Gallery

About Project

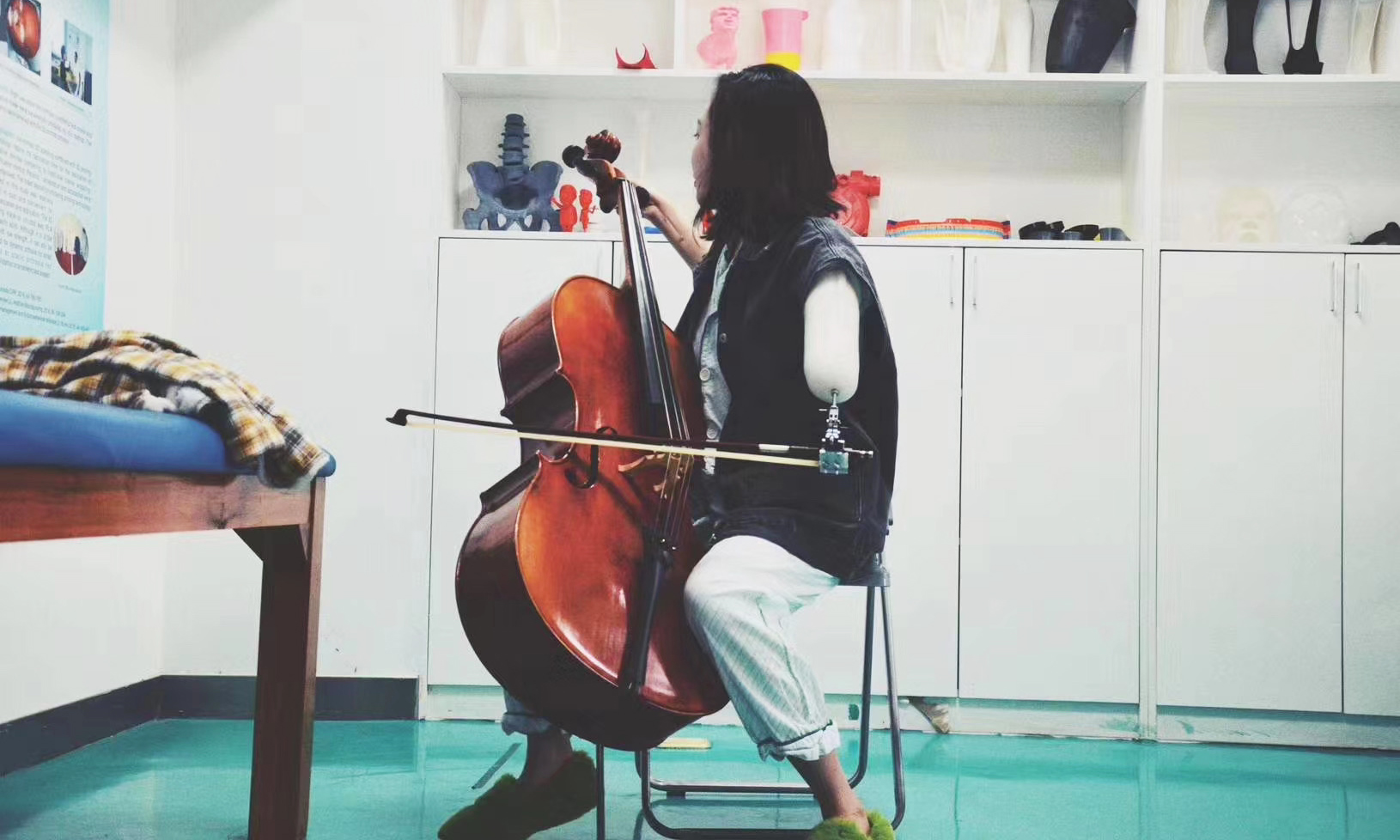

In this case, we accepted an order from a hospital to print the customized functional prosthesis for a viola player who lost her forearm in an accident.

A forearm prosthesis will aim to replace some of the lost function from the missing limb. In general, amputations below the elbow will require simpler devices than those that occur above the elbow. This is because above-the-elbow prostheses require something to act as a substitute for the elbow joint.

The forearm prosthesis is usually composed of these following parts: suspension system, socket, forearm, wrist unit, hand or terminal devices.

The socket, which fits between the prosthesis and the individualŌĆÖs body, is an important element in ensuring that the prosthesis is comfortable and functional. A 3D scanner is applied by the doctor to custom a mould over her stump to ensure an exact fit.

Instead of building an artificial hand, the doctor designed the 3D model of viola bow holder as the terminal devices with reference to Violin TRS Prosthetic, SheaŌĆÖs Viola Bow Holder, and Violin Bow Adapter.

We were hornored to participate in the last process: recommend proper material and techniques, then manufacture the prosthesis. Glad to see the lady played the viola smoothly wearing her prosthesis.

Solution

- Step 1: Examine the 3D model of the prosthesis and recommend making the shell with PETG. PETG combines the ease of use of PLA filament with the strength and durability of ABS filament, making it a great everyday alternative 3D printing material.

- Step 2: Print the outer shell of the forearm prosthesis with our FDM 3D printer. As for the viola bow holder, we used a 5-axis CNC milling machine.

- Step 3: Post-processing, includes sanding, polishing and coloring the FDM prints.

- Step 4: Assemble all the parts and adjust some details to make it fit with the patient’s arm.