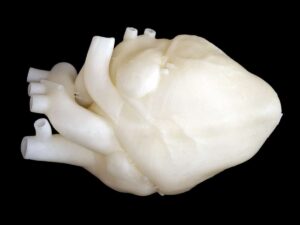

3D Printed Brain Models with SLA Clear Resin, PolyJet Rubber and DLP Silicone

- SLA 3D Printed Transparent Shiba Inu Dog Statue with Clear Resin

- SLA 3D Printed Resin Helmet with Clear Black Face Guard for a Fashion Designer

Posted on 2021-07-06 in Medical ┬Ę Õī╗ń¢Ś

Process 3D Print, 3D Print, Support Removal, Post Curing

Material Resin, Other

Quantity 3 pcs

Price Range $1-100

Lead Time 5 workdays

Material Resin, Other

Quantity 3 pcs

Price Range $1-100

Lead Time 5 workdays

Gallery

About Project

In this case, we produce the same brain model using different materials and technologies. The left one is printed yellow silicone with DLP technology. It touches soft and has high elasticity. The middle one is printed with PolyJet Rubber, which looks translucent and has medium elasticity. The right one is totally transparent, printed with SLA Clear Resin, but has nearly no elasticity.

A common printing challenge is: how to totally remove the supports. It's easier for PolyJet prints to get rid of excess materials as the supports are printed with soluble material.

The silicone DLP 3D printer is being tested now. FacFox will offer the silicone printing service soon!

Solution

- Step 1: Firstly we need to check the model and add supporting structures. The supports are required to prop up the gyrus and sulcus structure. As the sulcus lay a bit deep, it is kinda difficult to fully remove the supports.

- Step 2: Typically silicone parts are produced through a casting process, where molds are printed and then filled with liquid silicone to form the parts. We employ a vat filled with photosensitive liquid silicone. For each layer of the brain model, a UV light source traces the coordinates to be cured. The print bed moves one layer in the Z direction, allowing for a new liquid layer to be prepared for tracing.

After the silicone print has been removed from the printer, it is usually subject to a longer post-curing process, for example in an oven, which causes further chemical reactions within the silicone part and removes unwanted particles. Parts may also need to be washed to remove support material. - Step 3: PolyJet 3D printing is similar to inkjet document printing. But instead of jetting drops of ink onto paper, PolyJet 3D printers jet layers of liquid photopolymer onto a build tray and cure them with UV light. The layers build up one at a time to create a 3D model or prototype. Fully cured models can be handled and used immediately, without additional post-curing.

Along with the selected model materials, the 3D printer also jets a gel-like support material specially designed to uphold overhangs and complicated geometries. It is easily removed by hand and with water. - Step 4: SLA 3D printing process is quite alike to the DLP printing process. The laser ŌĆ£drawsŌĆØ the first layer of the print into the photosensitive silicone. Wherever the laser hits, the liquid solidifies. The process is repeated until the whole part is complete. After finishing the material polymerization, the platform rises out of the tank and the excess silicone is drained. At the end of the process, the model is removed from the platform, washed of excess silicone, and then placed in a UV oven for final curing.