- ColorJet 3D Printed Sandstone Replica of Chinese Antique Wall Plaque Phoenix and Dragon

- ColorJet 3D Printed Young Lady Full-color Sandstone Statue

Gallery

About Project

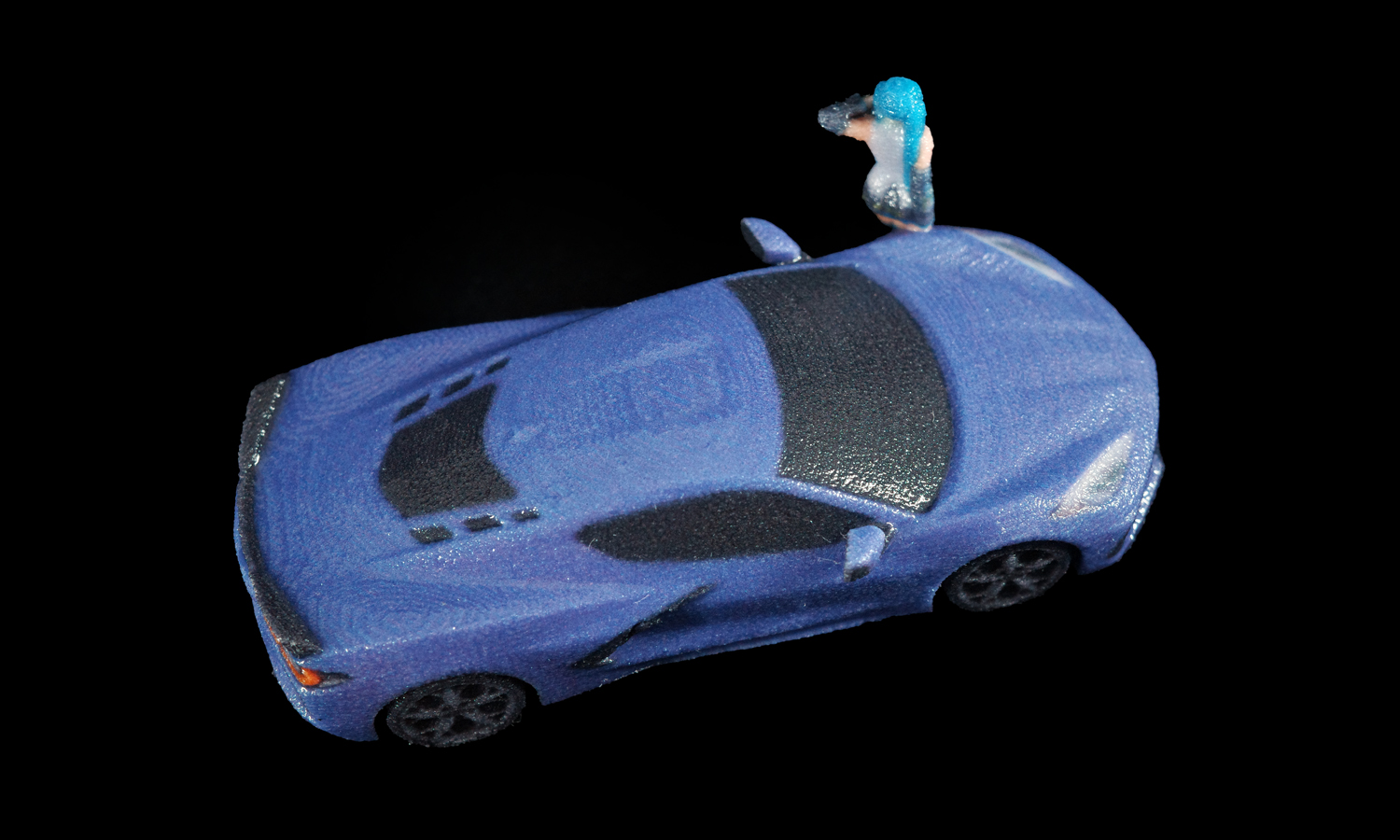

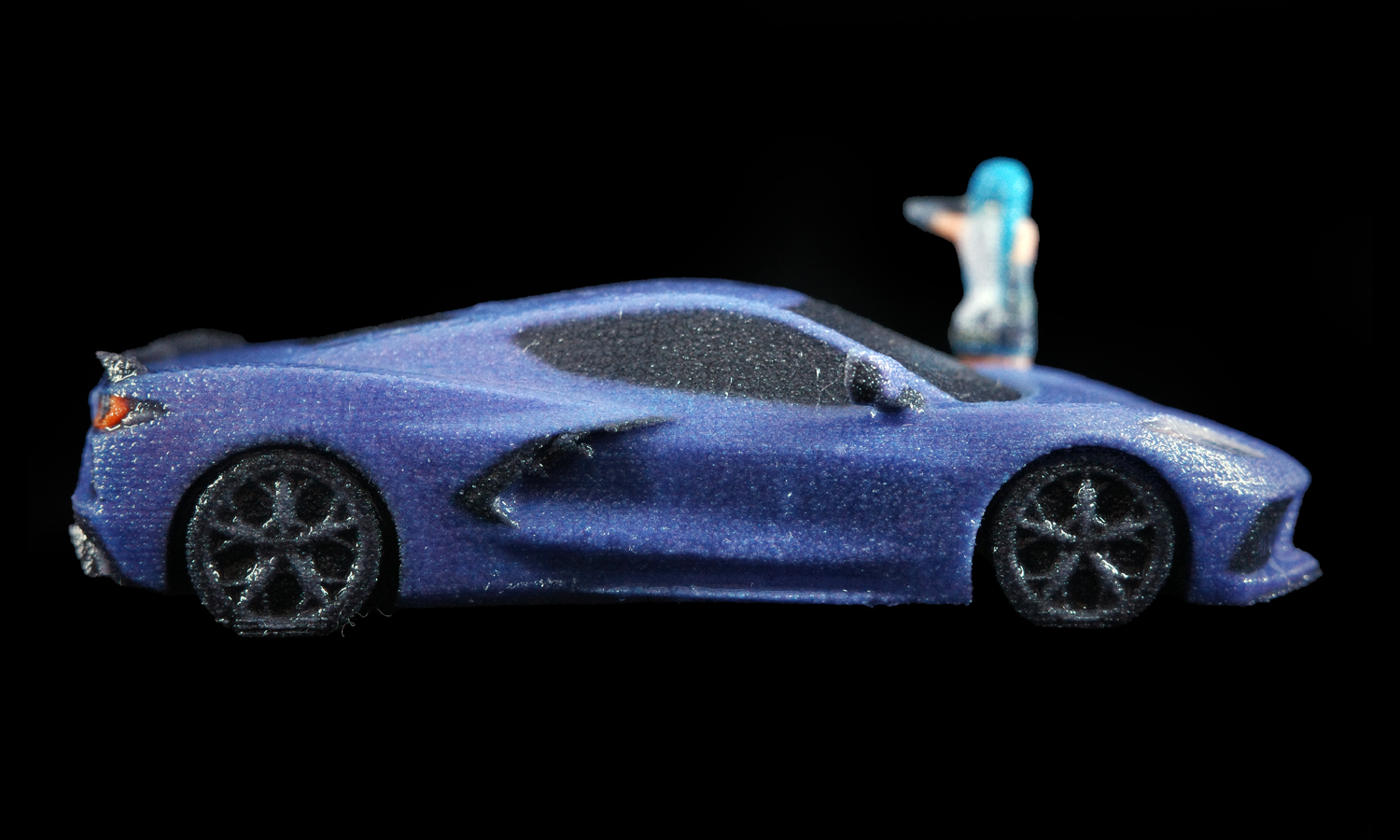

Have you ever dreamed of owning a blue Chevy Corvette, the iconic American sports car? Or maybe youŌĆÖre a fan of Miku, the virtual pop star from Japan? Well, now you can have both in one amazing 3D-printed miniature!

This is the Colorjet 3D Printed Blue Chevy Corvette and Miku Fullcolor Sandstone Miniature, a stunning display of 3D printing technology and creativity. The figurine and the car miniature are printed in one piece and in full-color, no need to be handpainted. The details are incredible, from the shiny paint of the Corvette to the expressive face of Miku. Miku is standing in front of the carŌĆÖs left front light, opening her palm and putting it near her face, acting in a photo pose. She looks like sheŌĆÖs having fun with her new ride!

Colorjet technology is a 3D printing method that uses powder and binder to create full-color models. The binder contains color pigments and is jetted over the powder, which solidifies and forms the model. Colorjet technology can produce realistic and high-resolution models for various purposes, such as concept models, architectural models, educational models, and art models. Colorjet technology can also create personalized and customized statues, such as the Colorjet 3D Printed Blue Chevy Corvette and Miku Fullcolor Sandstone Miniature. You can choose your own character, design, pose, and size, and get a unique 3D printed statue in full-color.┬Ā

Do you need a quick, affordable, and flexible full-color figurine manufacturing service? Contact us today and get a quote for your small batch production. Just send your files to info@facfox.com for more details.

Solution

- Step 1: The 3D model of the Corvette and Miku was created using 3D modeling software, such as Blender, Maya, or ZBrush. The model was scaled to the desired size and FacFox would recommend a solution and give a quote that was tailored for the client’s requirements.

- Step 2: The 3D model was exported to a file format that was compatible with the Colorjet 3D printer, such as STL, OBJ, or VRML. The file was then uploaded to the 3D printerŌĆÖs software, where the model was sliced into thin layers and assigned colors for each layer. The software also calculated the amount of powder and binder needed for the print.

- Step 3: The 3D printer was prepared for the print. The print bed was filled with a fine powder that resembled sandstone, and the inkjet print heads were loaded with the binder that contained color pigments. The print bed was leveled and heated to ensure a smooth and even print.

- Step 4: The 3D printing process was started. The print heads moved over the print bed and selectively jetted the binder over the powder, which caused the powder to solidify and adhere to the previous layer. The process was repeated until the model was complete. The print time depended on the size and complexity of the model, but it usually took a few hours to finish.

- Step 5: The 3D printed model was removed from the print bed and cleaned. The excess powder was gently brushed off and vacuumed away, leaving the model intact. The model was then sprayed with oil and cured in an oven or under a UV light to strengthen the binder and enhance the colors. The model was then ready to use or display.