Gallery

About Project

Chair design, practical or otherwise, is a broad category of objects that seems only to be getting larger. Designers around the world provide constant updates and personal spins, furthering the dialogue about what, and where, we sit upon.

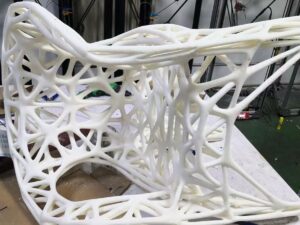

ABS is a common thermoplastic with all-around good mechanical properties, excellent impact strength, good heat resistance, and good maintainability. We recommended using ABS as material to make the dining chair models.

From rapid prototyping to end production, get your parts manufactured with lower cost, higher quality, and faster global delivery. FacFox offers professional manufacturing services including 3D printing, CNC machining, injection molding, urethane casting, metal casting, and more. You could find what you need at FacFox.

Solution

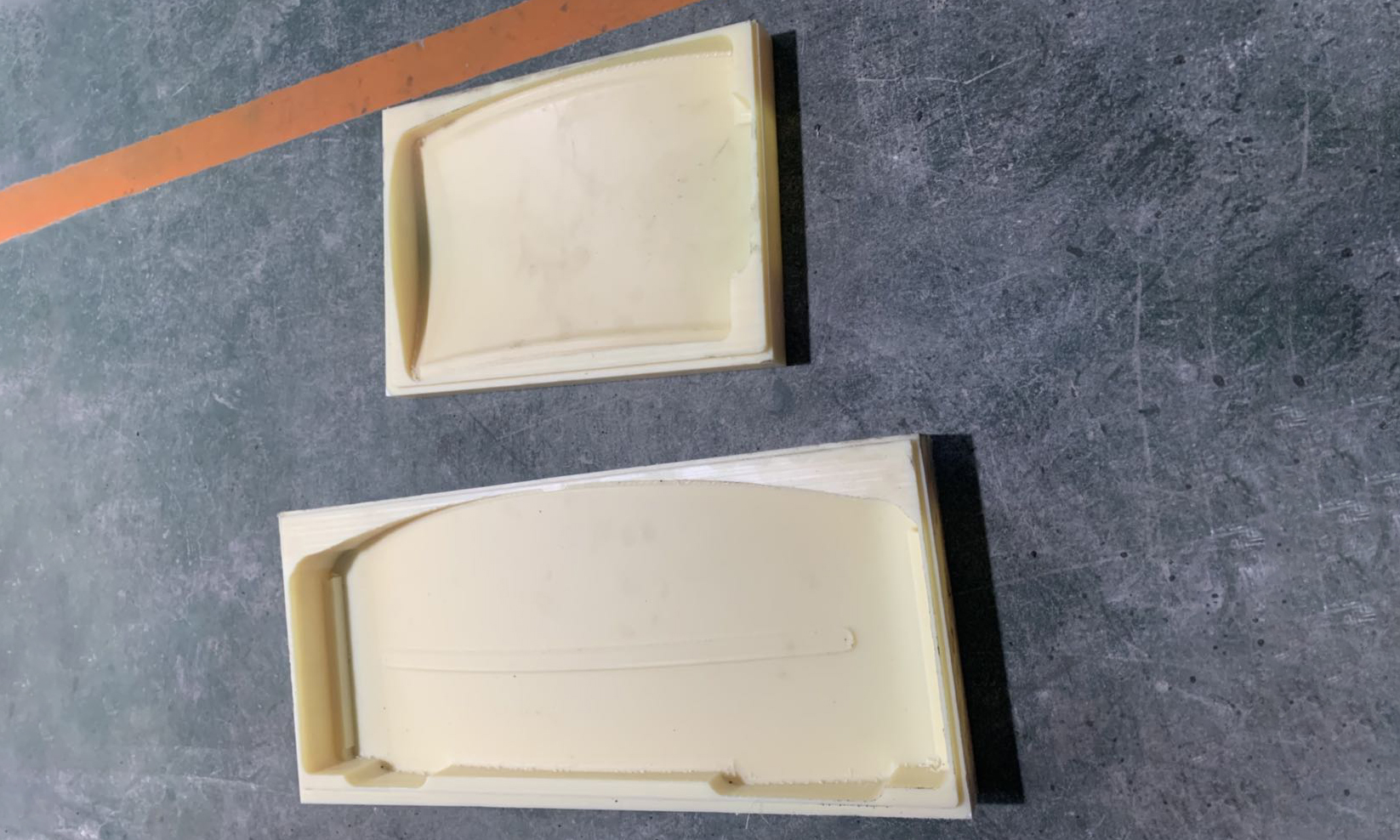

- Step 1: Examined the CAD model sent by our client and input it into CAM software, which converted the CAD file into G-code for the CNC machine.

- Step 2: Our 5-axis CNC machine carries out an automated subtractive manufacturing process, removing material from the ABS boards or blocks to create parts of the chairs, like the seat, back post, apron, legs, spindle, etc.

- Step 3: Cleaned and polished the machined parts with sandpaper, then sprayed with white paint.

- Step 4: Assembled the parts into the dining chair models and temporarily fix them with tape.

- Step 5: Glued the parts together with superglue, then deburred them with blades.