- SLS 3D Printed and Vapor Smoothed Black TPU Holder

- SLS 3D Printed TPU Terminal Block Connector Hub Prototype

Gallery

About Project

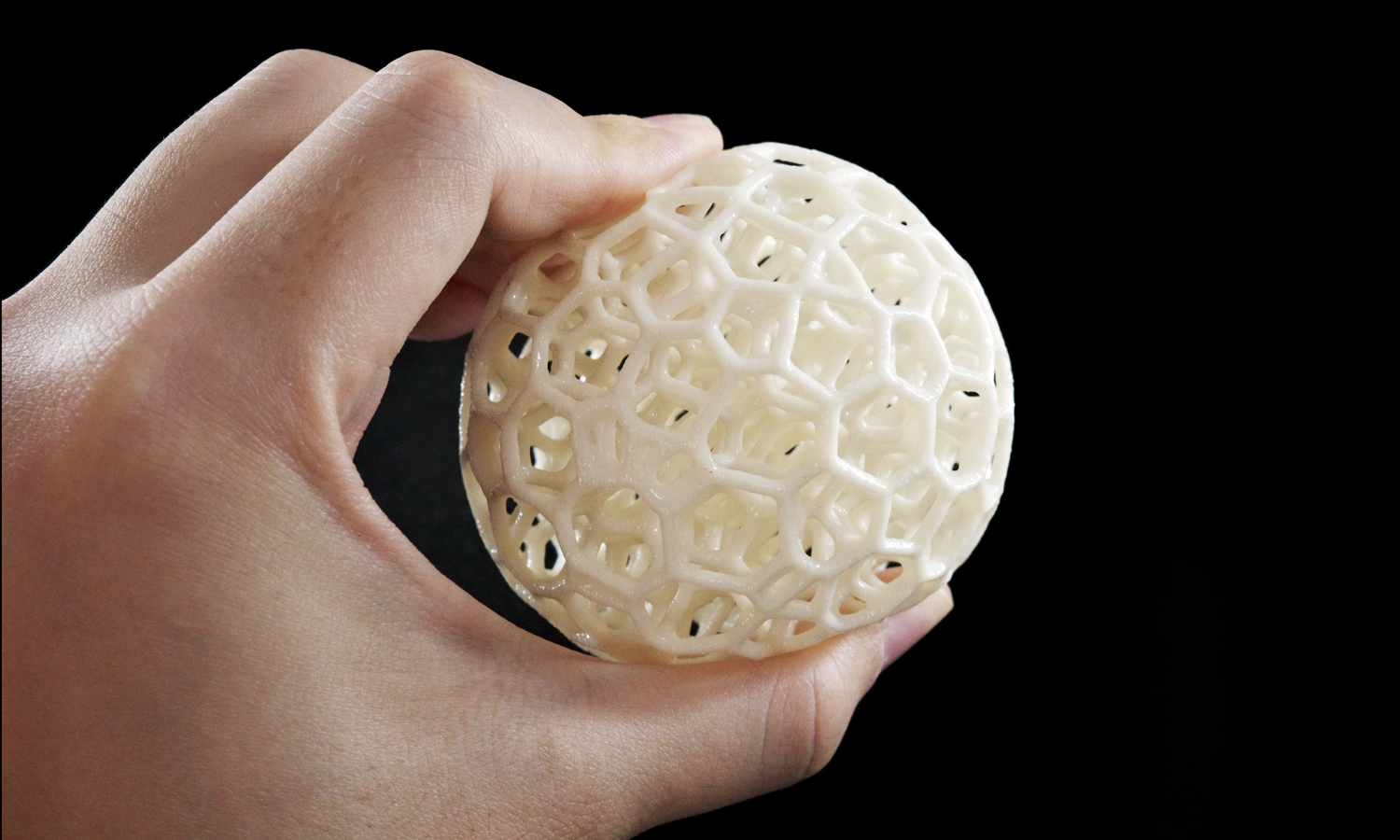

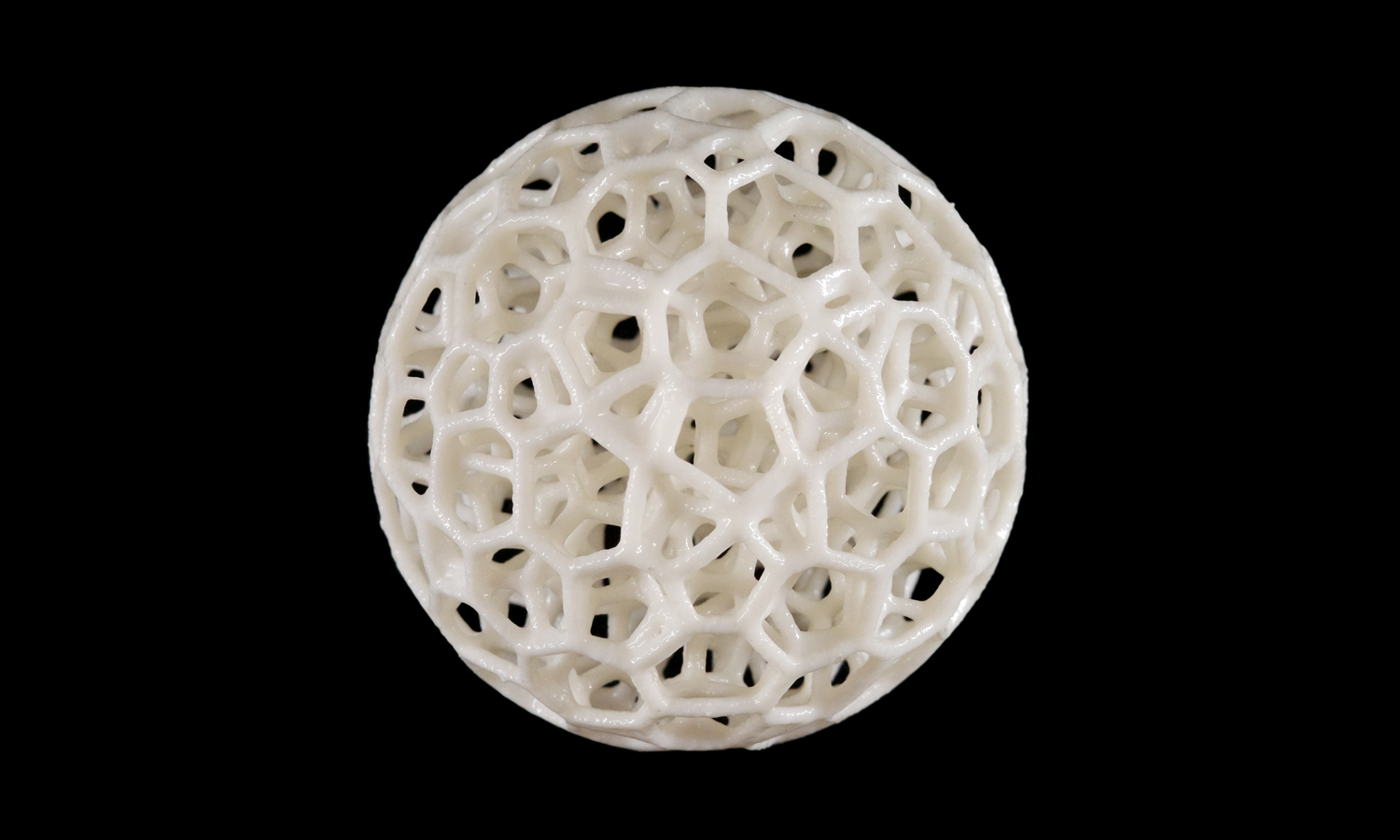

Have you ever wondered how to create a 3D printed ball that is hollow, flexible and shiny? Well, look no further than SLS 3D Printed Vapour Smoothed TPU Hollowed Ball! This amazing product is made from white TPU powder, which is a thermoplastic polyurethane that has excellent elasticity and durability.

The ball is designed with many hexagons that form a honeycomb structure, making it lightweight and strong. But the best part is the vapour smoothing process, which gives the ball a smooth and glossy finishing that is hard to achieve with other methods.

Vapour smoothing is a technique that uses solvent vapour to melt and smooth the surface of 3D printed parts, eliminating layer lines and improving the appearance and performance of the parts. The vapour can also reach all the corners and edges of the ball, making it more uniform and round.

However, since the TPU raw finish is fluffy and porous, the vapour smoothing cannot completely eliminate the unevenness of the surface, so you may still notice some slight variations in the texture. But donãt worry, this does not affect the quality or functionality of the ball, and it actually adds some character and uniqueness to it.

The 3D Printed TPU Hollowed Ball is a great example of how SLS 3D printing and vapour smoothing can create amazing products that are not possible with other methods. If you are interested in this product or want to learn more about TPU manufacturing services, please visit our website facfox.com or contact us via info@facfox.com today. We are happy to help you with your 3D printing needs and answer any questions you may have!

Solution

- Step 1: The ball was designed with a CAD software, using hexagons to form a hollow structure.

- Step 2: The design was sliced into layers and sent to the SLS 3D printer, which used a laser to sinter white TPU powder layer by layer.

- Step 3: The ball was removed from the powder bed and cleaned of excess powder.

- Step 4: The ball was placed in a vapour smoothing chamber, where solvent vapour was circulated and heated to melt and smooth the surface of the ball.

- Step 5: The ball was taken out of the chamber and dried, resulting in a smooth and glossy finishing