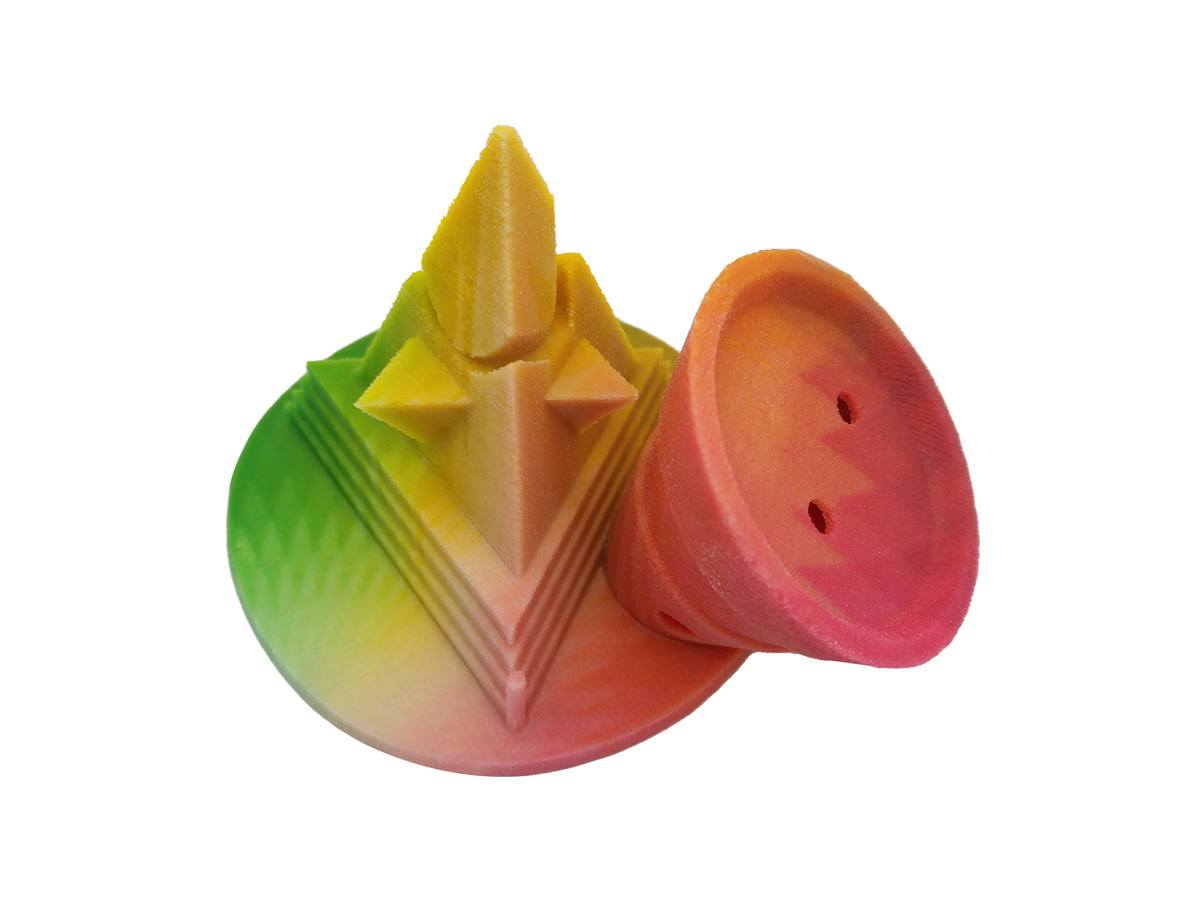

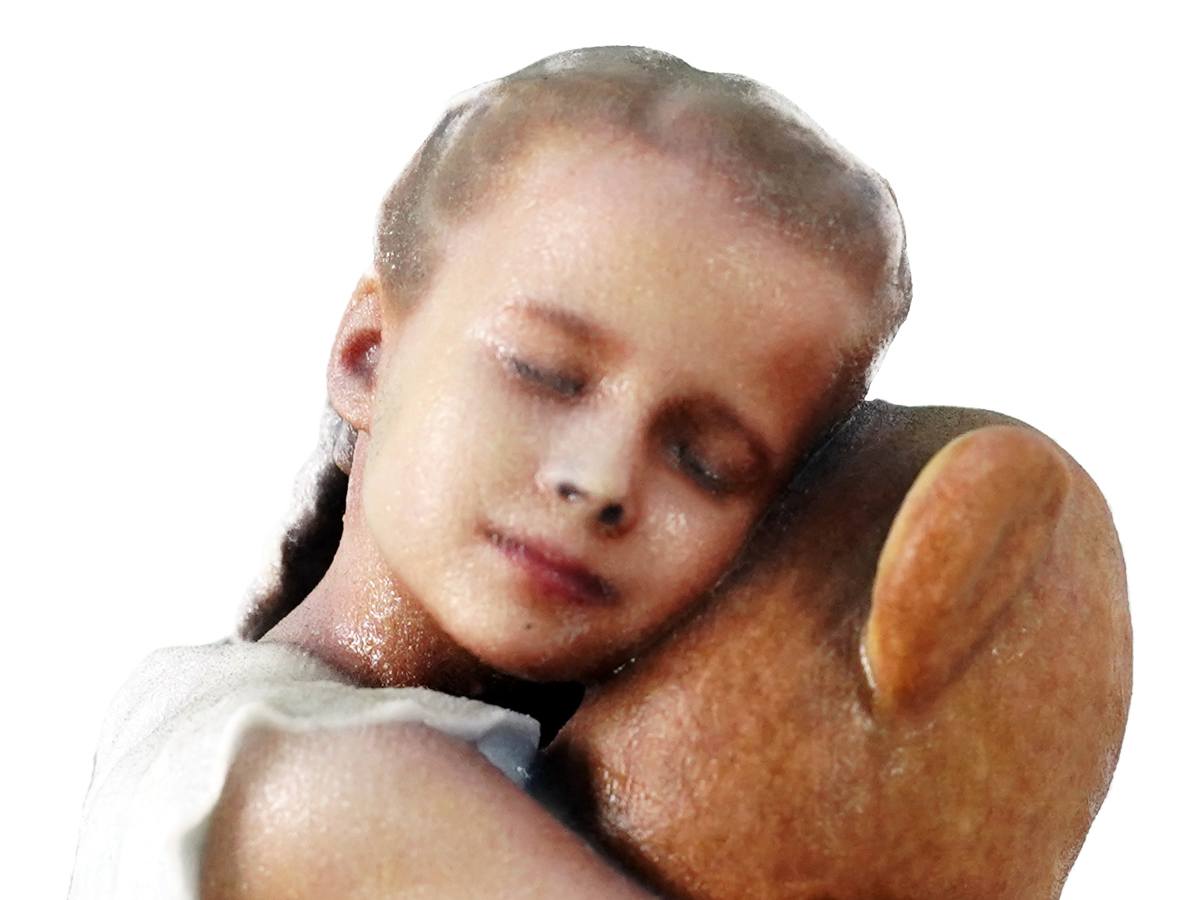

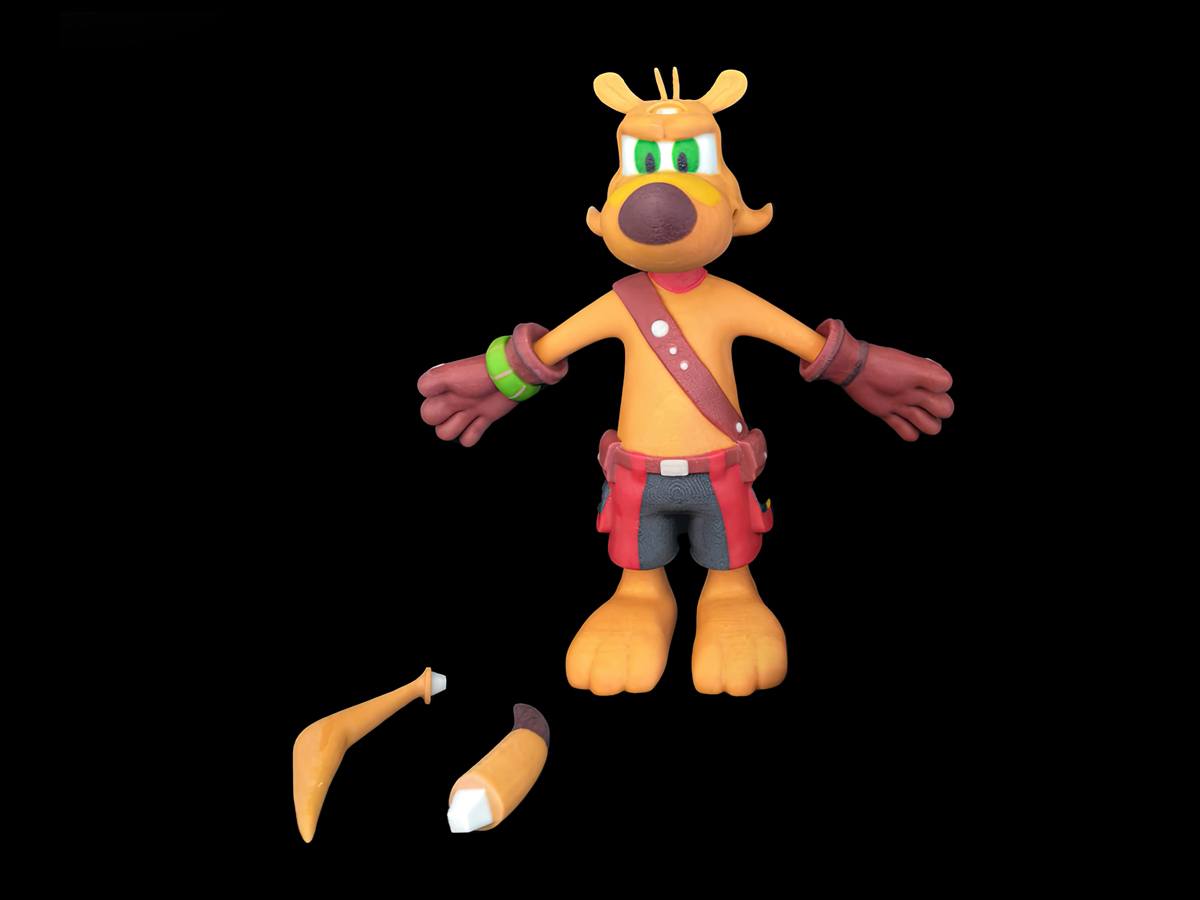

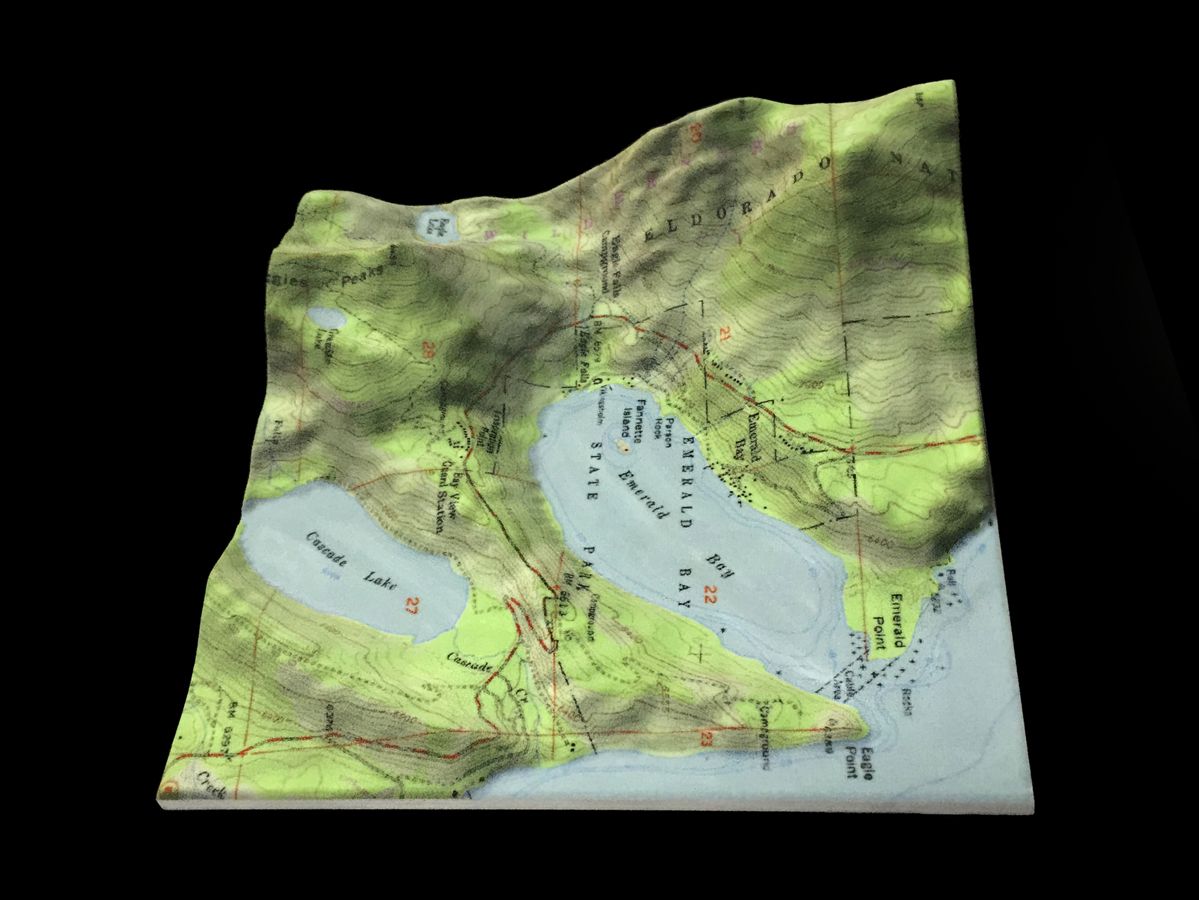

CJP Full-Color Sandstone3D Systems VisiJet PXL Sandstone is one of the few materials capable of full-color 3D prints. It is perfect for figurines, life-like models, avatars, and other products that lend themselves to colorful, high-quality printing. Max Build Size Min Build Size 10 x 10 x 10 mm Default Layer Height 0.1 mm Optional Layer Heights 0.1 mm Tolerance Medium (Not specified) N/A Smooth ŌśģŌśģŌśģ Detail ŌśģŌśģŌśģŌśģ Accuracy ŌśģŌśģŌśģ Rigidity Ōśģ Flexibility Ōśģ Available ColorsColorful

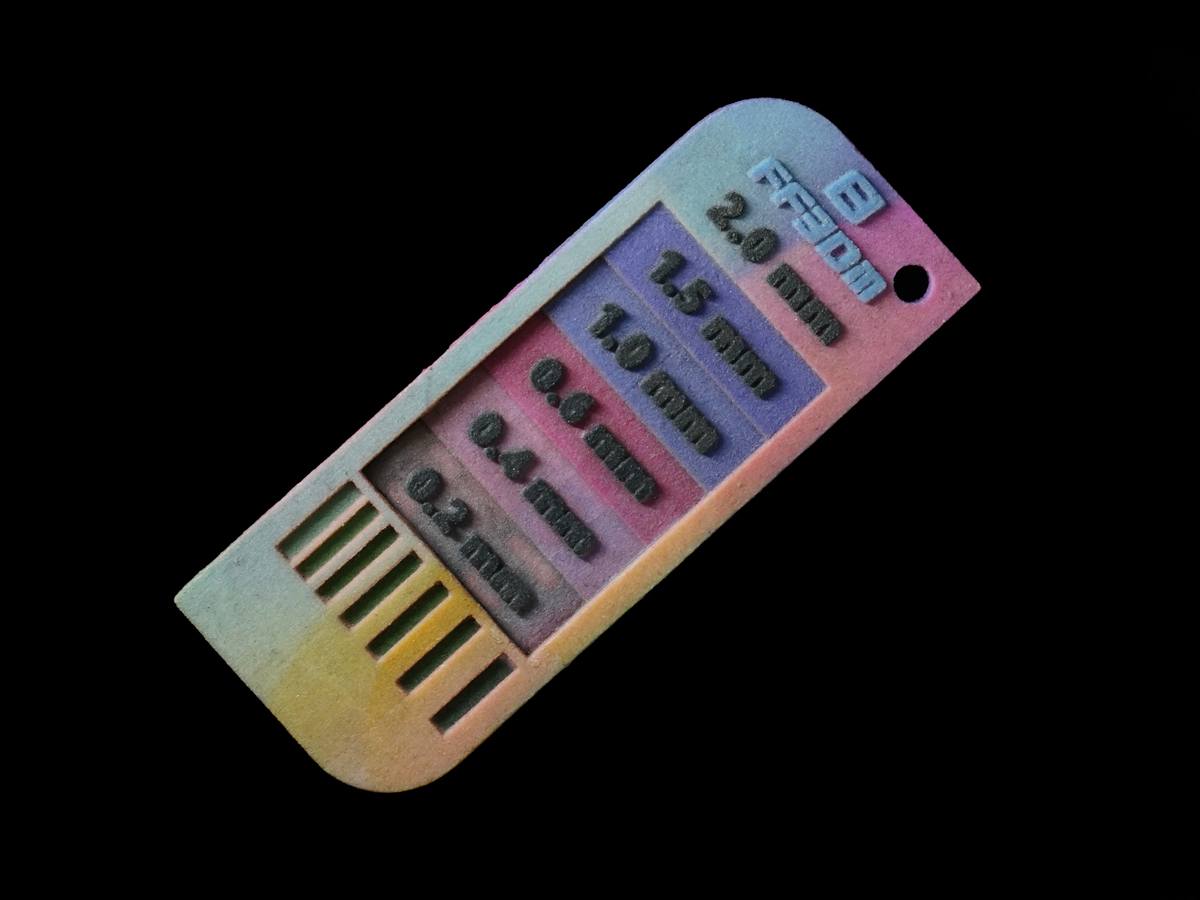

Available Post ProcessSuitable For Sales, marketing and exhibition models, Not Suitable For Functional prototypes and end products, Additional InfoIf your 3D file doesnŌĆÖt contain any color information, it will result in a slightly off-white/grayish print. For multicolor, you must either upload a file that already includes the textures (e.g. colored STL, VRML, SKP, X3D, and DAE) or a ZIP file containing all the necessary color information (e.g. an OBJ file with a texture map and an MTL file). Please consult our design guide for more information about textures. The model needs to be handled with care. Even after reinforcing the model with superglue, the model stays fragile and has problems absorbing shocks. Take into account that the walls of your model need to be 1.7 to 2 mm thick and the details of imprints can be 0.8 to 1 mm. Long, delicate features like pins, thin fingers, tiny hair points or antennas that are 0.8 to 1.7 mm and stick out might not survive the process. Exposure to direct sunlight will cause your multicolor model to fade over time. Moisture will ruin the color of your model. Skin tone colors and black are difficult to reproduce, so some variation in color will occur.

Feature

3D PrinterMaterial Spec Sheet

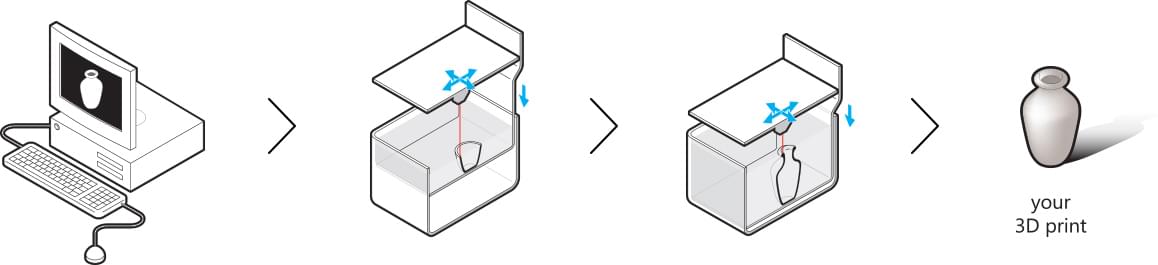

ColorJet(Binder Jetting) Printing builds up the model from bottom to top, layer by layer. A roller puts a thin layer of powder on a platform and a print head places tiny drops of glue at specific locations, printing a thin layer of your model. The platform lowers and the roller spreads another layer of powder. The coloring is done by combining 4 different pre-colored types of glue to match the requested color. The surface can have almost any color since the printer prints up to 24-bit colors, equal to 16.7 million different colors. After the printing process, the model is brittle but is strengthened by putting it into superglue. A UV coating is sprayed on it to prevent decoloration by sunlight.

|