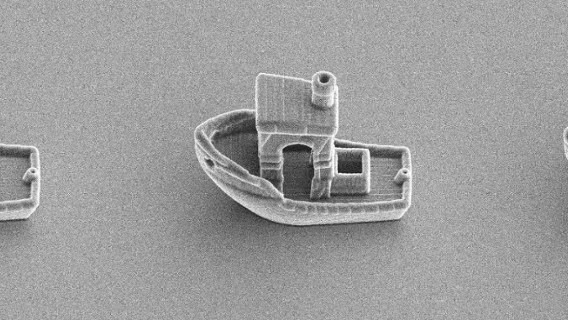

Microfluidic Devices Fabricated by Researchers Using 3D Printing

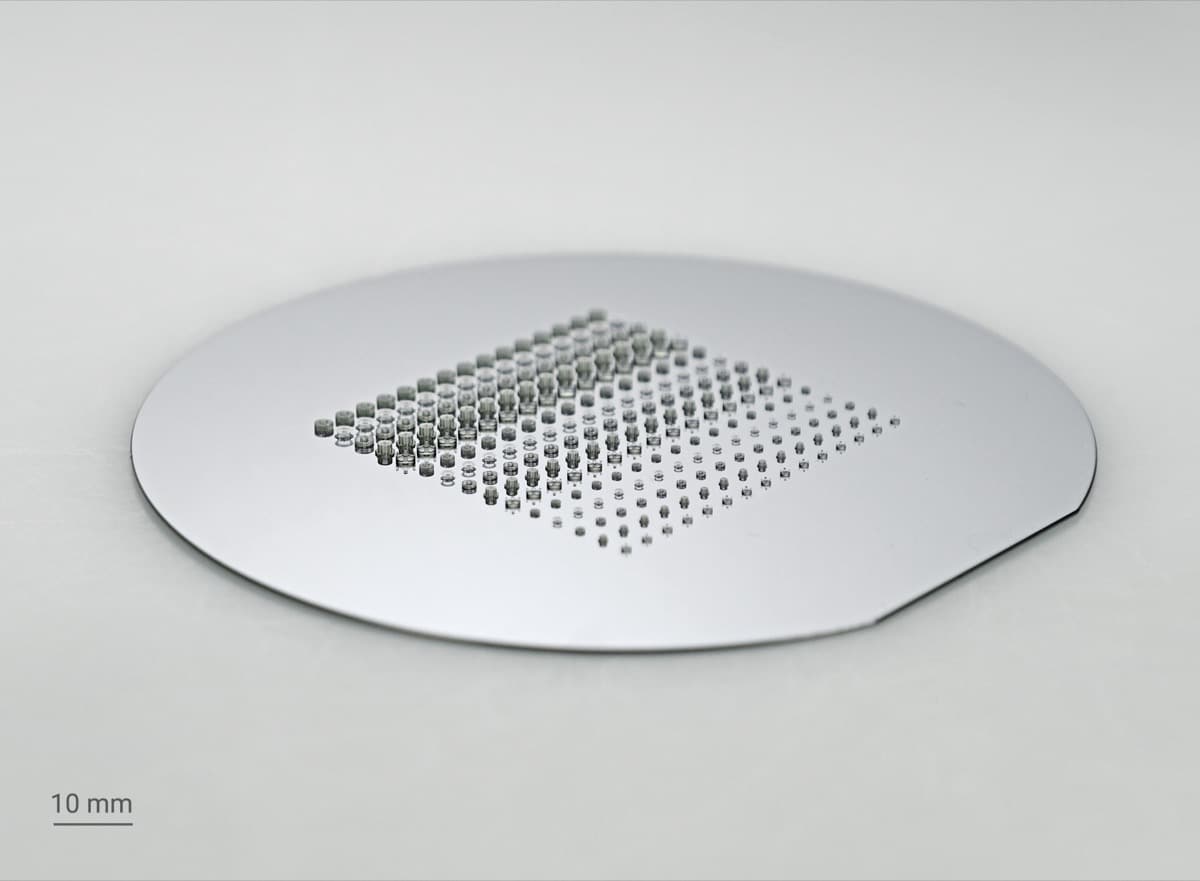

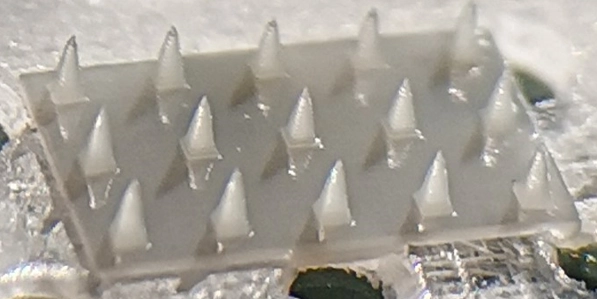

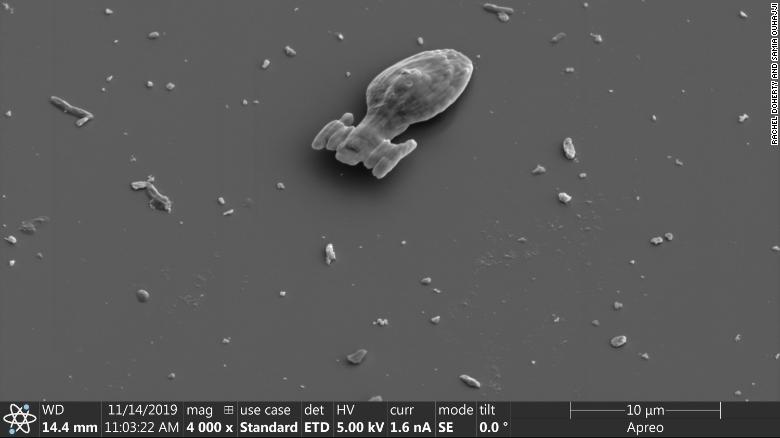

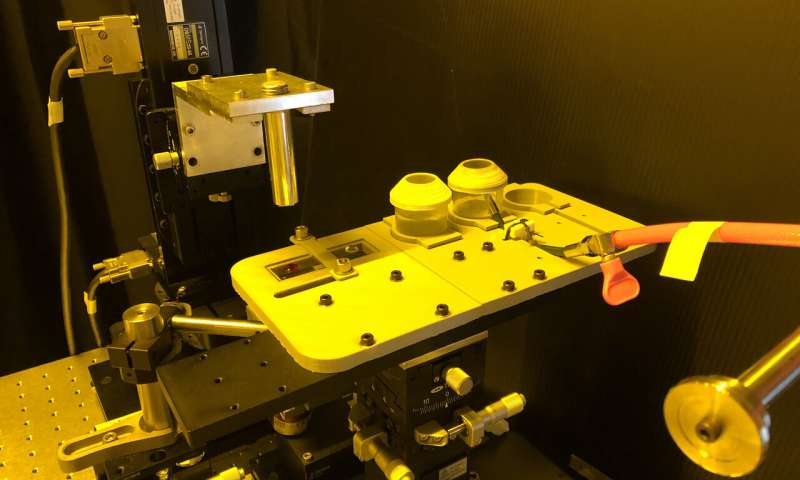

Researchers at the University of Southern California Viterbi School of Engineering have developed a highly specialized 3D printing technique (using vat photopolymerization technology) that allows microfluidic channels to be fabricated on chips at a precise microscale not previously achieved.