- PolyJet vs Binder Jetting 3D Printed Taylor Swift Full-color Head Sculpture

- PolyJet vs Binder Jetting 3D Printed Full-color Head Sculpture of Noblewoman

Gallery

About Project

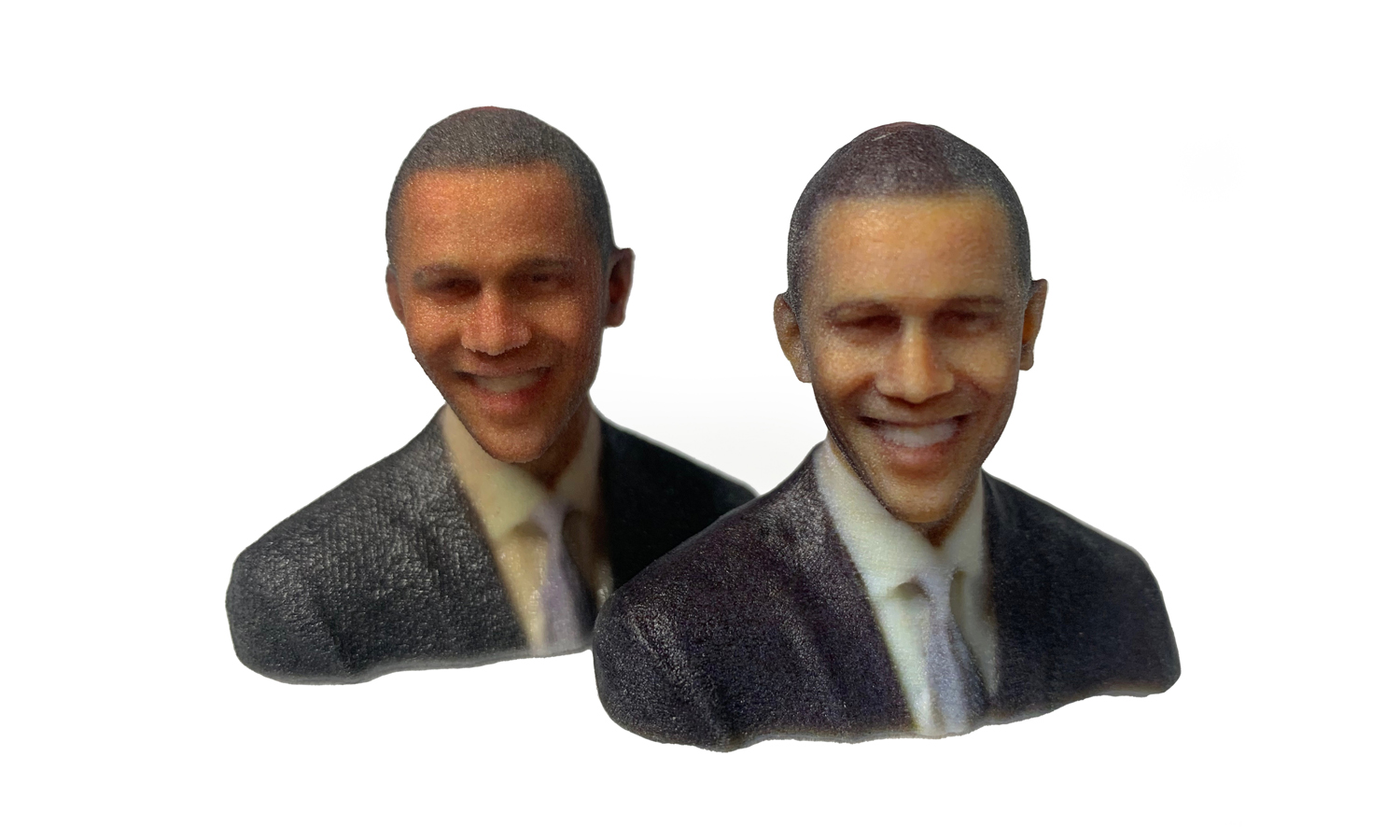

Do you want to have a 3D printed Obama Barack head sculpture on your desk or shelf? If yes, then you should check out our amazing products at FacFox!

We have two different methods of printing colorful statues without extra painting: PolyJet and Binder Jetting. Both of them can produce realistic and detailed models of the former president, but they have some pros and cons.

PolyJet 3D printing technology uses PolyJet Multi-Color Resin material, which is a photopolymer that hardens when exposed to UV light. This method can create smooth surfaces, light colors, and clear details. However, it is also more expensive than Binder Jetting.

Binder Jetting 3D printing technology uses CJP Fullcolor Sandstone material, which is a powder that binds together when sprayed with a liquid agent. This method can create rough textures, dark colors, and visible layer lines. It also has some flaws on the nose and shirt of the model. However, it is also cheaper than PolyJet.

You can see the comparison of these two methods in the pictures below. The PolyJet one is on the right and the Binder Jetting one is on the left.

Which one do you prefer? If you like a smooth, light-colored, and detailed model, then you should go for PolyJet. If you like a rough, dark-colored, and cheap model, then you should go for Binder Jetting.

At FacFox, we can custom statues for people¤æ®ŌĆŹ¤”░¤æ©ŌĆŹ¤”▓¤æĄ¤ÅŠ¤æȤÅ╗ , pets ¤ÉČ ¤É▒ ¤É░ ¤É╣ , houses ¤ÅĀ ¤ÅĪ ¤Åś’ĖÅ , etc. Just send us your photos or 3D files and we will print them for you with high quality and fast delivery. You can choose from various materials and colors to suit your preferences.

DonŌĆÖt miss this opportunity to own a 3D printed Obama Barack head sculpture or any other statue you want! Visit our website today and order yours now!

Solution

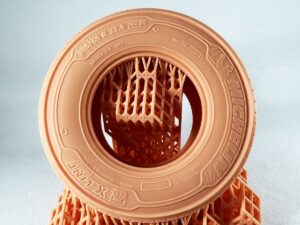

The process of Binder Jetting 3D printing full-color sandstone sculpture:

- Step 1: As the default layer thickness is 0.1mm and sandstone prints have medium tolerance, the thickness of all the modeling details was examined to ensure they can all be printed out.

- Step 2: A rolling batch left a uniform layer of sandstone-like powder. From there two printing heads passed over the batch, coloring and adhering to the object at the same time. The batch of powder then made another pass, until the object was completed.

- Step 3: After printing, the statue was then coated with cyanoacrylate (super glue) or a different infiltrant to improve part strength and enhance the vibrancy of the colors. A secondary epoxy layer could then also be added to further improve strength and color appearance.

The process of PolyJet 3D printing full-color resin sculpture:

- Step 1: The CAD file was imported into the slicer software. Its positioning was arranged and necessary supporting structures were added. Soluble PolyJet supports could help create complex models with no restrictions on geometry.

- Step 2: A inkjet-type head deposited multiple droplets of Vero (white) and Agilus (black) onto the build plate, which was then cured by a UV light. After a thin layer was created, the process repeated itself by jetting additional layers until the part was fully formed.

- Step 3: The supporting structure was removed by rinsing the model with water and isopropanol (IPA). The parts would need post-cure under UV light for optimal properties.