Nanoscribe, now a BICO company, launched the Quantum X shape, a new ultra-precise 3D microfabrication system for rapid prototyping and wafer-scale batch production. With the Quantum X shape, high-precision 3D printing becomes significantly more efficient in terms of printing on wafers up to 6 inches in size. This gain in efficiency is particularly important for a research lab and industrial manufacturing processes such as in life sciences, material engineering, microfluidics, micro-optics, micromechanics, and microelectromechanical systems (MEMS).

Alongside Quantum X, the first Two-Photon Grayscale Lithography (2GL) system, which was launched in 2019 and is specialized in surface patterning, the new Quantum X shape offers improved ultra-precise 3D Microfabrication capabilities. The Quantum X shape enables high-precision additive manufacturing, where accuracy and speed can be optimally balanced to achieve the highest level of productivity and quality. The industry-proven Quantum X platform provides state-of-the-art microfabrication processes from nano- to meso-sized structures and is suitable for wafer-level batch processing.

“With the Quantum X shape, Nanoscribe is setting new standards in wafer-scale high-precision microfabrication for scientific and industrial purposes,” says Dr. Michael Thiel, CSO and Co-Founder of Nanoscribe. “While the Quantum X is already driving the ultra-fast fabrication of flat micro-optics through Two-Photon Grayscale Lithography, we expect the Quantum X shape to make high-precision 3D printing based on Two-Photon Polymerization an unrivaled efficient and reliable tool for rapid prototyping and batch production in research labs and industry.”

3D Microfabrication for highest precision

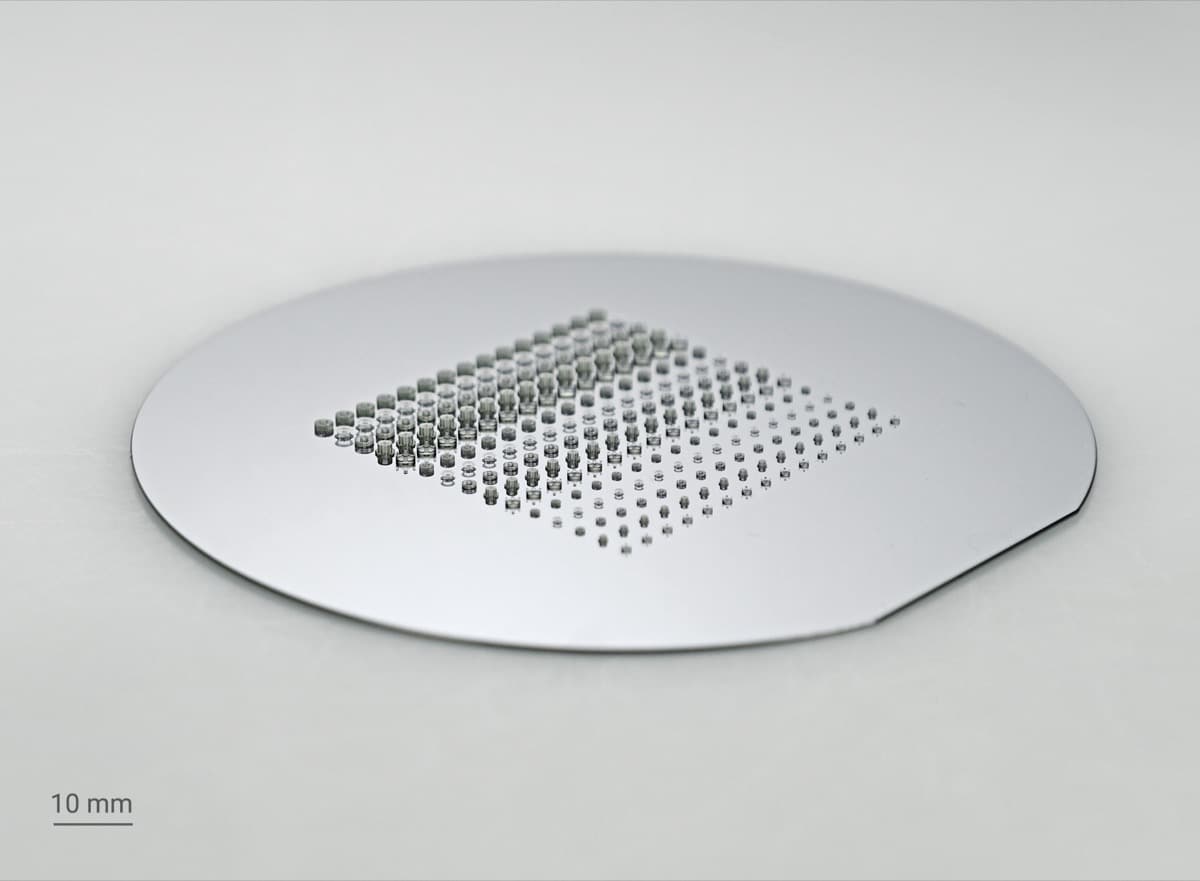

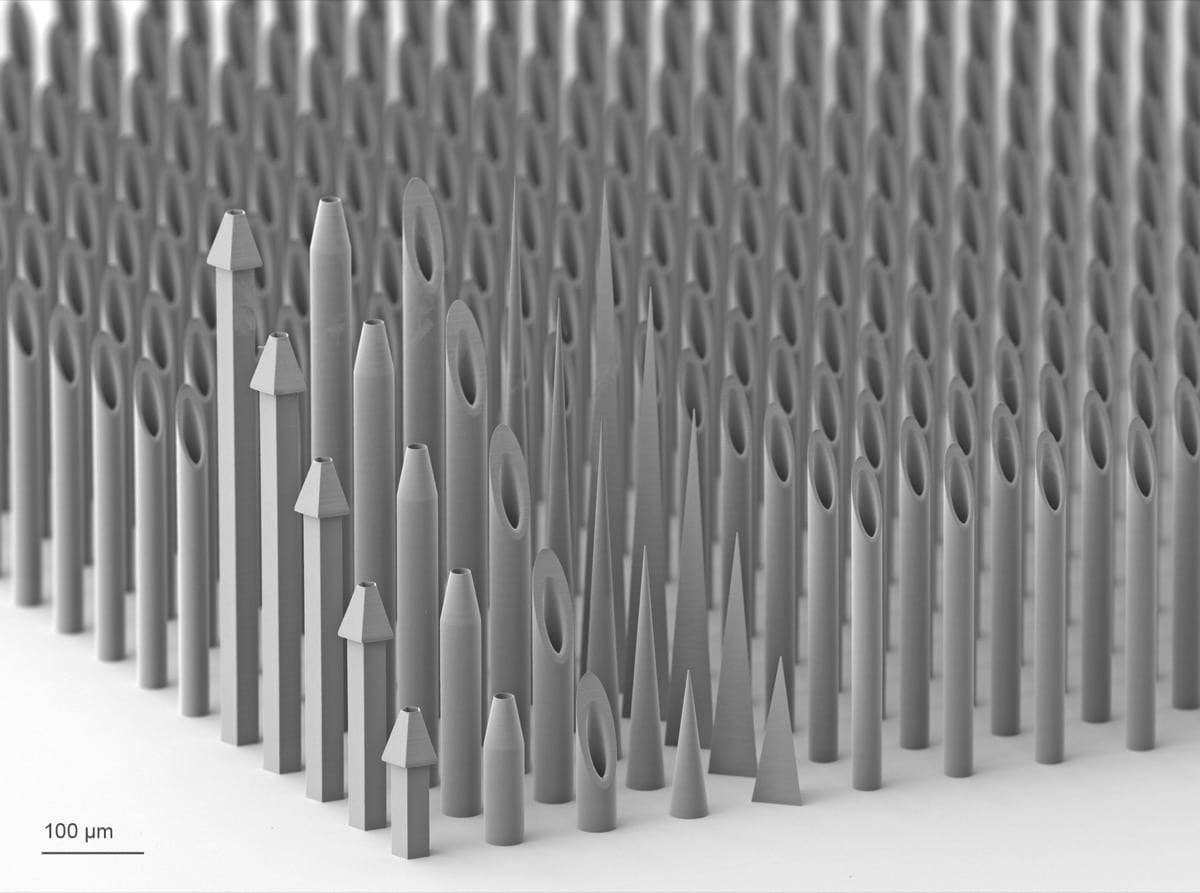

Based on Two-Photon Polymerization (2PP), an additive manufacturing approach providing the highest precision and complete design freedom, the direct laser writing system is optimal for the microfabrication of 2.5D and 3D objects with submicrometer precision on areas up to 25 cm².

The Quantum X shape qualifies as the best-in-class system for ultra-precise 3D Microfabrication of objects with feature size control down to 100 nanometers in all spatial directions for nano- and microscale printing, with the ability for mesoscale printing up to 50 millimeters object size. The machines optimize the interplay between precision and speed to increase output. This is the result of a state-of-the-art galvo system and smart electronics system control units on a sturdy granite-based platform combined with an industry-grade pulsed femtosecond laser.

Manufacturing on Demand

The system features an advanced laser focus trajectory control that accelerates and decelerates the galvo mirror units to the optimum scan speed and dynamically adjusts the laser power at 1 MHz modulation rates.

The new Quantum X shape comes with a unique automatic interface finder, that can detect substrate surfaces with a precision down to 30 nanometers. This unmatched nanoscale accuracy at the highest scan speed, coupled with self-calibration routines, results in reliable and accurate prints within the shortest time.

Simple workflow

As an upright system with an automatic photoresin dispensing function, the printer is the optimal device for industrial batch processes with standard wafers up to 6 inches. The remote access software nanoConnectX brings all the functions and display options of the touchscreen to the systems users’ computers so that they can start, monitor, and control print jobs of connected printers from anywhere.

This reduces preparation time in the lab to a minimum and significantly simplifies group collaboration when sharing a system.

“The launch of the Quantum X shape demonstrates the innovative potential of high-precision 3D printing for many application areas, especially for demanding life science applications,” says Erik Gatenholm, CEO and Co-Founder of BICO. “Nanoscribe is setting new standards in 3D Microfabrication to discover tomorrow’s technologies, and I couldn’t be prouder to have them as a part of our team at BICO.”

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment