- FDM 3D Printed Red PLA Box with Holes and Slots

- FDM 3D Printed White Polycarbonate Large Spacer Prototype

Material Plastic

Quantity 1 pcs

Price Range $1-100

Lead Time 1 workdays

Gallery

About Project

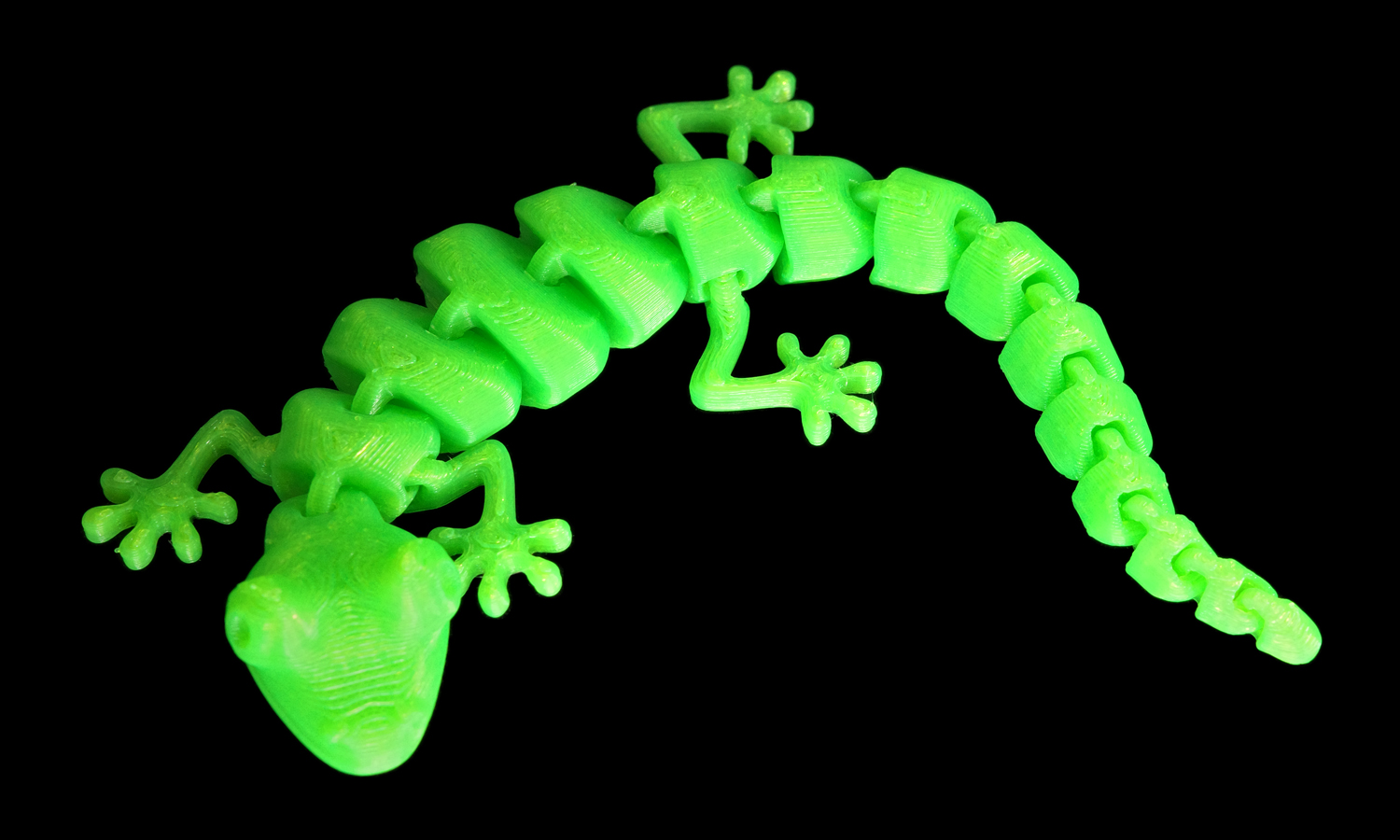

If you are looking for a fun and unique toy to play with or display, you might want to check out the FDM 3D Printed Green PLA Articulated Lizard Toy. This is a 3D printed model of a lizard that has movable joints and can be posed in different ways.┬ĀThe model is based on a popular design by McGybeer that has been downloaded and printed by many 3D enthusiasts. The model consists of 20 parts that are connected by ball joints and snap-fit together. The model is designed to be printed in place, which means that the joints are already functional right after printing and do not require any assembly.

The FDM 3D Printed Green PLA Articulated Lizard Toy is printed with a silky green filament that gives it a realistic and shiny appearance. The filament is made of PLA, which is a biodegradable and eco-friendly material. The only post-processing required for the model is support removal, which can be done easily with a pair of pliers or tweezers.┬ĀIt is a great example of how FDM 3D printing can create amazing and complex models with minimal waste and cost.┬Ā

If you are interested in getting your own FDM 3D Printed Green PLA Articulated Lizard Toy, you can order it from FacFox, a leading online platform for 3D printing services. FacFox offers high-quality FDM 3D printing with fast turnaround time and competitive prices.

You can also customize your order with different options such as material, color, size, infill, and resolution. FacFox will print your model with professional-grade FDM 3D printers and ship it to your doorstep in no time. Whether you need a prototype, a gift, or a personal project, FacFox can help you turn your ideas into reality with FDM 3D printing.

Solution

- Step 1: The 3D model of the lizard was downloaded from MyMiniFactory, a website that offers thousands of ready-to-print models.

- Step 2: The 3D model was sliced using a software that converts it into a series of instructions for the FDM 3D printer. The slicing software also added support structures to the model to prevent it from collapsing during printing.

- Step 3: The FDM 3D printer was loaded with a glossy green filament made of PLA, which is a biodegradable and eco-friendly material. The filament was fed into the extruder, which heated it to a melting point and deposited it layer by layer onto the build plate, following the instructions from the slicing software.

- Step 4: The FDM 3D printer printed the lizard in place, which means that the joints were already functional right after printing and did not require any assembly. The printing process took about 4 hours to complete.

- Step 5: The printed lizard was removed from the build plate and the support structures were carefully cut off with a pair of pliers or tweezers. The support removal also revealed the layer lines, which added some texture and character to the model.