- Urethane Cast Magical Girl Design Toy with ABS-like Resin

- SLA 3D Printed and Screen-printed Test Tube Rack Prototype

Material Resin, Metal

Quantity 1 pcs

Price Range $1,000-5,000

Lead Time 5 workdays

Gallery

About Project

A young lady felt painful and found she had a tumor in her chest cavity after a medical examination.

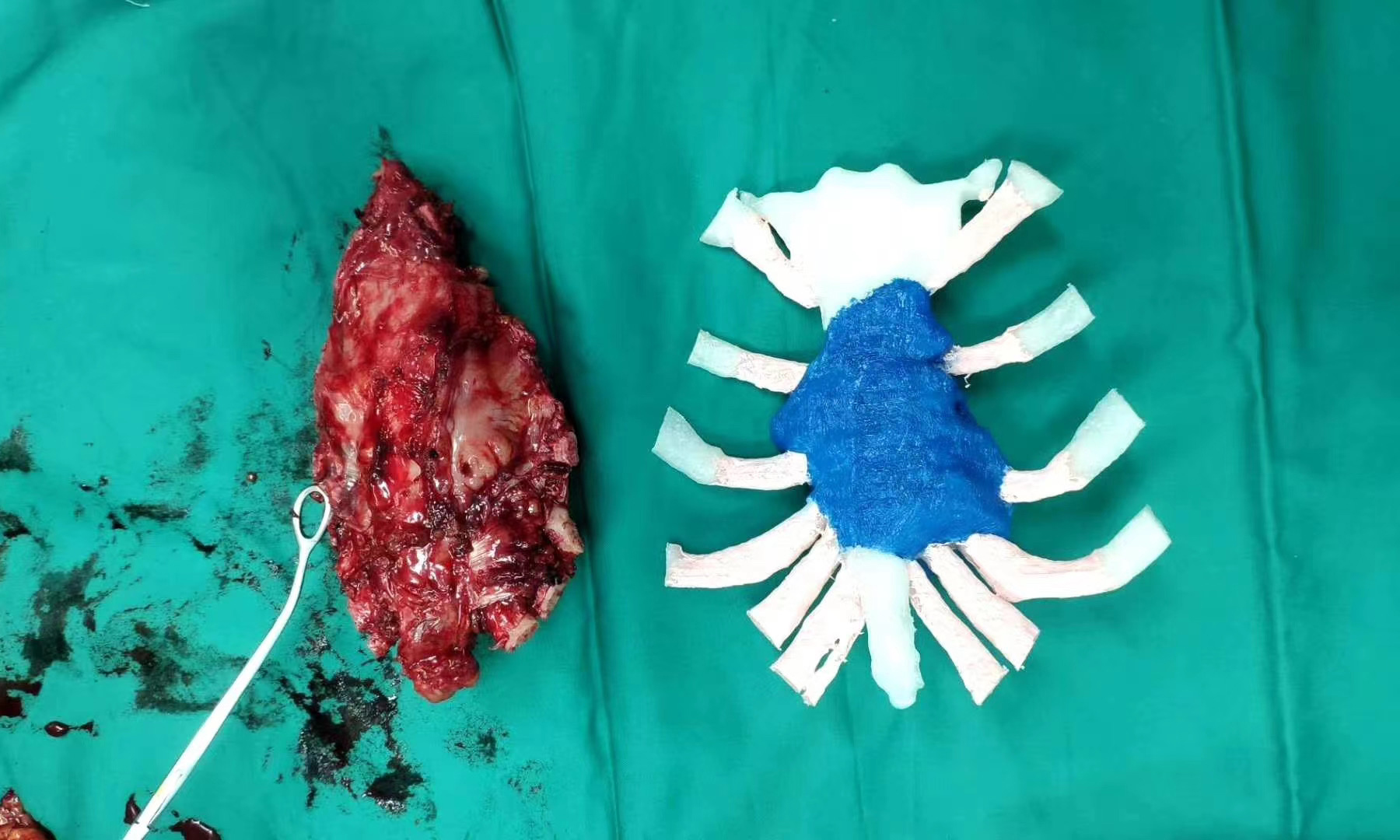

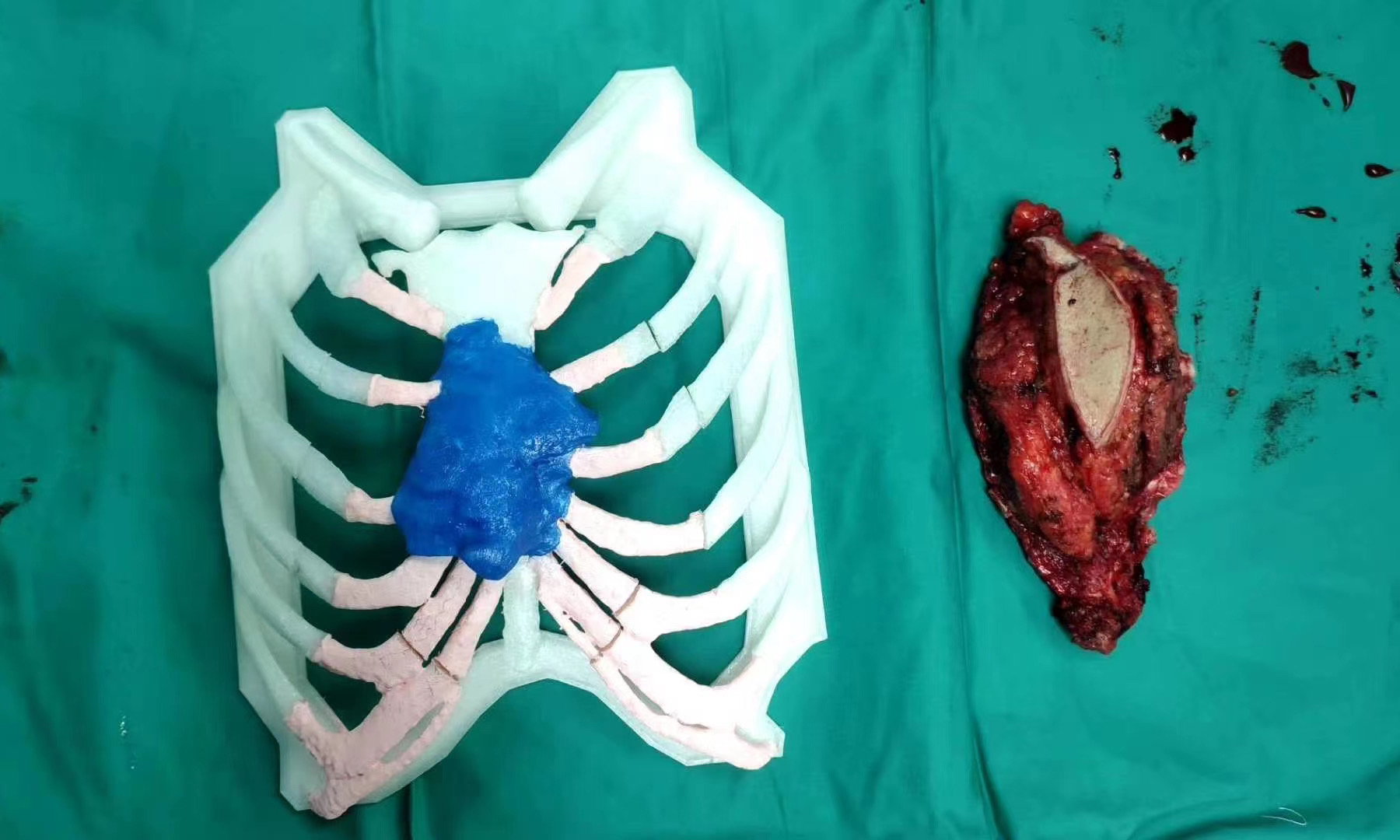

Known as a sarcoma, this type of cancer occurs in bone, cartilage, fat, muscle, vascular, or hematopoietic tissues. In this case, the patient had a sarcoma in their chest cavities and had to have their sternum and parts of their ribcage removed. This presented numerous surgical challenges, as this area of the chest has complicated geometries that are notoriously difficult to recreate with prosthetics.

Doctors believed they could perform surgery to remove it, but the procedure would be intricate because of the bone and tissue surrounding the area that would also need to be removed. Therefore, a surgical guide is necessary. We build the 3D model of her breastbone together with the to-be-replaced sternum area.

We also printed a custom-made metal chest implant with titanium. The customizable implant can be adjusted to fit into the affected area and then secured in place with screws.

Solution

- Step 1: The patient is required to undergo a 64-row enhanced chest CT scan (GE Lightspeed VCT) before surgery, with a thickness of 1.0 mm. Import the chest CT data in DICOM format into Mimics software for model construction; further import the generated STL file into Geomagic Studio software for pre-planning.

- Step 2: Produce the chest model with SLA 3D printing technology using SLA Generic Resin. The UV-cured resin prints can display fine details, sharp edges and a smooth finish.

- Step 3: The design plan of the 3D printed implants was jointly formulated by the surgeon and our engineers. All implants were designed based on the patient’s original sternum structure, and at the same time fully considered the boundary principle of tumor resection and the principle of no tumor. The tumor resection boundary is more than 3 cm from the edge of the tumor.

- Step 3: Import the STL format file of the above design into the DMLS 3D printer for implant production. The printer uses medical-grade titanium alloy powder and uses laser sintering technology to make implants. The implant is used in surgery after cleaning, high-temperature and high-pressure sterilization.