- SLA 3D Printed Teeth Models with Tough Resin

- SLA 3D Printed Medals for IPO Remembrance with Electroforming Technique

Gallery

About Project

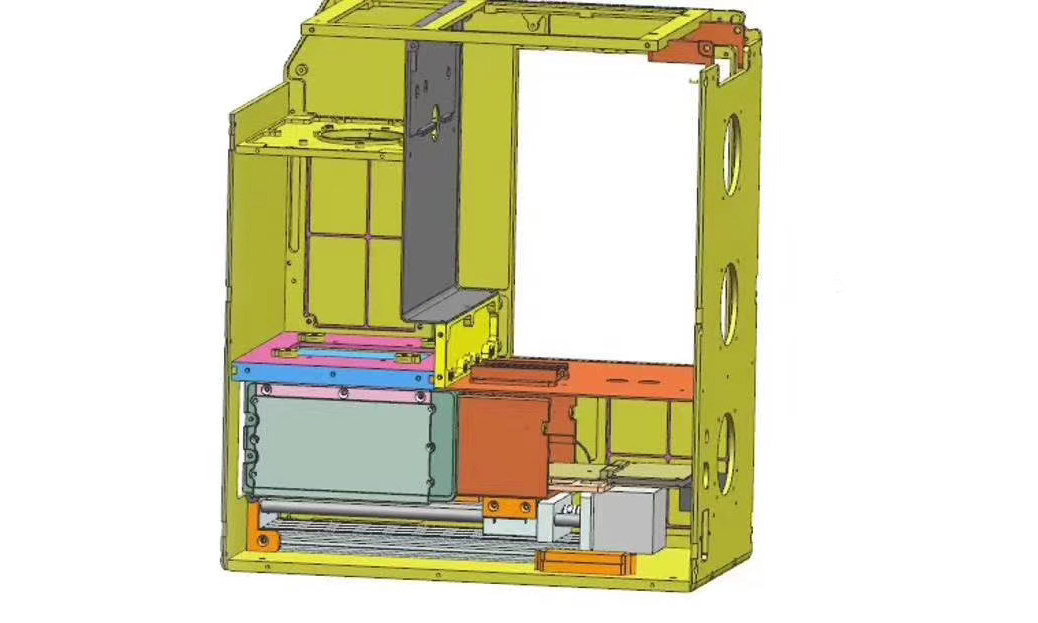

Housings and enclosures for components such as medical devices, industrial apparatus and consumer electronic housings like key fobs, have integral manufacturing requirements. Most need to be void-free, strong, air or water-tight, and often highly cosmetic. Some require materials compatible with medical imaging, electro-static dissipation or electromagnetic shielding.

Beijing Institute of Technology cooperated with Academy of Military Medical Sciences to develop advanced automatic medical equipment. During the R&D process, 3D printing and CNC machining are often applied to build the enclosure.

The build volume of FacFox's large-format SLA 3D printing is 244*800*800 mm, and the build area of our large-format FDM 3D printer is 300*700mm.

Solution

- Step 1: Examine the 3D models and list all the requirements after communication. The model is not simply a hollowed-out enclosure but has a movable drawer. Also, the client plans to put the integrated electric components inside, so we print all the inner components of the enclosure.

- Step 2: 3D print the enclosure and inner units with SLA 3D printing technology, using ABS-like resin. The tolerances are accurately controlled for assembling.

- Step 3: Clear the prints with IPA to remove excess materials. Polish and paint with appointed color.

- Step 4: Assemble all the parts with screws. Screenprint the logo of Beijing Institute of Technology and Academy of Military Medical Sciences.