- SLA 3D Printed Clear Resin Replica of Ancient Chinese Vase

- FDM 3D Printed Genshin Impact Mora Coin for Chocolate Molding

Material Plastic

Quantity 1 pcs

Price Range $100-1,000

Lead Time 4 workdays

Gallery

About Project

Asymmetrical skull, also known as plagiocephaly or brachycephaly, is a condition that affects some infants due to external forces on their soft skull bones. It can cause cosmetic and functional problems, such as facial asymmetry, ear misalignment, and developmental delays.

One of the most effective treatments for this condition is cranial remolding orthosis, which is a custom-made helmet that gently guides the head growth and corrects the shape as the baby grows. However, traditional helmets are often heavy, bulky, uncomfortable, and expensive.

ThatŌĆÖs why FacFox, a leading online 3D printing service in China, offers a better solution: FDM 3D printed PLA infant cranial remodeling helmet designed from 3D scan.

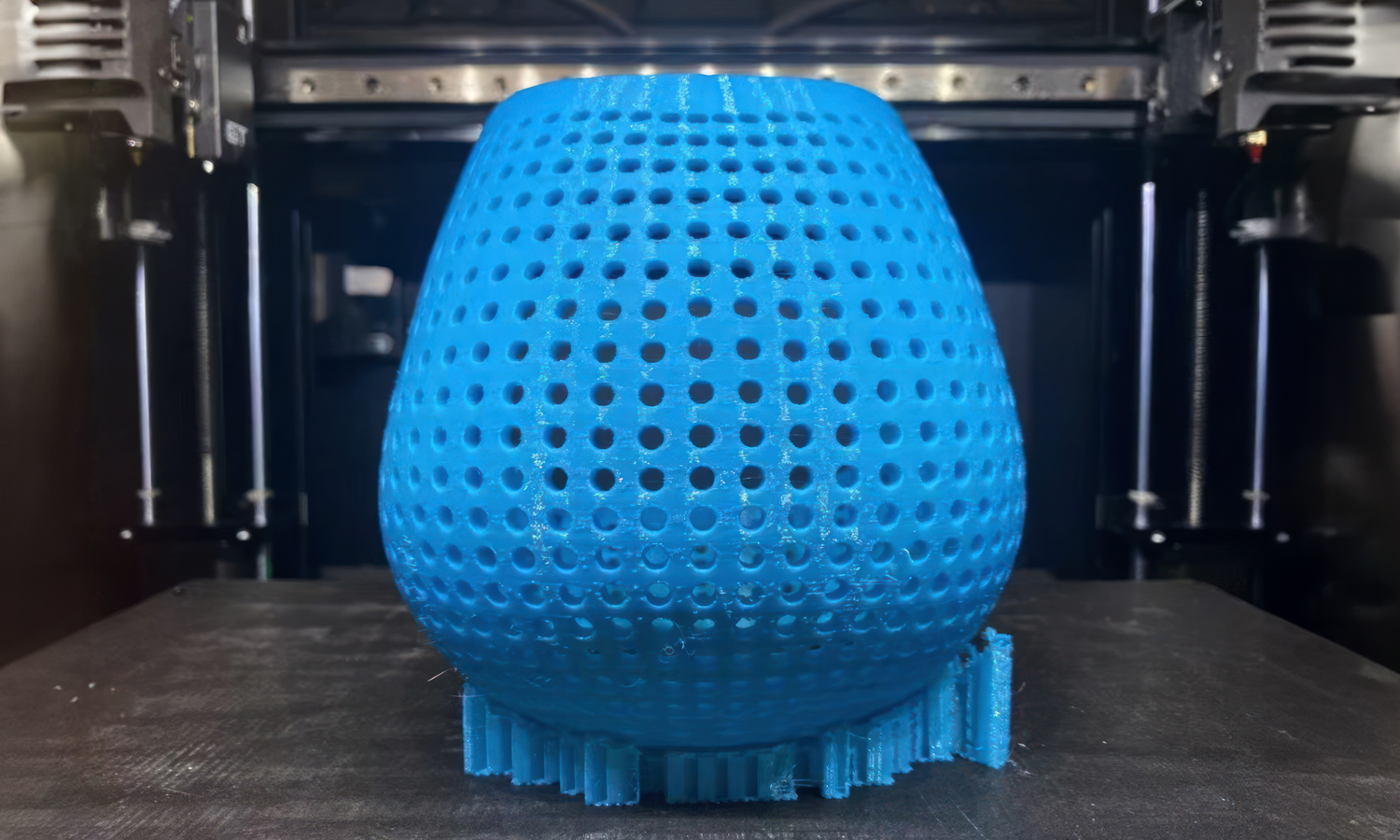

FDM (Fused Deposition Modeling) is a 3D printing process that extrudes molten plastic layer by layer to create a solid object. PLA (Polylactic Acid) is a biodegradable and eco-friendly material that is safe and suitable for medical applications.

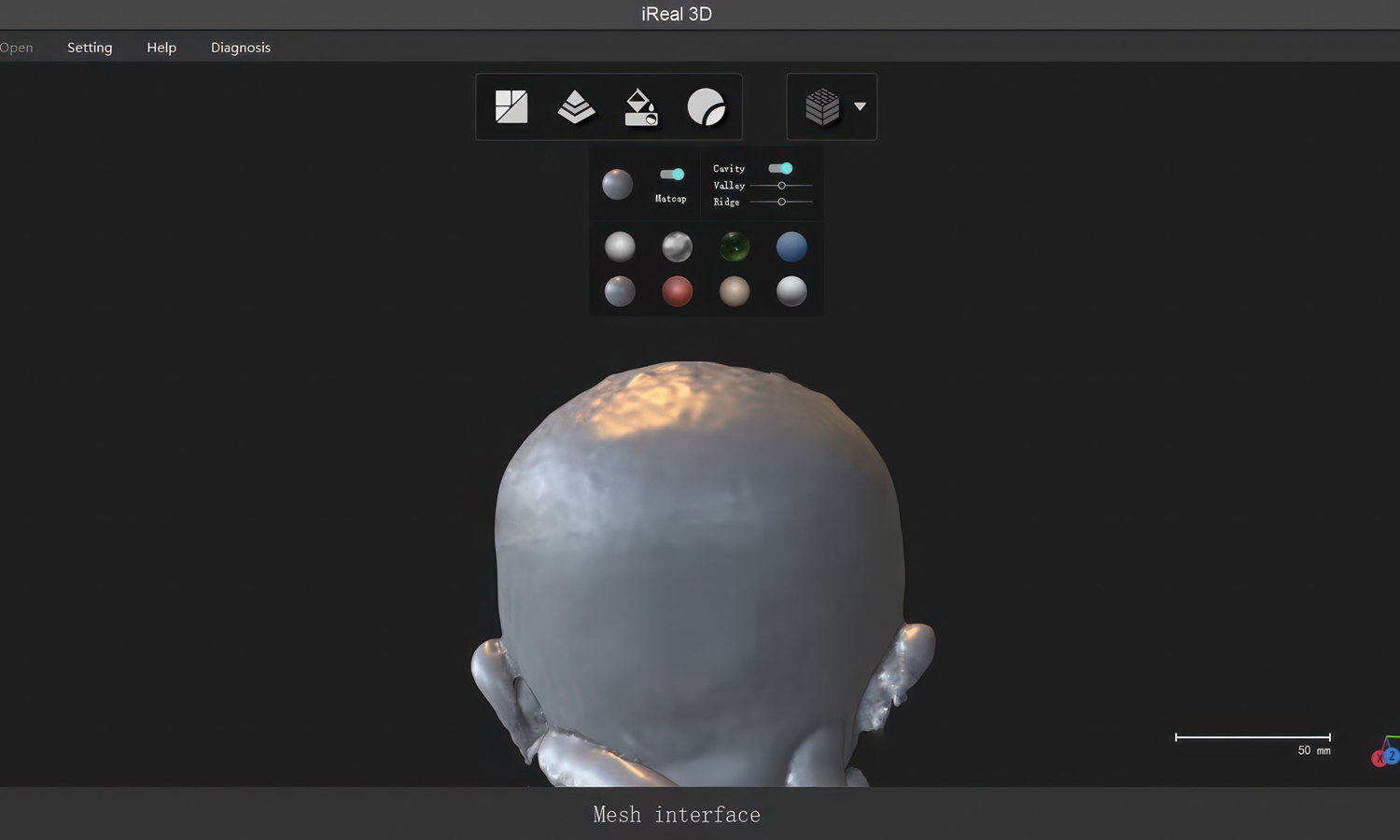

FacFox uses a handheld scanner to collect the data of the infantŌĆÖs head, and then uses software to design a cranial remolding helmet that fits perfectly and comfortably. The helmet is then 3D printed with FDM technology and PLA material, resulting in a lightweight, breathable, and durable device.

The helmet is worn for 23 hours a day, and the treatment duration is typically between 10 to 26 weeks, depending on the severity of the condition and the age of the infant. The helmet is adjusted and replaced periodically as the infant grows and the head shape improves.

FacFox is committed to providing high-quality, low-cost, and fast 3D printing services for various applications, including healing, prototyping, and manufacturing. If you or someone you know needs a cranial remolding helmet or any other 3D-printed product, you can contact FacFox. You can also check their material library to see the wide range of materials they offer, from plastic to metal to rubber.

FacFox is the best partner for your 3D printing needs. Contact us today and see how they can help you realize your creation.

Solution

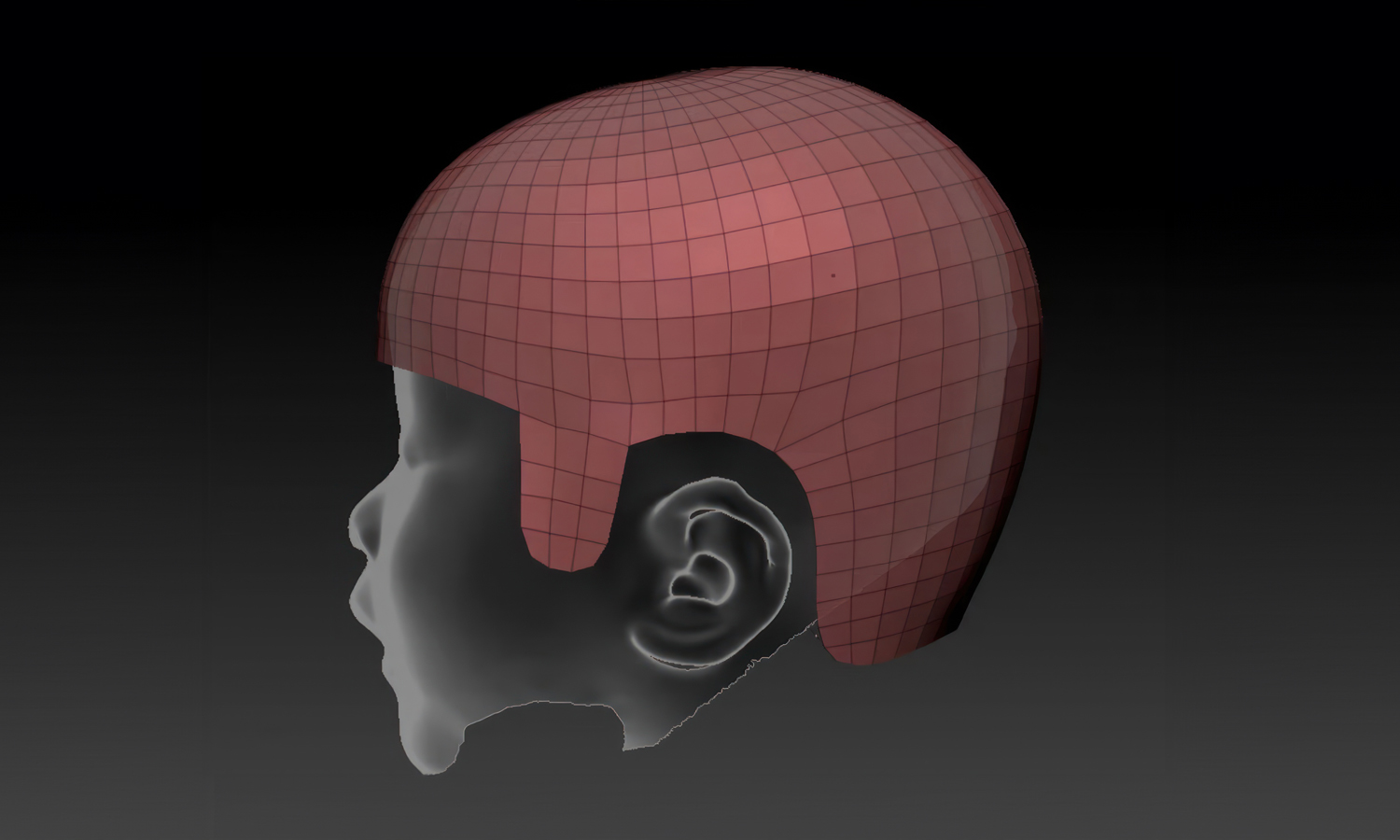

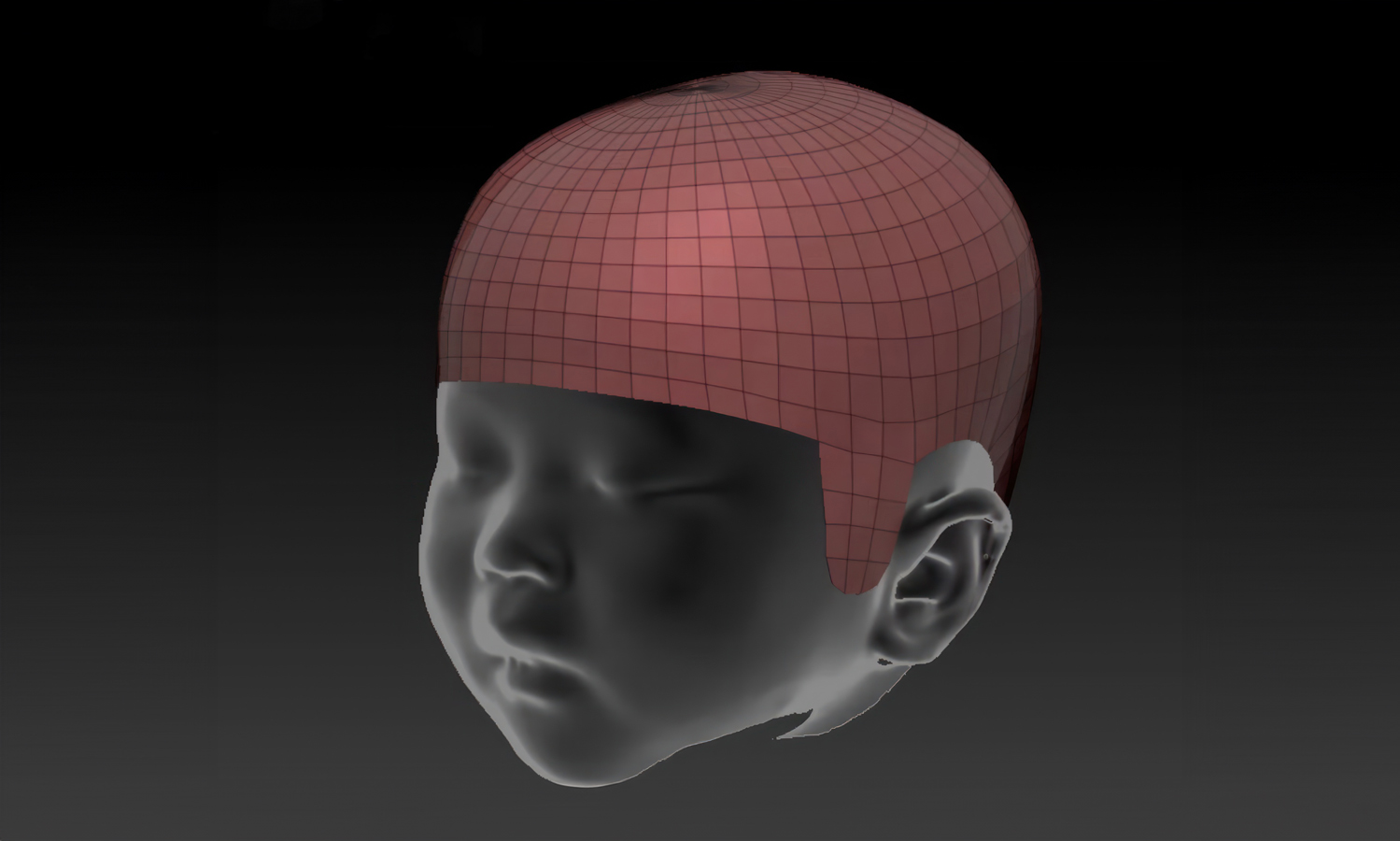

- Step 1: A handheld scanner was used to collect the data of the infantŌĆÖs head. The scanner captured the shape, size, and contours of the skull in high resolution.

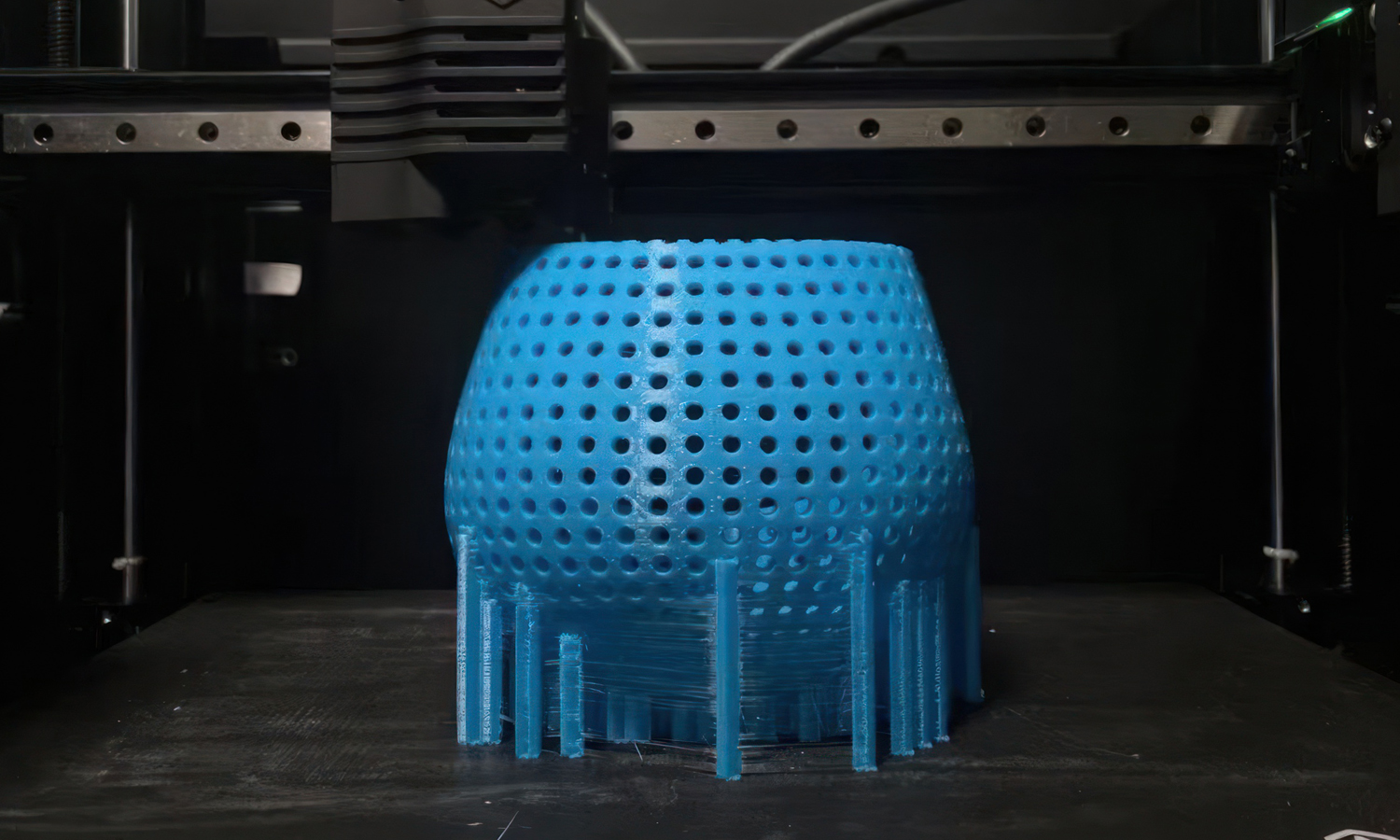

- Step 2: Software was used to design a cranial remolding helmet based on the scan data. The doctor adjusted the helmet shape to fit the infantŌĆÖs head and to correct the asymmetry. The software also optimized the helmet for FDM 3D printing, such as adding support structures and infill patterns.

- Step 3: The helmet design was exported as a 3D model file and sent to an FDM 3D printer. The printer loaded a spool of PLA filament and heated it to a melting point. The printer extruded the molten filament through a nozzle and deposited it layer by layer onto a build platform, following the 3D model instructions. The filament solidified as it cooled down, forming a solid helmet.

- Step 4: The helmet was removed from the build platform and the support structures were detached. The helmet was inspected for quality and accuracy, and then cleaned and polished. The helmet was ready to be worn by the infant.