Gallery

About Project

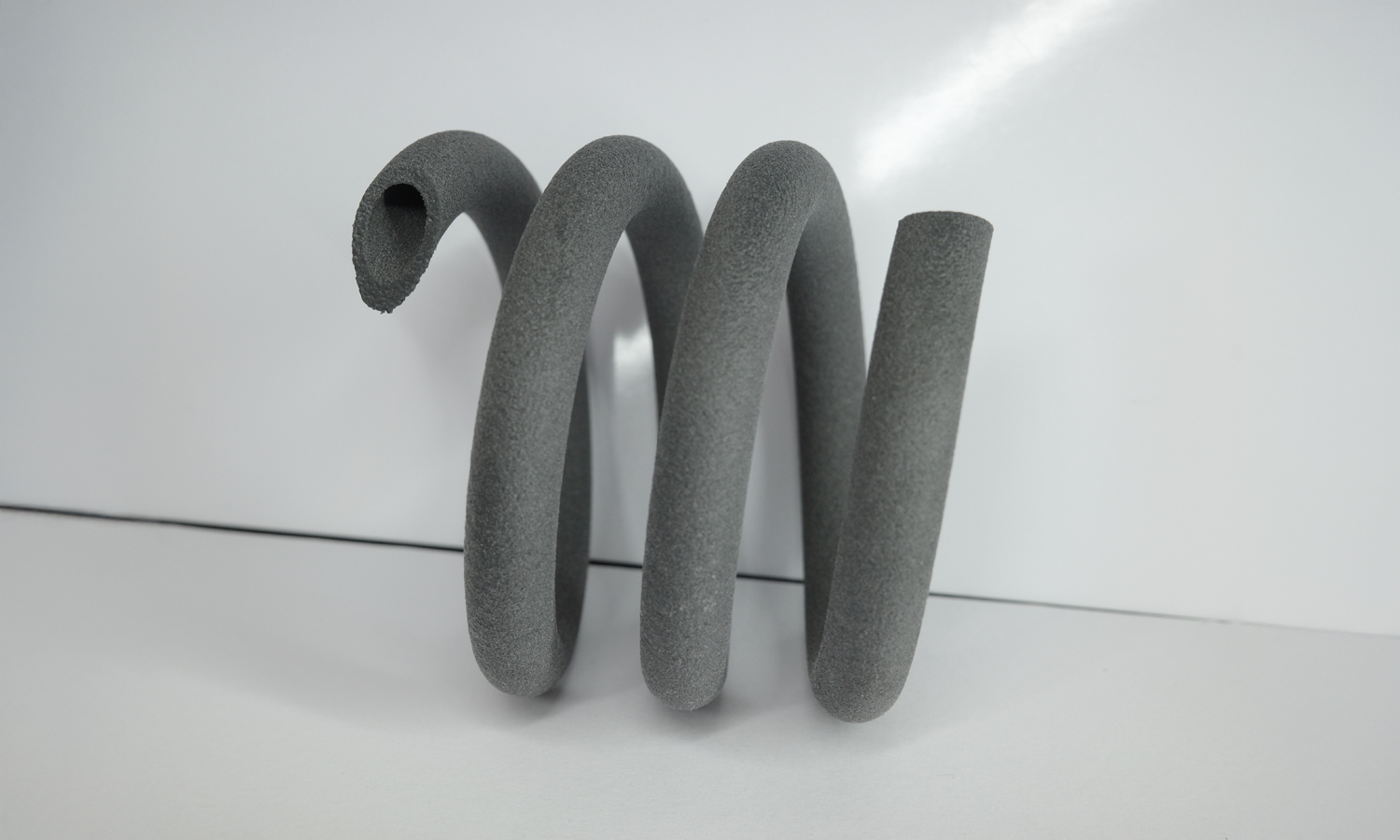

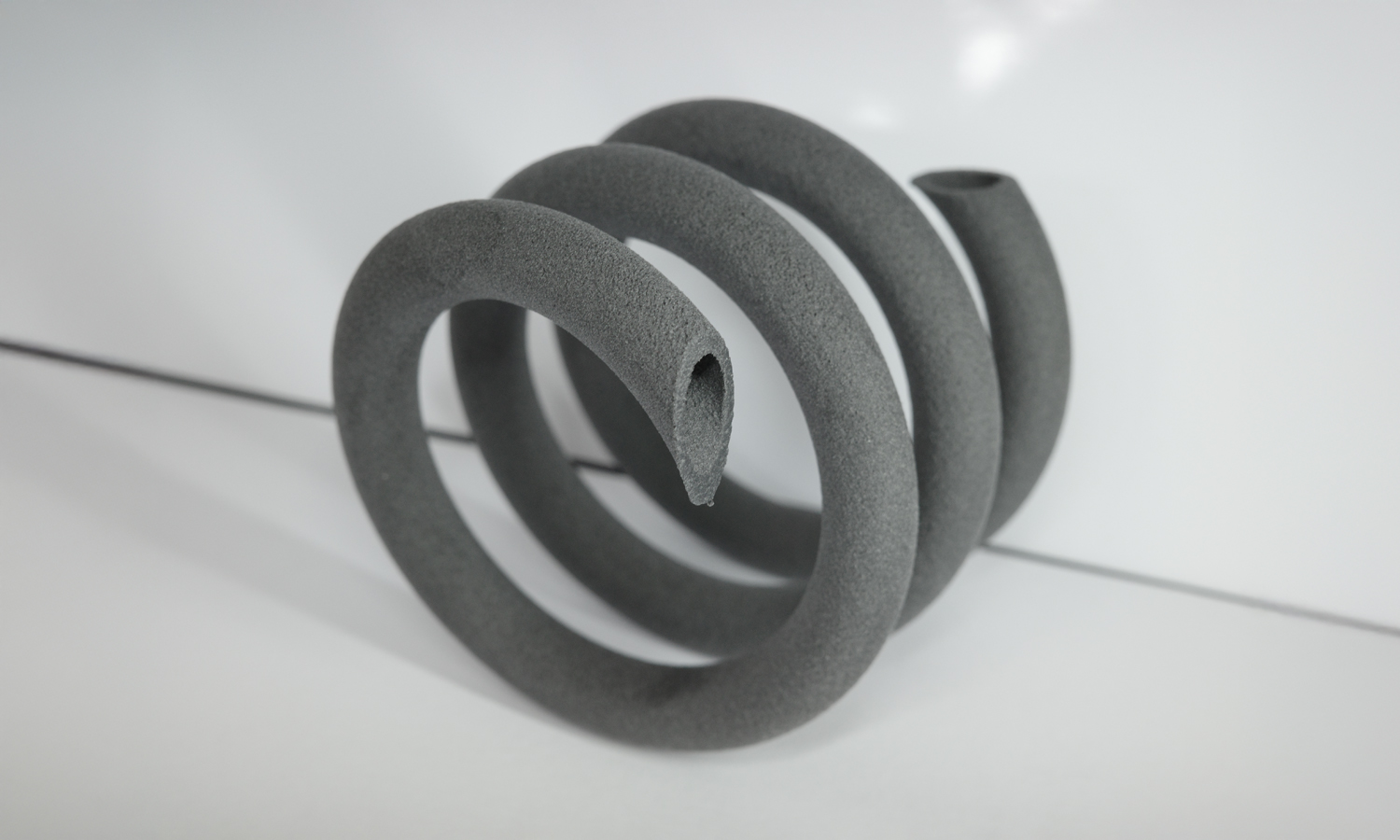

Take a look at this intricately coiled spiral tube, crafted from PA 11 CF using Selective Laser Sintering (SLS) 3D printing. This piece is a testament to the capabilities of SLS technology in creating complex geometries with robust materials.

Structure and Design

The spiral tube showcases a consistent, continuous coil structure, demonstrating the layer-by-layer precision of SLS. The inherent flexibility of PA 11 CF allows the tube to maintain its spiral form while possessing a degree of give, making it suitable for applications requiring both rigidity and flexibility. This type of structure could be utilized in various scenarios, from cable management and fluid transfer to custom mechanical components where a spring-like action is needed.

Surface Quality and Finish

The surface of the tube exhibits the characteristic granular texture of SLS-printed parts. This texture is a result of the unsintered powder particles adhering to the surface during the printing process. While this texture is generally uniform and provides a unique aesthetic, it’s worth noting that the tips on the ends of this particular spiral tube are not very sharp. This is a common occurrence in SLS printing due to the nature of the process and the material’s properties.

Post-Processing Considerations

To achieve sharper edges and a smoother finish, further post-processing is recommended. Sanding the tips would be a straightforward way to refine the edges and achieve the desired sharpness. Additionally, techniques like vapor smoothing or media blasting can be employed to enhance the overall surface quality and reduce the granular texture.

Applications

This type of SLS 3D printed PA 11 CF nylon spiral tube can find applications in various industries, including:

- Robotics: For flexible joints and cable management.

- Automotive: For fluid transfer lines or custom components.

- Consumer Products: For unique designs requiring flexibility and durability.

- Prototyping: For testing form, fit, and function of complex geometries.

Need High-Quality Nylon 3D Printing?

If you’re looking to bring your designs to life with durable and versatile nylon 3D printing, look no further than FacFox. Our state-of-the-art SLS technology and expertise in a wide range of materials, including PA 11 CF nylon, ensure that your projects are executed with precision and quality. Whether you need functional prototypes or end-use parts, FacFox provides reliable and cost-effective 3D printing solutions tailored to your specific needs. Contact us today to get a quote and experience the FacFox difference!

Solution

- Step 1: CAD Model Design. A 3D model of the spiral tube was designed using CAD software.

- Step 2: File Preparation. The CAD model was exported in a suitable file format (e.g., STL) and prepared for 3D printing using slicing software. This involved generating a layered build file that guides the SLS machine.

- Step 3: Powder Bed Preparation. A thin layer of PA 11 CF powder was evenly spread across the build platform within the SLS machine’s chamber.

- Step 4: Selective Laser Sintering. A high-powered laser was precisely directed to trace the spiral tube’s cross-sectional geometry on the powder bed, selectively sintering and fusing the nylon particles together.

- Step 5: Layer by Layer Building. The build platform was lowered, and a new layer of powder was spread on top of the previous layer. The laser then sintered the next layer of the spiral tube, bonding it to the layer below. This process was repeated layer by layer until the entire spiral tube was built.

- Step 6: Cooling and Powder Removal. Once the printing was complete, the build chamber was allowed to cool down. The solidified spiral tube was then carefully extracted from the powder bed, and excess powder was brushed away.

- Step 7: Post-Processing (Optional). As mentioned earlier, the tips of the spiral tube were not very sharp. To address this, the tips were further sanded to achieve the desired sharpness and smoothness.