SLA 3D Printed Resin Helmet with Clear Black Face Guard for a Fashion Designer

- 3D Printed Brain Models with SLA Clear Resin, PolyJet Rubber and DLP Silicone

- SLS 3D Printed and Painted Piranha Mouse Cover Kit

Posted on 2021-07-05 in Fashion ┬Ę µŚČÕ░Ü

Process 3D Print, Support Removal, Post Curing, Primer Coating, Polish, Paint, Water Transfer Printing

Material Resin

Quantity 10 pcs

Price Range $1,000-5,000

Lead Time 10 workdays

Material Resin

Quantity 10 pcs

Price Range $1,000-5,000

Lead Time 10 workdays

Gallery

About Project

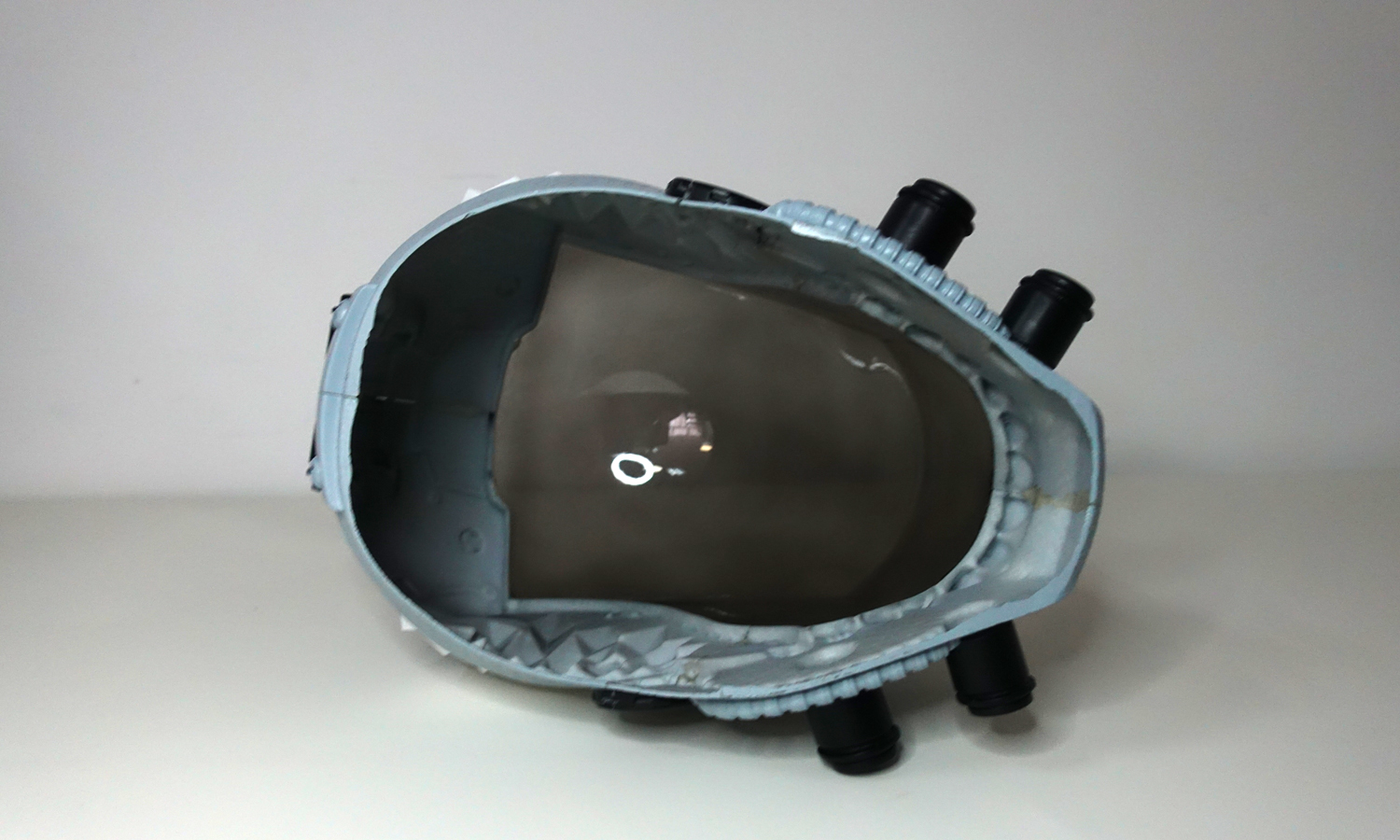

This helmet, named GRIT, is designed by a fashion brand 404040.club. It could not be used for motorcycle riding, nor can it protect us from hazards. It's really sick for young people who want to dress outstandingly. And that's enough.

The designer ordered a batch of ten helmets, all in the same size to fit your head.

Solution

- Step 1: As the client is not sure about the dimension, he firstly orders one helmet and scales up the size to 113%. As the clear visor and the rest parts are in different materials, our engineer splits the 3D model and adds supports, then arranges the placement of all pieces.

- Step 2: 3D print the visor using SLA Clear Resin with our industrial SLA 3D printer. The green part needs to go through common post-process like supports removal, IPA washing, sanding, and polishing. Then we spray it with thick UV oil to make it as clear as possible, and cover it with a thin layer of black clear paint.

- Step 3: The enclosure is printed with SLA ABS-like Resin. As the client wants to save the shipment cost, we split the enclosure into four parts. After the common post-process, we spray with putty and paint the corresponding parts with black, grey, and white colors.

- Step 4: Assemble the helmet into one piece. As this one is just printed as a test, we do not glue it carefully. We try to wear it but it’s still not large enough. The designer then enlarges it to 120% and orders 9 pieces. The amount is still small, so it’s not economical to make them with injection molding technology. All ten helmets cost less than $4000.