- SLA 3D Printed Somos Ledo 6060 Impeller Miniature

- Merry Christmas! Wishing you a joyful holiday filled with warmth and inspiration!

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 1 workdays

Gallery

About Project

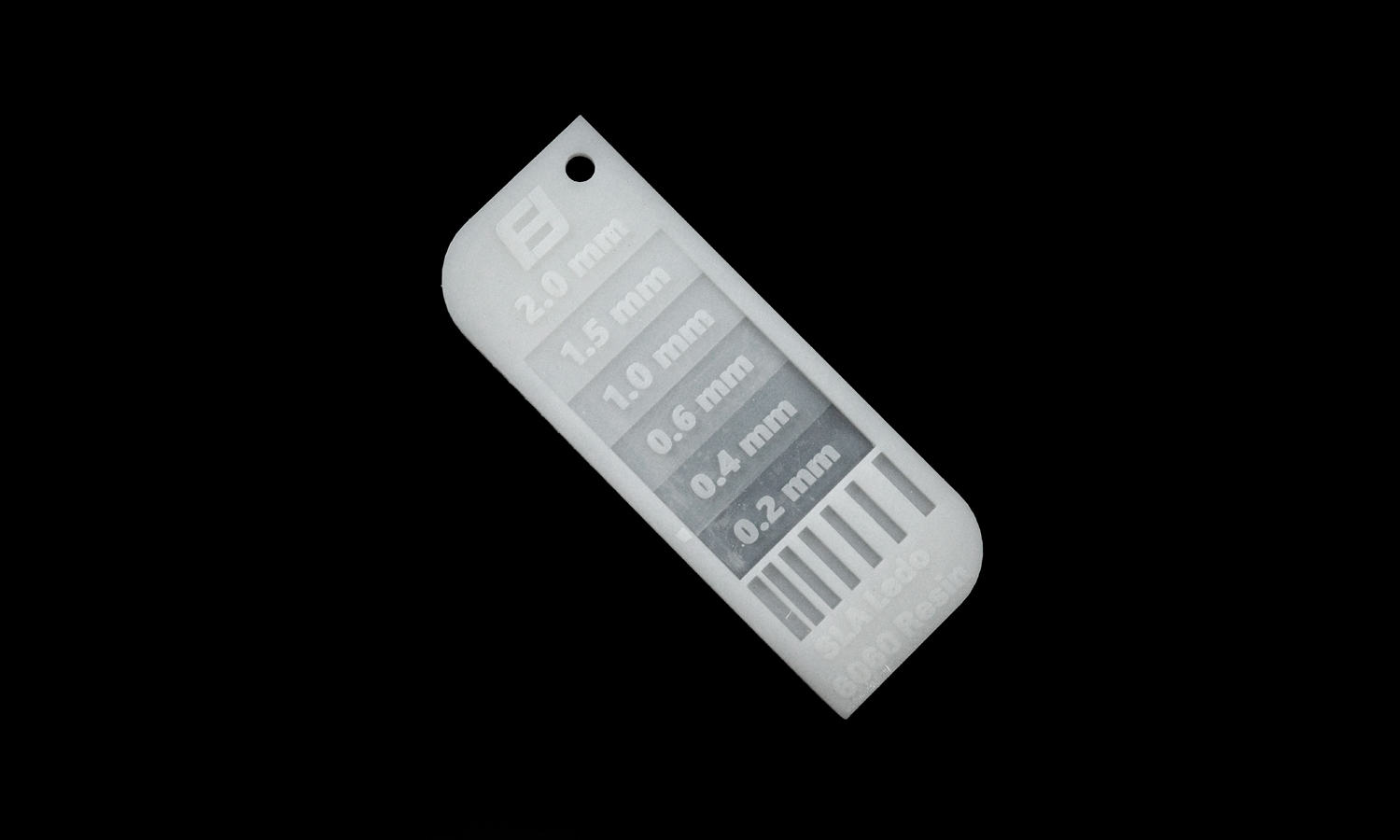

The test model printed using Ledo 6060 resin has successfully captured all the designed details, demonstrating the high precision and quality achievable with this material. Here’s a closer look at the key features and observations:

Features

-

Horizontal Bars with Varying Thicknesses:

- Thicknesses (from top to bottom): 2.0 mm, 1.5 mm, 1.0 mm, 0.6 mm, 0.4 mm, 0.2 mm

- These bars have been printed successfully, showcasing the printer’s ability to handle fine details and varying thicknesses accurately.

-

Vertical Bars of Varying Widths:

- The vertical bars have also been printed with precision, highlighting the printer’s capability to produce consistent and accurate widths.

-

Inscribed Text:

- The text “SLA Ledo 6060 Resin” inscribed at the bottom of the model is clear and well-defined, identifying the material used for this test.

-

Translucency:

- The thinner horizontal bars, ranging from 0.2mm to 0.6mm, exhibit a translucent quality. This is a characteristic of the Ledo 6060 resin when printed in very fine layers.

Overall Printing Quality

- Successful Details: All the designed details, including the various bars, text, and overall geometry, have been printed successfully.

- Translucent Thin Layers: The 0.2mm to 0.6mm thick bars appearing translucent is a testament to the resin’s properties and the printer’s capability to handle such fine layers.

- Support Marks: While there are some support marks left, they can be easily addressed through standard post-processing methods.

Conclusion

The SLA 3D printed test model using Ledo 6060 resin demonstrates excellent precision and detail retention. The successful printing of all designed features, along with the notable translucency of thin layers, highlights the material’s versatility and quality. At FacFox, we specialize in providing top-tier 3D printing services using advanced materials like Ledo 6060 resin. Our state-of-the-art SLA 3D printing technology ensures that every component meets the highest standards of quality and performance. From prototyping to full-scale production, our expert team is dedicated to delivering solutions that exceed your expectations. Elevate your projects with FacFox’s SLA 3D printing services. Contact us today to learn more about our Ledo 6060 resin materials and how we can bring your designs to life!

Solution

- Step 1: The 3D model was sliced into thin layers.

- Step 2: Support structures were generated to ensure proper curing.

- Step 3: The build platform was lowered into a vat of Ledo 6060 resin.

- Step 4: A UV laser beam cured the contours of each layer, solidifying the resin.

- Step 5: The build platform was raised after each layer’s curing.

- Step 6: These steps were repeated until the entire object was built.

- Step 7: The printed part was removed from the build platform.

- Step 8: The part was washed to remove uncured resin.

- Step 9: The part was post-cured with UV light to strengthen the material.

- Step 10: Support structures were removed from the part.