FDM Flashforge PETGFlashforge PETG PETG combines the ease of use of PLA filament with the strength and durability of ABS filament, making it a great everyday alternative 3D printing material. Max Build Size Min Build Size 10 x 10 x 10 mm Default Layer Height 0.2 mm Optional Layer Heights 0.2, 0.25, 0.3, 0.4, 0.5 mm Tolerance ┬▒0.4% (with a lower limit of ┬▒0.4 mm) Up to 68 Ōäā Smooth ŌśģŌśģŌśģ Detail ŌśģŌśģŌśģ Accuracy ŌśģŌśģŌśģ Rigidity ŌśģŌśģŌśģŌśģ Flexibility ŌśģŌśģŌśģŌśģ Available ColorsWhite

, Translucent

Available Post ProcessPaint

Suitable For Functional prototypes and end products, Not Suitable For Complex designs with intricate details, Additional InfoPETG is an abbreviation for Polyethylene Terephthalate (with a glycol modification) which is one of the most common polymers used today. ItŌĆÖs used to make water bottles, food packaging, and countless other common plastic items. As a 3D printing filament, PETG plastic has proven its worth as a durable material that is easy to use. Figuratively speaking, it combines the most useful characteristics of ABS filament (the rigidity and mechanical properties for functional parts) with the ease of printing that PLA filament affords. Kind of a ŌĆ£best of both worldsŌĆØ scenario.

Feature

3D PrinterMaterial Spec Sheet

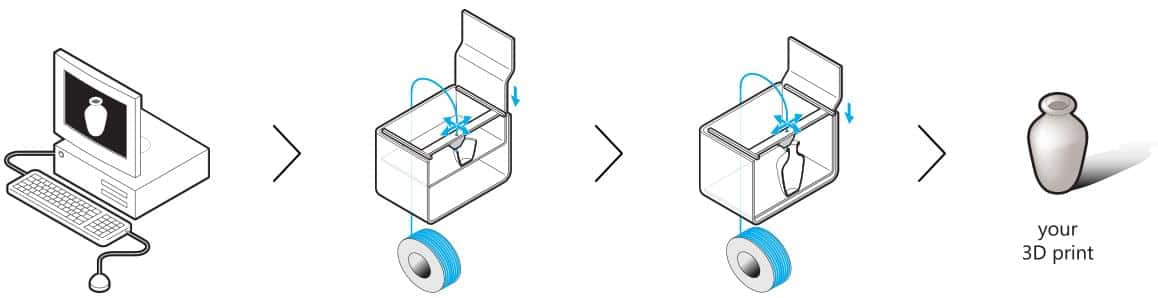

Fused Deposition Modeling is used to build your design with this material. The principle is simple. You can compare it with a hot glue gun into which you put sticks of glue. The glue is heated up until it melts and is then pushed through a fine nozzle in the front of the glue gun. In an FDM printer, a long plastic wire is used in place of glue. It is fed from a spool to the nozzle where the material is liquefied and ŌĆśdrawnŌĆÖ on the platform where it immediately hardens again. The nozzle moves to drop the material at the correct location, drawing your model line by line. When a layer is drawn, the platform lowers by one layer thickness so the printer can start with the next layer. When your model contains overhanging sections, the printer needs to build supporting material. Since the material of the model cannot be deposited in the air, the support material prevents it from falling down. This support material is fed through another nozzle. Afterward, when the model is put into a bath with special soap, the support material dissolves.

|