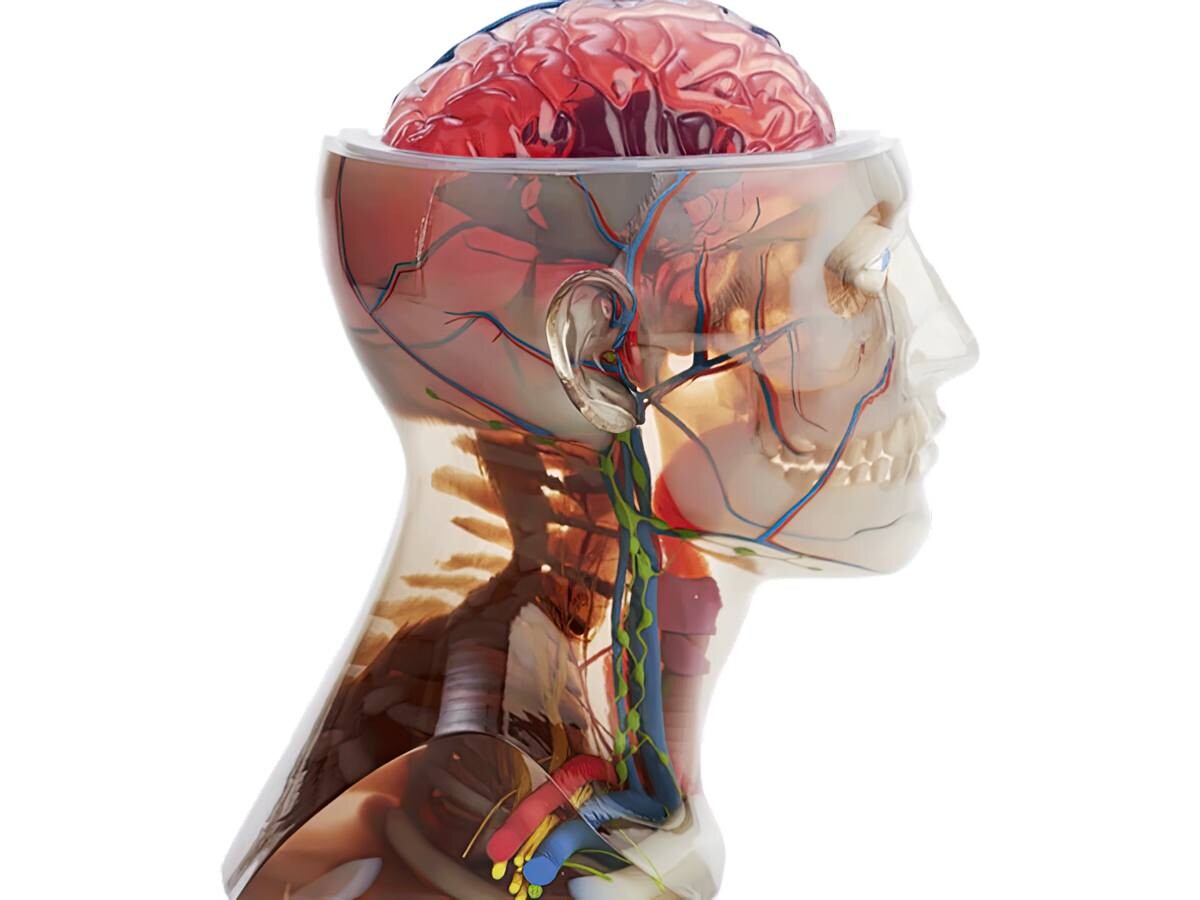

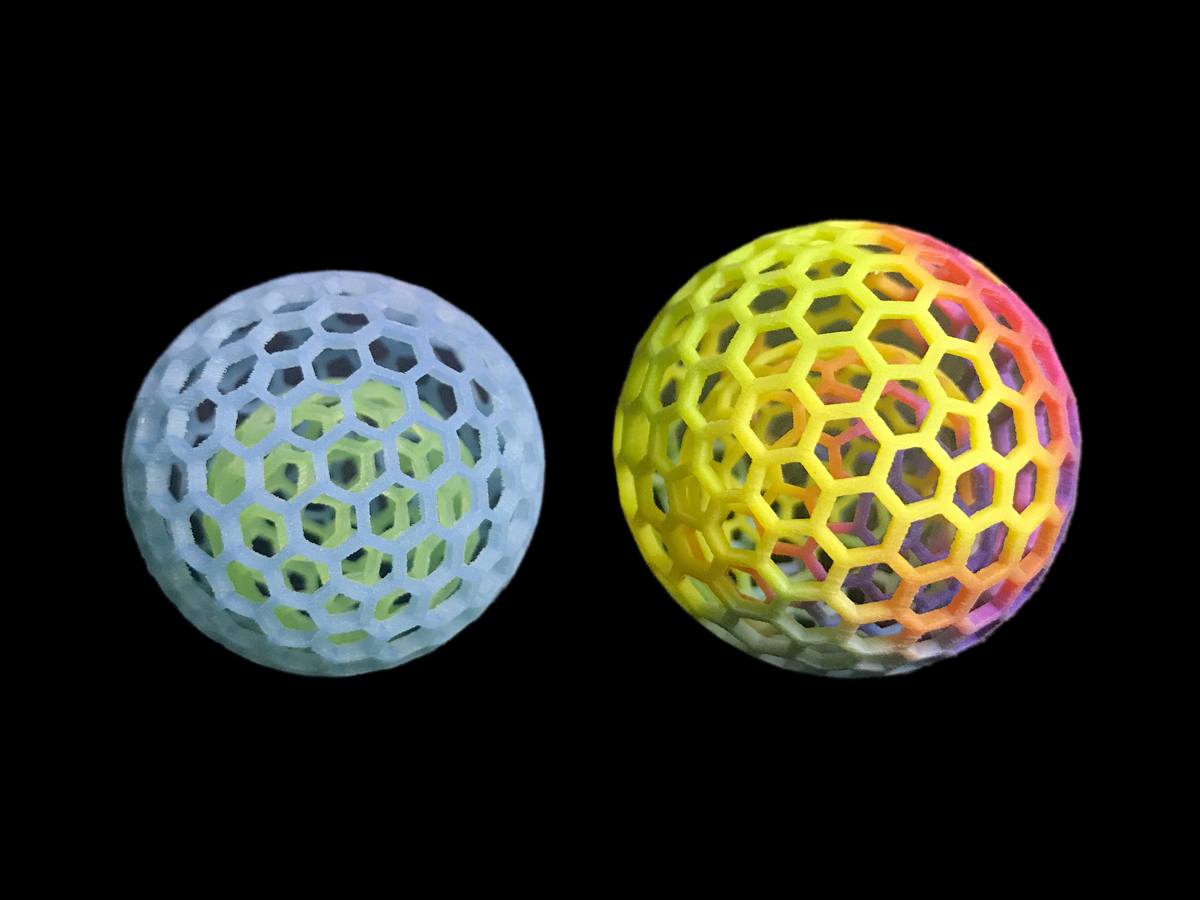

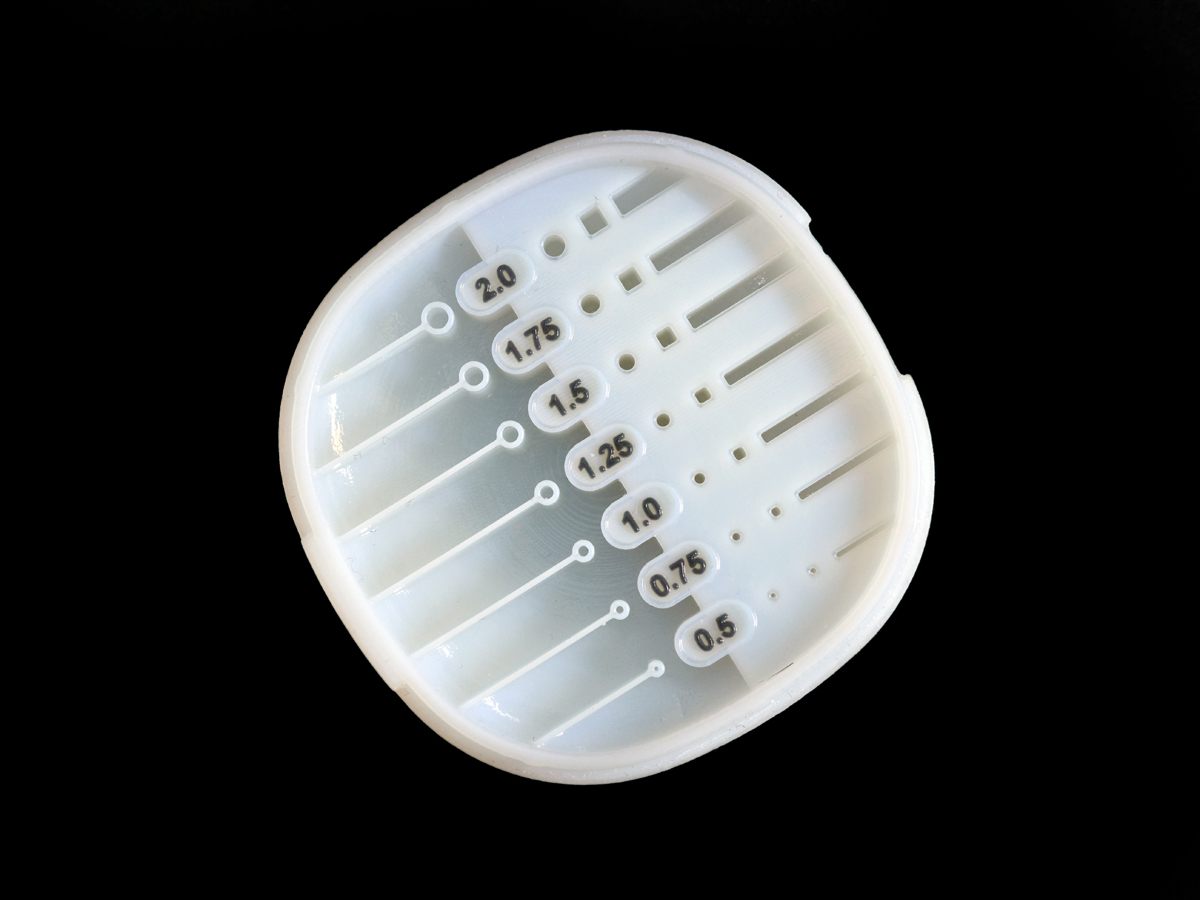

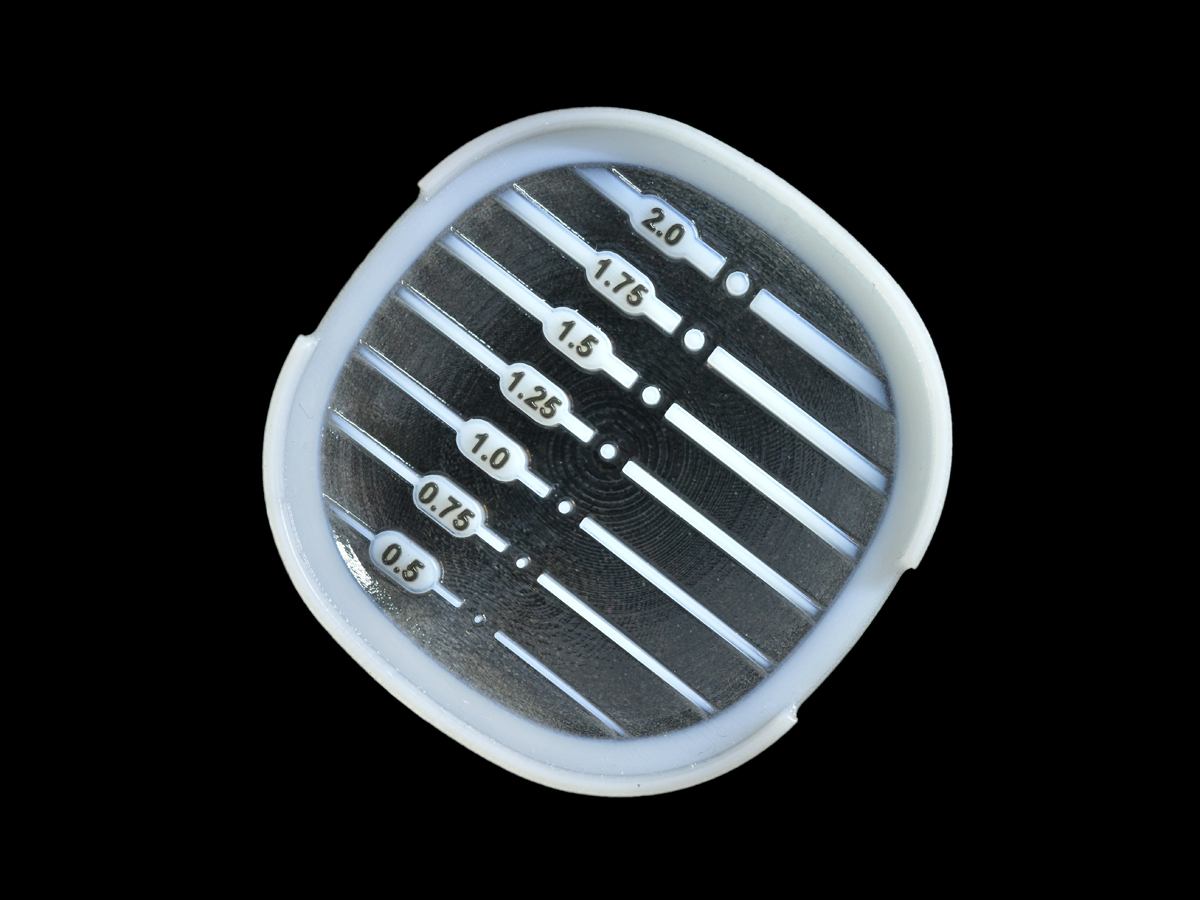

PolyJet Full-Color ResinStratasys Vero+Agilus Create colorful and multi-material prototypes that look, feel and operate like finished products, without the need for painting or assembly. Max Build Size Min Build Size 5 x 5 x 5 mm Default Layer Height 0.016 mm Optional Layer Heights 0.016, 0.032 mm Tolerance ┬▒0.2% (with a lower limit of ┬▒0.2 mm) Up to 50 Ōäā Smooth ŌśģŌśģŌśģŌśģŌśģ Detail ŌśģŌśģŌśģŌśģŌśģ Accuracy ŌśģŌśģŌśģŌśģŌśģ Rigidity ŌśģŌśģŌśģ Flexibility ŌśģŌśģŌśģŌśģ Available ColorsColorful

Available Post ProcessSuitable For Complex designs with intricate details, Not Suitable For Large models, Additional InfoUnmatched Product Realism Maximum Versatility

Feature

3D PrinterMaterial Spec Sheet

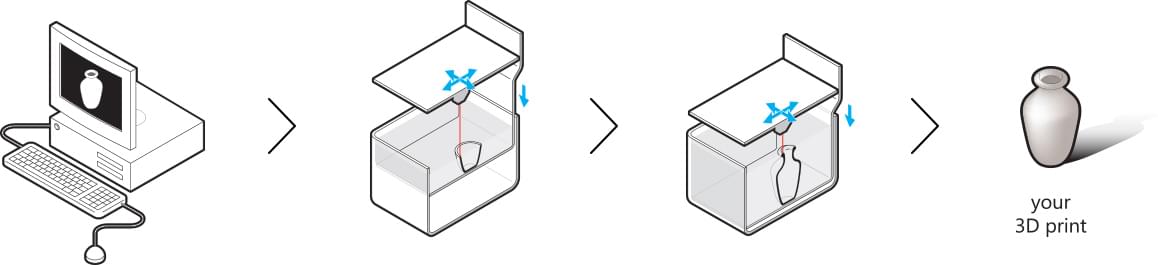

PolyJet prototyping technology is used to build your design with this material. Stratasys’ patented PolyJet inkjet technology works by jetting photopolymer materials in ultra-thin layers onto a build tray, layer by layer until the model is completed. Each photopolymer layer is cured by UV light immediately after being jetted, producing fully cured models that can be handled and used immediately. The gel-like support material, which is specially designed to support complicated geometries, can easily be removed by hand and water jetting.

|