Researchers from Yokohama National University (YNU) in Japan have designed a new 3D printing method that can 3D print multi-color microstructures using different materials.

The team’s stereolithography (SLA)-based technique involves suspending several resins into droplets, which allows them to be exchanged during the printing process without causing voids or cross-contamination. Using their novel production technology, scientists have created many multi-material objects in multiple colors, while producing less waste and creating no voids.

In the future, researchers claim that their new printing method can be used to produce a range of optical components, such as sensors and actuators, and even in the healthcare industry.

“Combining multiple kinds of materials can be used to create a function that cannot be realized with a single material,” said Shoji Maruo, Team Leader of the research project at YNU. “Methods like ours, that allow single-step fabrication of multi-material structures eliminates assembling processes, allowing the production of devices with high precision and at a low-cost.”

The appeal of multi-material 3D printing

Using the multi-material 3D printing method, the functions of various different resins can be used to create optimized high-functional structures. In recent years, the enhanced properties exhibited by such objects have led researchers from all over the world to develop their own multi-material printing methods.

Researchers at Columbia University have created another SLS called “Inverted Laser Sintering”, which can sinter multiple powders at once. At the same time, German 3D printer manufacturer Voxeljet optimized its high-speed sintering (HSS) process to provide parts with multiple material properties.

In the past few years, Stratasys has also provided multi-material solutions through its J750 system, which debuted at Formnext 2017. As far as the SLA-based process is concerned, this is a similar story, and many different methods have been introduced, but according to Yokohama scientists, these methods have their own similar flaws. In the existing multi-material SLA, the resin is extruded and then quickly switched in the same channel.

The resulting cross-contamination prevents the resin from being reused and often needs to be replaced, thereby increasing material waste. Although a cleaning process can be introduced to reduce waste, it usually limits the amount of resin that can be used, defeating the goal of multi-material printing in the first place.

The Yokohama team’s novel 3D printing method

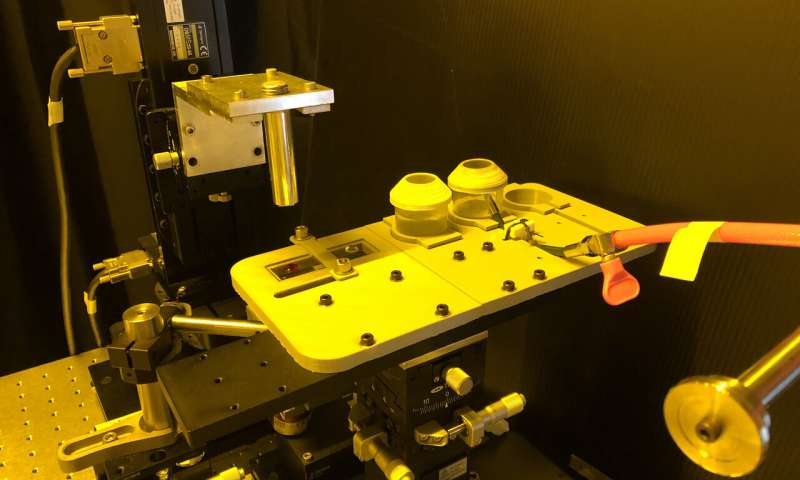

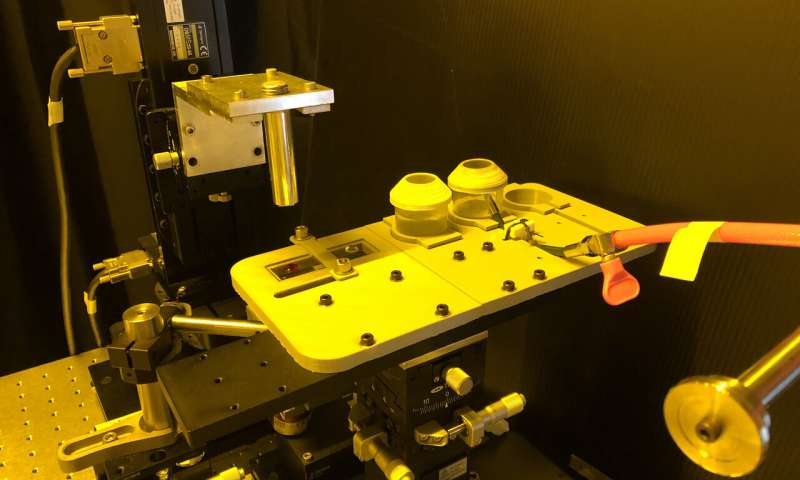

To overcome the shortcomings of the previously developed SLA technology, the Yokohama team developed a two-stage cleaning process. First, the team created a glass palette for storing multiple drops of resin and two washing solvent tanks. The palette is then installed on a linear translation stage, where the air drying unit in the second storage tank is used to dry the material to eliminate any possible cross-contamination.

While testing their novel 3D printing method, the researchers noticed that when they exchanged the light-curable resin, air bubbles began to form in the 3D model. Scientists found it difficult to suppress bubbles by slowing down the process, so they tried to move the model horizontally while keeping the model above the palette with a small gap.

Using their modified production method, the team was able to push bubbles out of the printing area so that the 3D printed objects had no gaps. The researchers then retested their technology by putting a variety of different photocurable resins into their palettes and using them to create various tiny microstructures.

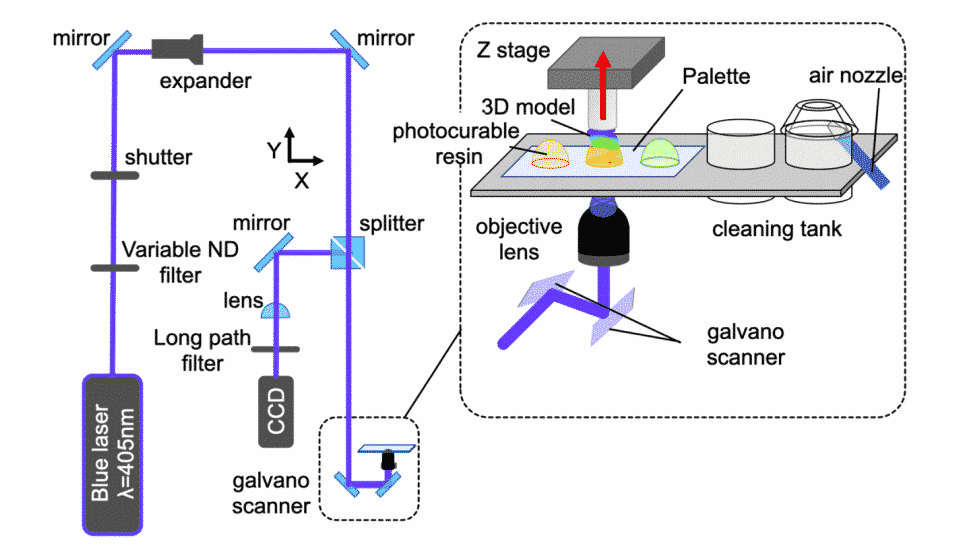

In a six-hour experiment, the research team created a colorful 50-layer cube by exchanging five colors of resin 250 times. A brief evaluation of the 3D printed objects validated the scientists’ approach as they managed to integrate multiple resins into one product without causing any contamination or voids. According to Maruo, the process may be replicated with a variety of other printed materials.

“This method can be applied not only to multicolor resins but also to a wider variety of materials,” said Maruo. “For example, mixing various ceramic micro- or nanoparticles with a photocurable resin can be used to 3D print various types of glass. It could also be used with biocompatible ceramic materials to create scaffolds for regenerating bones and teeth.”

After the team’s initial test was successful, they concluded that their novel SLA 3D printing method was a success. The scientists not only managed to prevent any cross-contamination, but also proved that four different materials can be used simultaneously. The team predicts that in the future, their technology can be deployed in the production of functional end-use devices used in the medical field.

“The ability to make multi-material microscale optical elements using 3D printing could aid in the miniaturization of optical devices used for medical treatments and diagnoses,” concluded Maruo. “This could improve the ability to use these devices in or on the body while also enabling them to be disposable, which would help provide an advanced and safe medical diagnosis.”

The researchers’ findings are detailed in their paper titled “Multi-material microstereolithography using a palette with multicolor photocurable resins,” in the Optical Materials Express journal. The research was co-authored by Taiki Maruyama, Hotaka Hirata, Taichi Furukawa, and Shoji Maruo.