- Handheld 3D Scanning Model Aircraft for Reverse Engineering

- SLM 3D Printed 316L Perforated Exhaust Diffuser Components

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 4 workdays

Gallery

About Project

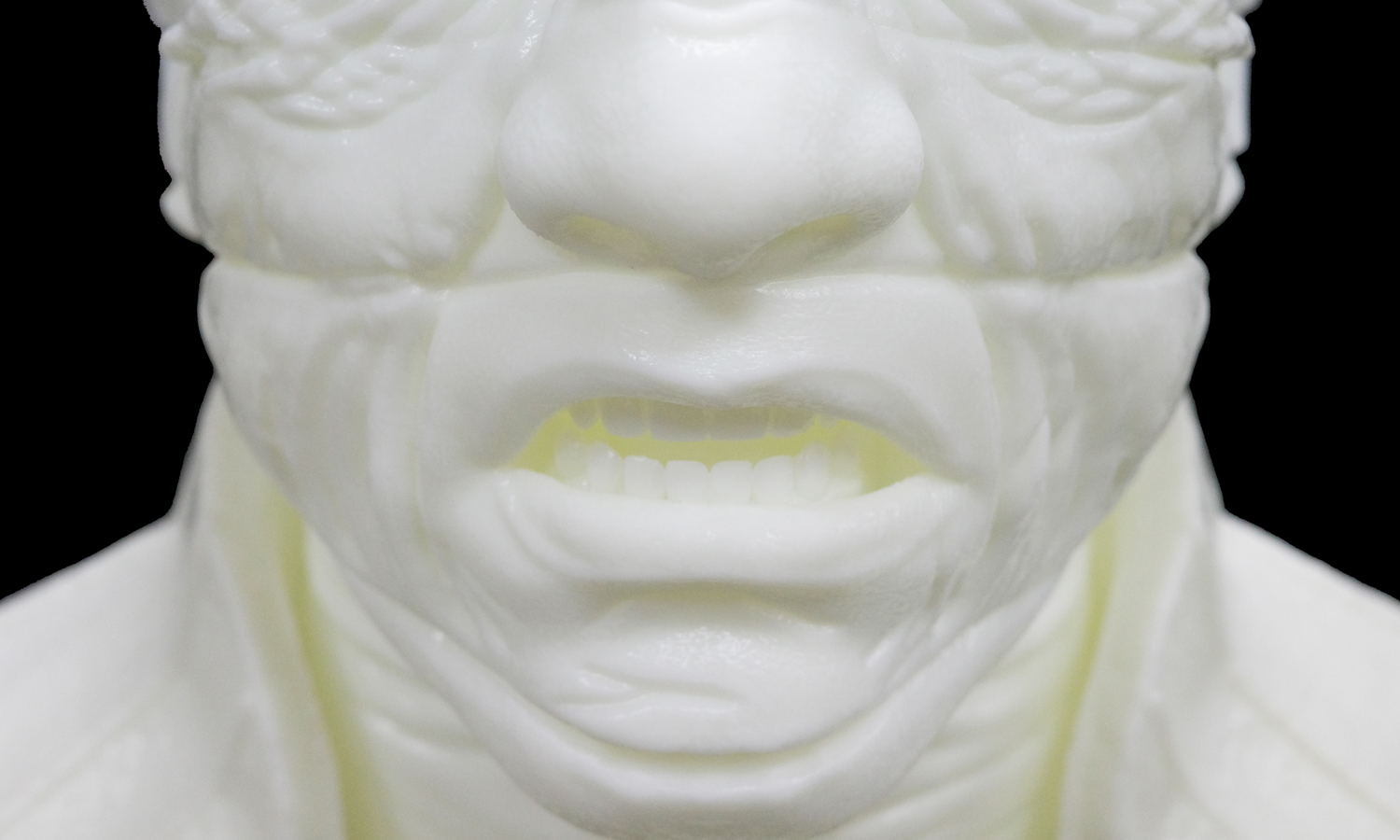

Straight from the disturbing dimension of Clive Barker’s Hellbound: Hellraiser II, this garage kit brings to life the monstrous transformation of Dr. Philip Channard into a full-fledged Cenobite. Portrayed by Kenneth Cranham, Channard undergoes a grotesque rebirth to become one of the most iconic villains in the Hellraiser universe-mechanized, tentacled, and terrifyingly divine.

This 1:1 scale sculpture captures the chilling grandeur of Channard Cenobite with precision and reverence. From the parasitic cranial appendage to the intricate biomechanical details across his twisted visage and armor, the entire bust is a showcase of nightmare-fueled design. Every line, vein, and cable on the character is rendered with immaculate detail-ready to haunt any collector’s shelf or FX studio gallery.

The bust was produced using SLA 3D printing, a process that excels at delivering ultra-high detail and smooth surface finishes. This makes it the perfect foundation for silicone rubber bust production. In this workflow, 3D printed master models are used to create negative molds, into which silicone rubber is cast. The result is a flexible, lifelike sculpture that captures even the most delicate surface textures-ideal for film props, collectibles, and horror FX.

This full-scale resin garage kit was printed for Hellbound Busts, a talented studio dedicated to building hyper-realistic 1:1 horror sculptures using a combination of digital sculpting, 3D printing, and silicone artistry.

If you’re looking to create cinematic-quality props, masks, or busts, FacFox’s SLA 3D printing service offers the perfect launchpad. We specialize in high-resolution resin prints that are tailor-made for mold-making and silicone casting. Whether you’re an artist, FX studio, or indie horror fan, we help turn your terrifying ideas into tangible reality.

¤ÆĆ Start your nightmare build at FacFox.com today.

Solution

- Step 1: The digital sculpt of Channard Cenobite was created using 3D modeling software, capturing intricate anatomical and mechanical details for full-scale production.

- Step 2: The final model file was prepared and sliced using SLA-compatible software, optimizing orientation and supports to preserve surface quality and structural integrity.

- Step 3: The model was printed using SLA (Stereolithography) technology with industrial-grade resin, chosen for its high resolution and dimensional accuracy.

- Step 4: After printing, the support structures were carefully removed, and the surface was gently cleaned to eliminate any residual uncured resin.

- Step 5: The printed parts were then fully cured under controlled UV light to ensure complete material solidification and long-term stability.

- Step 6: Minor imperfections were refined through sanding and surface finishing, enhancing the fidelity of skin textures and biomechanical patterns.

- Step 7: The master print was used to produce a silicone mold, which allowed for casting in flexible silicone rubber for final bust production.

- Step 8: The completed resin print was delivered to the studio, serving as the precise foundation for their 1:1 scale silicone sculptures.