- DLP 3D Printed Silicone Rubber U-shaped Toothbrush Shore 25A Failed Case

- MJF 3D Printed Full-color HP Nylon RPG Minis Custom Statue for Board Game

Gallery

About Project

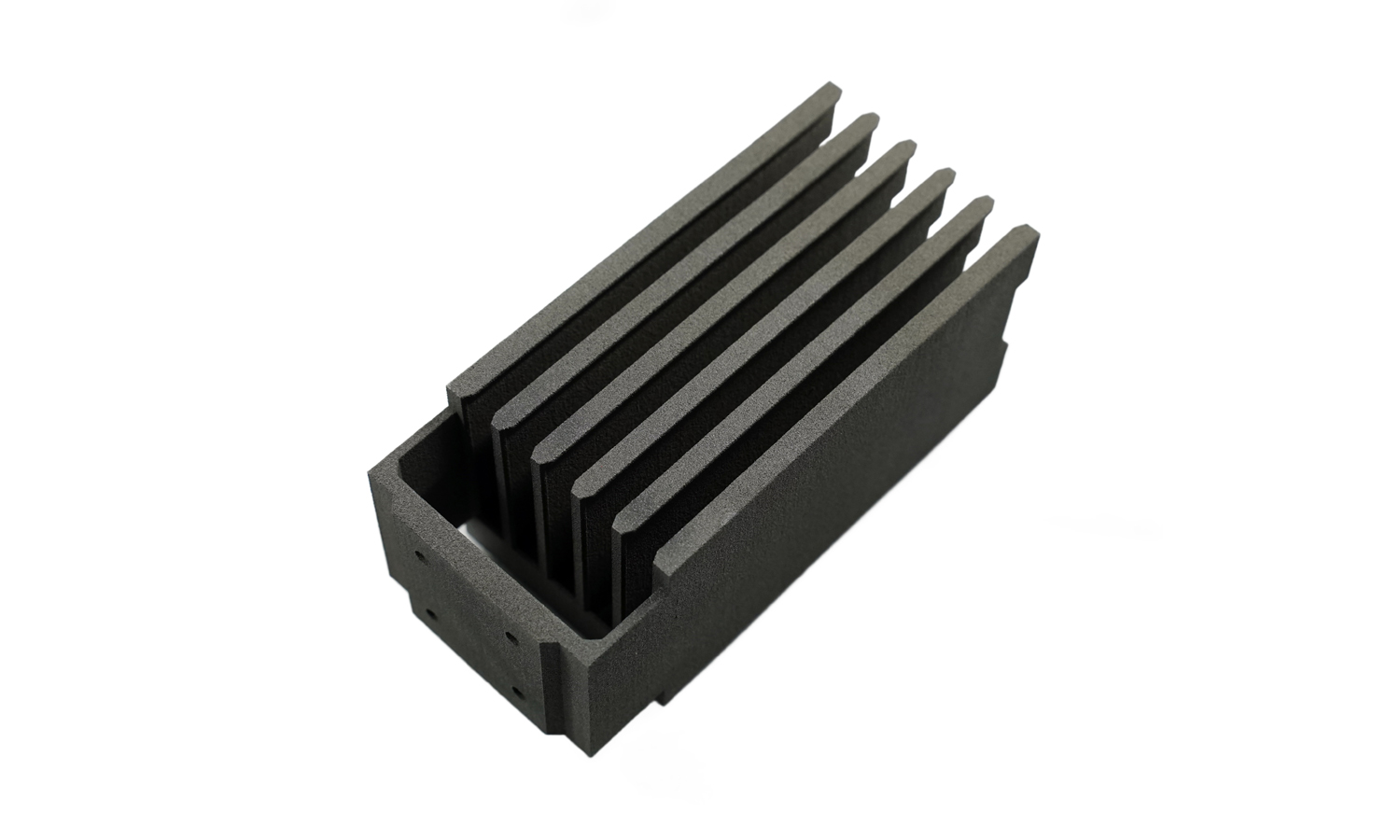

If you are looking for a way to create custom heat sinks for your electronic devices, you should consider nylon printing service from FacFox. FacFox is a leading online platform that provides fast and reliable 3D printing solutions for various industries.

The nylon printing service from FacFox uses SLS 3D printing technology and PA12 material to produce high-quality heat sink prototypes. SLS stands for selective laser sintering, a 3D printing process that uses a laser to fuse nylon-based powder into solid parts. Nylon PA12 is a type of nylon material that offers high strength, stiffness, and resistance to heat and chemicals.

To get your nylon prototypes from FacFox, you just need to upload your 3D model, choose your material and finish options, get an instant quote, and receive your parts within one week!

Solution

- Step 1: First, the 3D model would be broken down into layers of 0.1 mm on the computer and sent to the 3D printer.

- Step 2: Before printing, the tank would be filled with SLS Grey Nylon PA12 powders. On a bed pressure, a 0.1 mm thick layer over the whole width was applied.

- Step 3: The machine was preheated to above 100┬░C, and the laser would light the powder and increase the temperature just above the melting point of the powders.

- Step 4: After a layer was formed, the platform would lower down and produce another layer until the whole model got produced.

- Step 5: When the printing process ended, excess powders which also served as supports would be removed with brushes and a vacuum cleaner.