- CNC Milled SS304 Male and Female Tube Racing Axle

- CNC Milled HSS Indexable Facing Mill with H-grade Carbide Inserts

Gallery

About Project

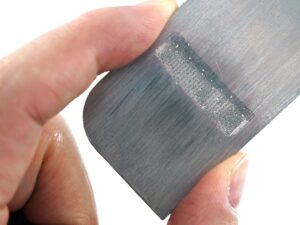

If you are looking for a high-quality and reliable tube insert for your fluid or gas applications, you should consider CNC milled SS316L tube insert. This is a custom-made tube insert that uses SS316L material to create a strong and corrosion-resistant part that can withstand high pressure and temperature.

SS316L is a type of stainless steel that has low carbon content and high molybdenum content, which gives it excellent resistance to pitting and crevice corrosion. Degree male flare is a type of fitting that has a tapered end that can seal tightly with a female flare fitting, creating a leak-proof connection.

This tube insert is especially suitable for applications that require high performance and durability, such as hydraulic systems, pneumatic systems, refrigeration systems, and fuel systems. It can also be used for various industries, such as aerospace, automotive, medical, and oil and gas. It can provide a secure and stable connection for your tubes, pipes, or hoses, while also preventing leaks and corrosion.

If you want to get your own CNC-milled SS316L tube insert degree male flare, you should visit FacFoxãs website. FacFox is a professional online machining platform that offers high-quality and affordable CNC milling service for SS316L material. You can upload your 3D model, choose your material and finishing options, and get an instant quote. FacFox will mill your tube insert with their advanced CNC machines and ship it to you in a short time.

Solution

- Step 1: The CAD model was examined and transformed into a CNC-compatible format with the software AutoCAD.

- Step 2: A most suitable type of CNC machine was chosen according to the complexity of the product design and the cost of the workpiece.

- Step 3: Certain operations were configured and the G-codes were input on the machine. The workpiece was mounted on the machine as well.

- Step 4: The workpiece got shaped automatically. It would be inspected during and after the machining process for quality assurance.