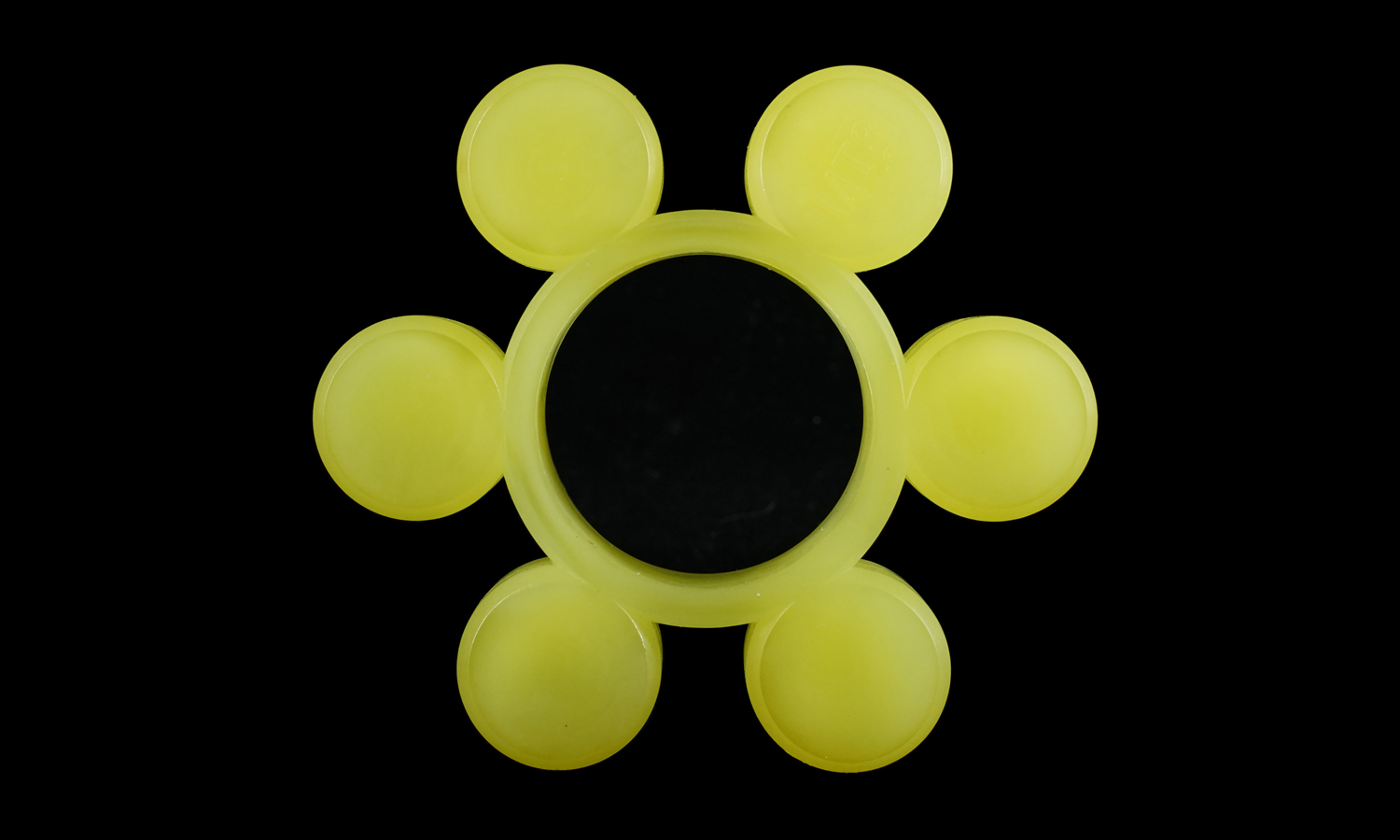

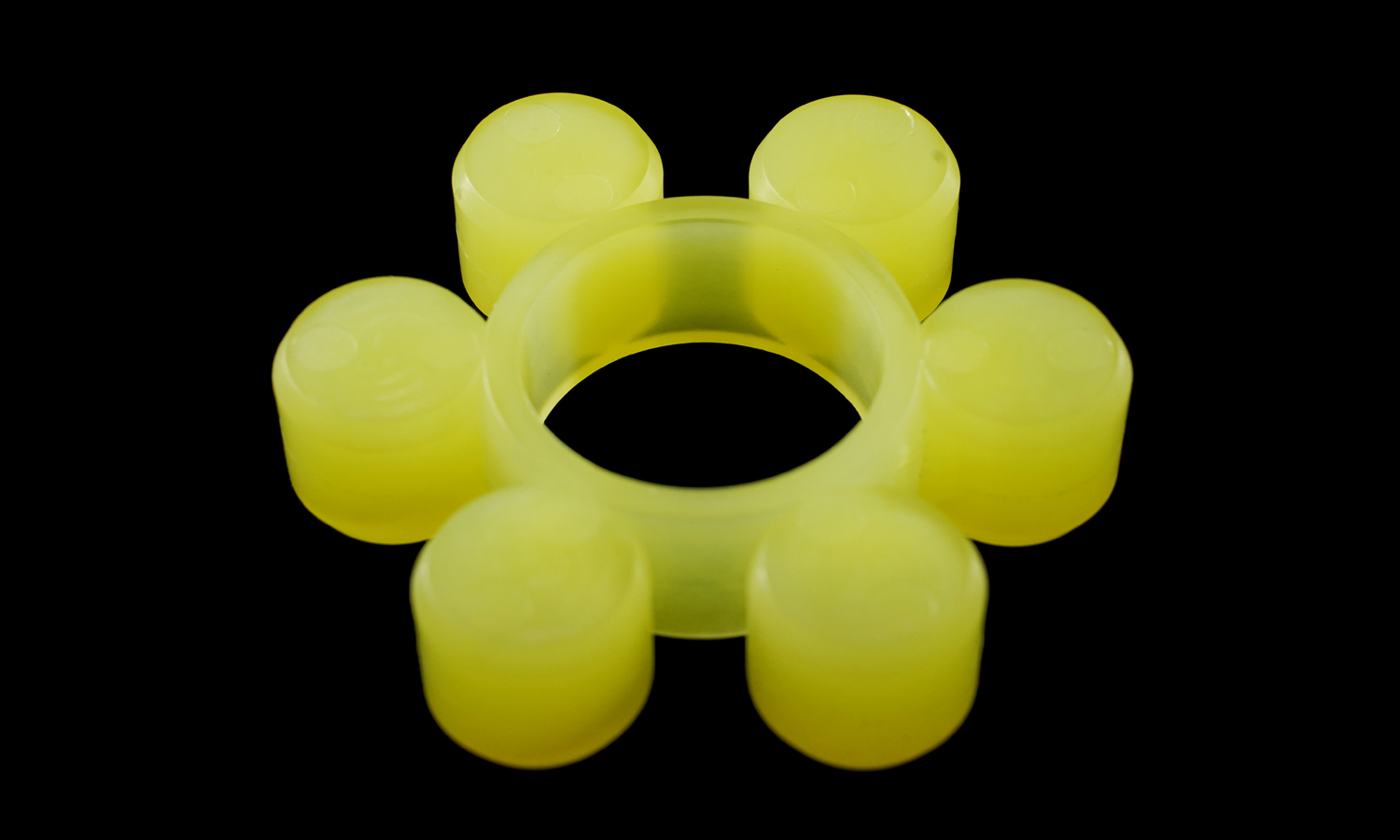

If you are looking for a flexible coupling that can handle high torque, shock loads, and misalignment, you need a jaw coupling with a polyurethane spider. Polyurethane spiders are stronger, tougher, and more resilient than other elastomers. They can also withstand extreme temperatures and harsh chemicals.

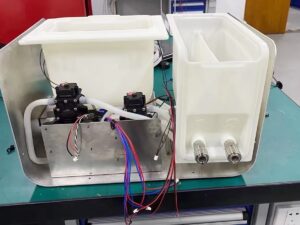

Polyurethane spiders are usually made by open cast molding, which is a simple and precise process that allows for complex and intricate designs. Open cast molded polyurethane spiders are ideal for applications such as pumps, compressors, conveyors, fans, blowers, mixers, generators, and more. They can reduce noise and vibration in the coupling system and extend the life of the hubs and bearings.

But where can you find the best open cast molded polyurethane spiders for jaw couplings? The answer is FacFox. FacFox is a leading provider of custom polyurethane products with over 10 years of experience in the industry.

FacFox can offer you high-quality open cast molded polyurethane spiders with various shore hardnesses, colors, and styles to suit your specific needs. FacFox can also provide you with fast delivery, competitive prices, and excellent customer service. Contact FacFox today to get a quote for your open cast molded polyurethane spider project. You wonŌĆÖt regret it.

Solution

- Step 1: A pattern of the spider shape was placed in sand to create a mold. The pattern and sand were incorporated into a gating system, then the pattern was removed.

- Step 2: Liquid polyurethane was poured into the open mold. The mold was placed into a special oven to heat and cure the polyurethane.

- Step 3: Later, the polyurethane was allowed to cool and harden. Then the polyurethane spider was detached from the mold.

- Step 4: The polyurethane spider was shaved down to the desired finishing. Flaws like overflows would be removed.