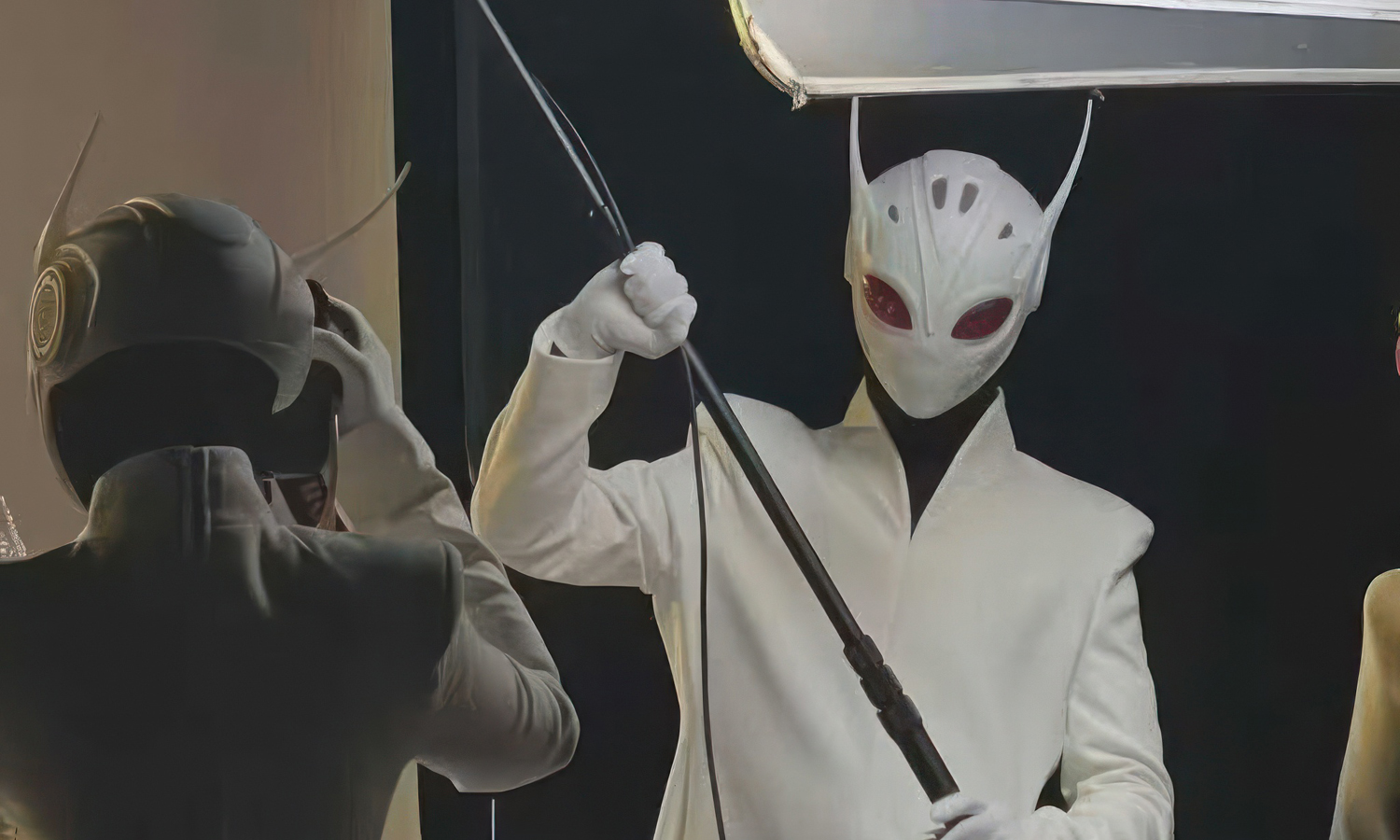

SLA 3D Printed Alien Mask Cosplay Prop

Posted on 2026-01-08 in Fashion ┬Ę µŚČÕ░Ü

Process 3D Print, Support Removal, Post Curing, Polish, Paint

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 5 workdays

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 5 workdays

Gallery

About Project

Check out these incredible, custom-engineered alien masks fresh off the production line. Whether you are building a cinematic universe, upgrading your professional cosplay, or designing high-end props, FacFox is your ultimate partner in bringing complex designs to life.

Why these masks stand out

We utilized high-resolution SLA (Stereolithography) technology to achieve that “injection-molded” finish, followed by expert post-processing to ensure every vent and detail is crisp.

- Intricate Geometry: Notice the ultra-smooth surfaces and the sharp, aerodynamic “antennae” that require precision printing.

- Multi-Material Integration: Designed for a perfect fit with textured honeycomb lenses for that authentic “insectoid” look.

- Lightweight & Durable: Engineered for comfort during long shoots or events without sacrificing structural integrity.

- Scalable Production: Whether you need a single custom prototype or a whole “army” of masks (as seen in our workshop!), we deliver consistent quality.

Bring Your Vision to Life

Stop settling for “off-the-shelf” props. At FacFox, we offer:

- Global Shipping: Fast delivery to your studio or doorstep.

- Expert Consulting: Not sure which material is best? Our engineers are here to help.

- Instant Quotes: Upload your STL/OBJ files and get started today!

Ready to start your next project? ¤öŚ Visit us at FacFox.com ¤ō¦ Contact us: info@facfox.com

Solution

- Step 1: The digital 3D models were meticulously designed in CAD software, where the mask shells and the honeycomb-patterned eyepieces were engineered as separate, interlocking components.

- Step 2: The mask bodies were printed using a high-toughness white photosensitive SLA Generic Resin via SLA (Stereolithography) to ensure a smooth, durable finish.

- Step 3: The eyepieces were simultaneously printed using a transparent photosensitive SLA Clear Resin, allowing the intricate hexagonal honeycomb pattern to be built directly into the geometry of the lens.

- Step 4: Once the printing was finalized, all components were removed from the build plates, and the support structures were carefully stripped away.

- Step 5: The parts were submerged in an isopropyl alcohol (IPA) bath to remove uncured resin, followed by a secondary UV-curing process to stabilize the material properties.

- Step 6: The transparent eyepieces were dyed with a specialized red tint and finished with a clear UV-resistant coating to achieve high-gloss clarity and vibrant color.

- Step 7: The white mask shells were sanded and polished to a matte finish, ensuring all transition lines between the printed layers were completely eliminated.

- Step 8: The red 3D-printed lenses were precisely fitted into the mask sockets and secured, completing the assembly of the final futuristic prop.