- Daily FacFox: January 03, 2020 at 09:00PM

- SLA 3D Printed Saltwater Fishing Lure Prototypes with Vacuum Plating

Gallery

About Project

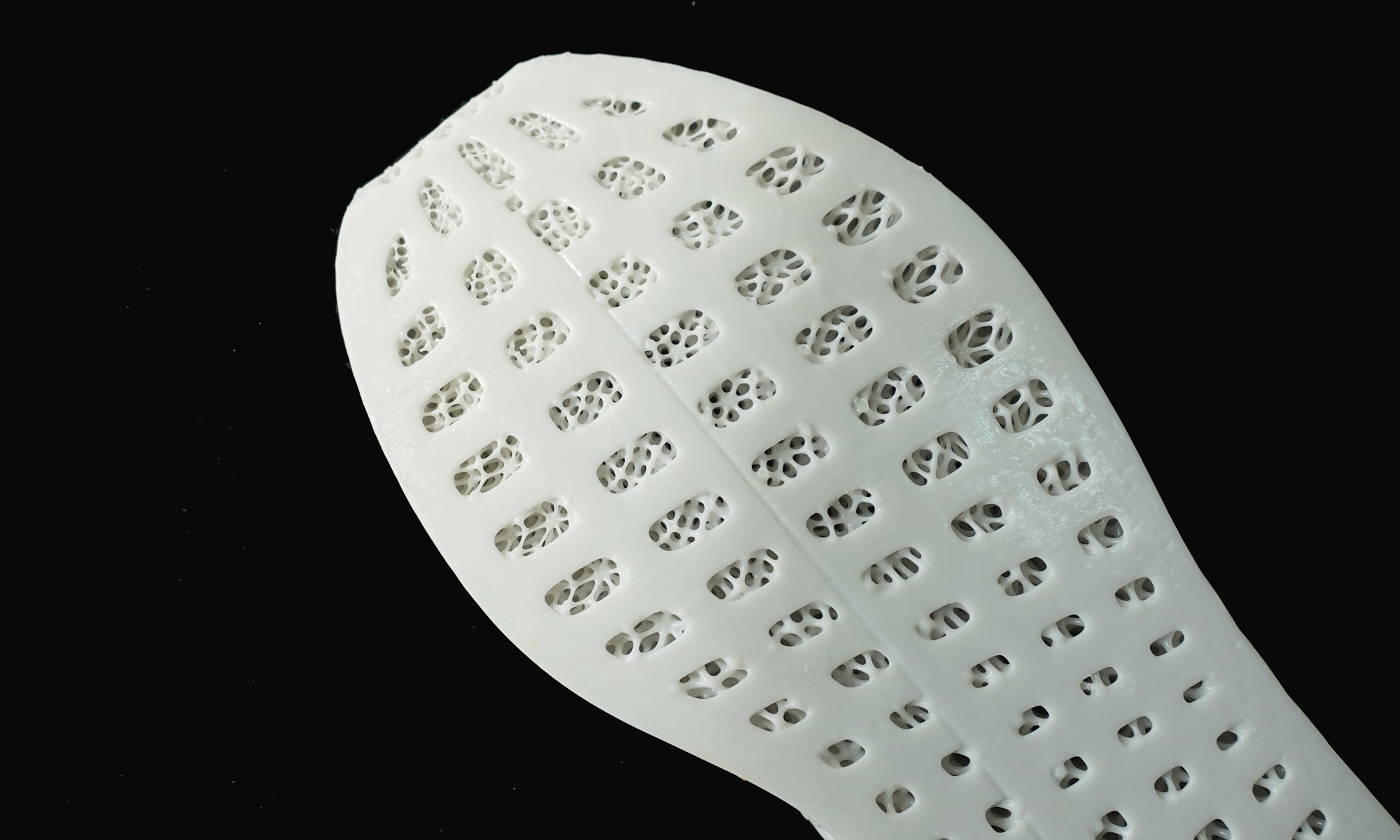

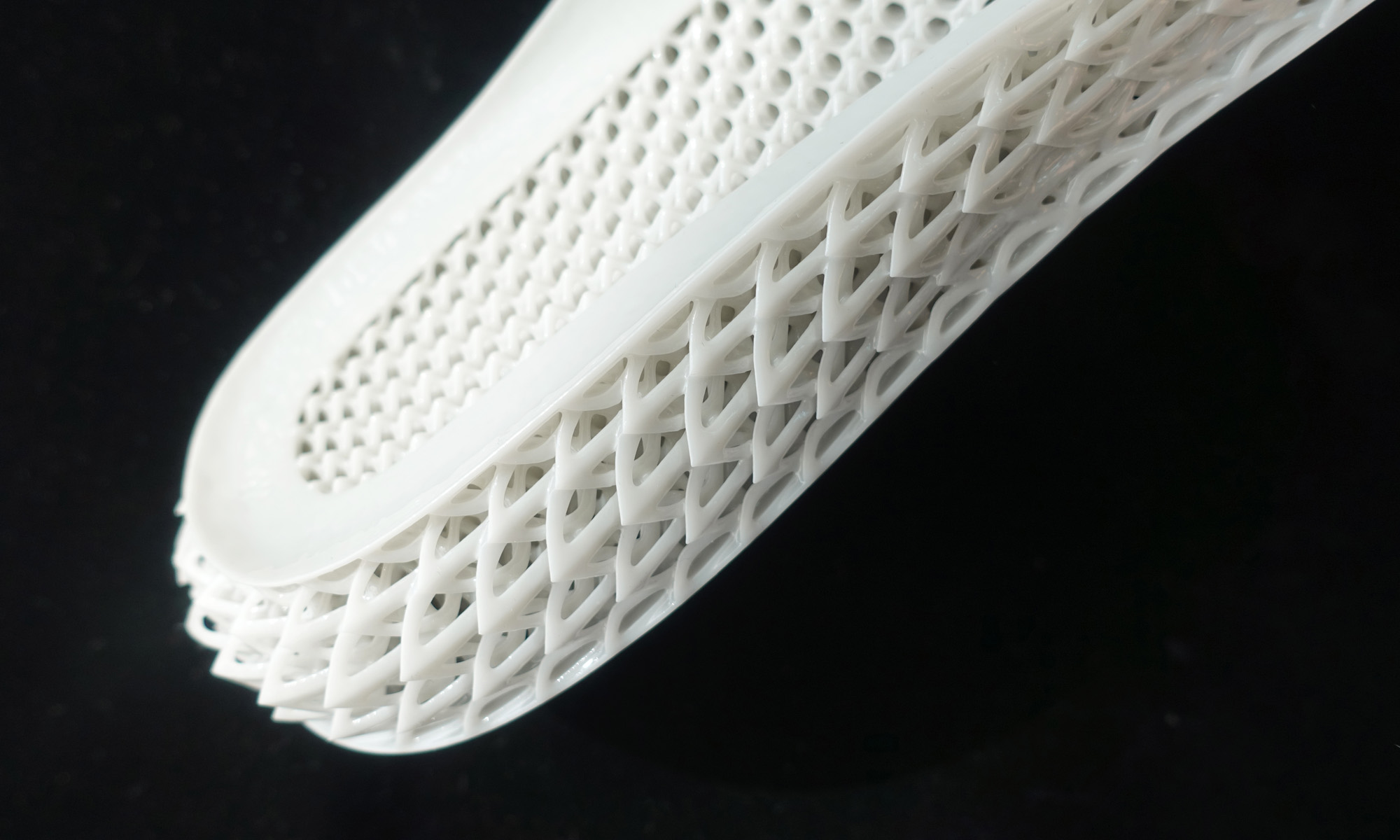

FacFox offers services from low-volume customization to mass production of running shoe midsoles. We can print one pair of shoes vertically in 2 hours, and print horizontally in 20-30 minutes.

This technology is based on light-curing DLP technology. In simple terms, it is to project light of a specific intensity onto a liquid photosensitive resin, so that the latter is cured and formed layer by layer.

Our newly published rapid light curing technology can cure one layer at a time, with higher accuracy. After each layer is printed, the molding plate ŌĆ£adheringŌĆØ to the printed product rises, and then the light continues to cure the next layer, cycling back and forth. With the increase of the solidified part, the object gradually ŌĆ£exposed to the water surfaceŌĆØ, it looks like the molding table ŌĆ£pumpsŌĆØ the object from the liquid.

Solution

- Step 1: 3D scan the feet of our customers and import the statistics into our specially developed software to generate the 3D model.

- Step 2: Add supporting structure onto the model in the slicing software, then export it to the DLP 3D printers.

- Step 3: 3D print the midsoles with simplified and advanced DLP technology, which can achieve high printing speeds and production part performance, and make customized volume production possible.

- Step 4: Wash off the supporting structure and post-cure them with UV.