- 3D Printed LCD Tough Black Resin Cable Pass-Through

- SLA 3D Printed Scaled-Down Tactical Truck Resin Model

Material Metal

Quantity 50 pcs

Price Range $100-1,000

Lead Time 4 workdays

Gallery

About Project

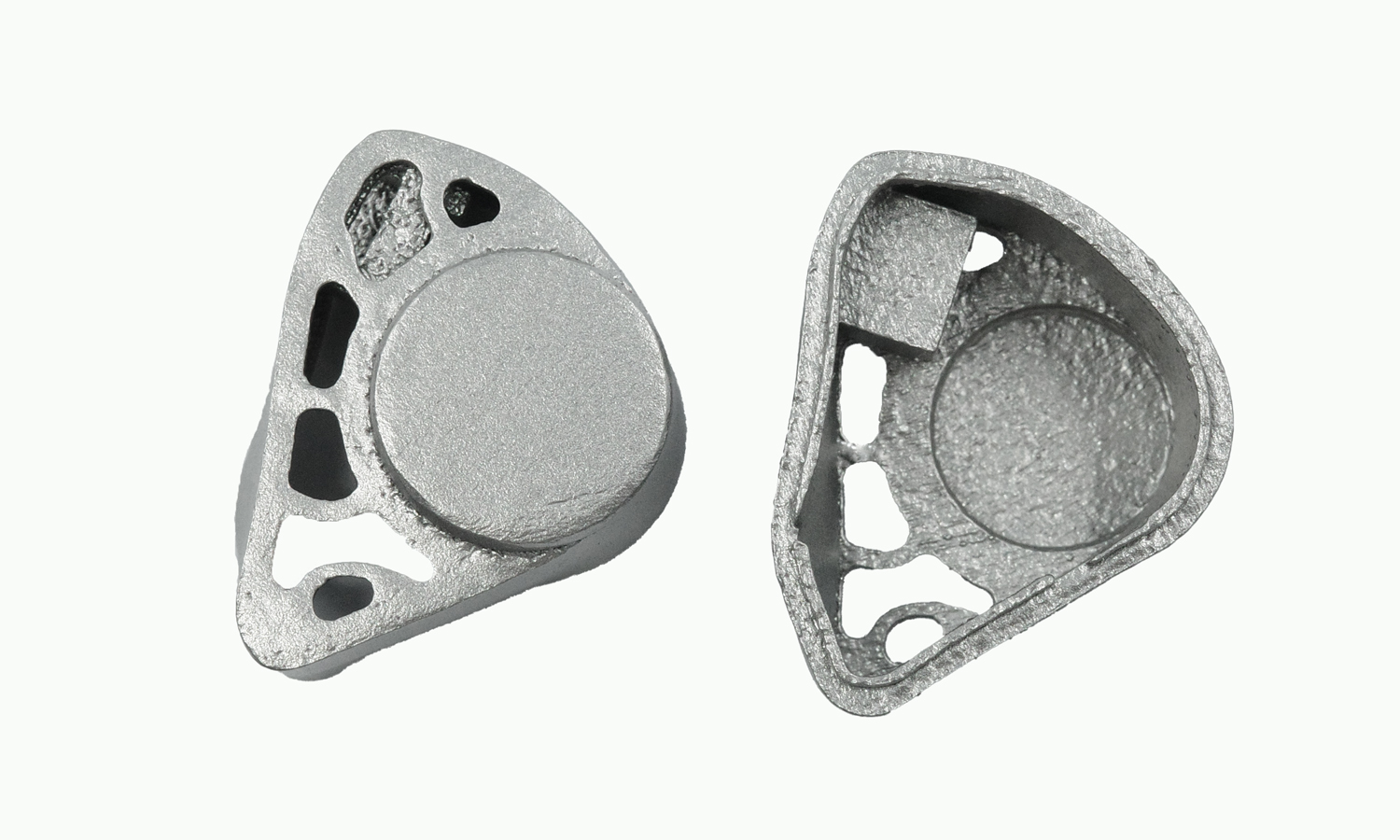

In this audio device project, the client provided two key components from a premium earbud design-each with very different functional requirements. FacFox supported the entire fabrication process using a mix of metal 3D printing, machining, and precision finishing.

IN718 Internal Body – Strength & Complexity

The darker, matte housing is made from Inconel 718, produced via SLM metal 3D printing. As a nickel-based superalloy widely used in aerospace, IN718 offers:

- High strength and fatigue resistance

- Excellent heat and corrosion stability

- Capability to form complex internal cavities

The rougher texture is typical for functional interior parts and helps maintain structural integrity while minimizing unnecessary post-processing.

Polished Aluminum Alloy Frame – Lightweight & Aesthetic

The glossy silver shell is fabricated from aluminum alloy, then CNC-finished and polished. This component prioritizes:

- Low weight for comfortable daily wear

- A smooth, consumer-grade appearance

- Precise clip and mounting features for internal electronics

The contrast between the two materials-rugged IN718 inside and a sleek aluminum shell outside-perfectly reflects the balance between durability and comfort required in high-end earbuds.

Why Metal Additive Manufacturing Was Ideal

Earbud housings involve tiny geometries that are challenging with traditional tooling. Metal AM allowed:

- Rapid prototyping without molds

- High accuracy on small, complex shapes

- Material optimization between structural strength and user comfort

- Fast design iterations and seamless integration with electronics

FacFox Metal Fabrication Capabilities

FacFox provides a full suite of metal manufacturing options:

- SLM/DMLS metal 3D printing: IN718, 316L, Ti64, Aluminum, CoCr, Copper, and more

- CNC machining for precision surfaces

- Post-processing: polishing, bead-blasting, heat treatment, coating

- Engineering support for DFAM, tolerance planning, and assembly fitting

From earbuds to aerospace-grade components, we help clients turn advanced metal designs into production-ready results.

Bring Your Metal Parts to Life

Whether you need prototypes or end-use metal components, FacFox delivers accuracy, durability, and beautiful finishes-all in one place.

¤æē Start your metal manufacturing project with FacFox today!

Solution

- Step 1: 3D model design and refinement. The earbud housing and outer frame were designed in CAD software. Mounting features, internal cavities, and snap details were refined and checked for fit with the electronic components.

- Step 2: Preparation for metal 3D printing. The IN718 internal body was oriented and prepared in the build software. Supports were generated where necessary, and process parameters were set according to the alloy and required accuracy.

- Step 3: IN718 earbud body printing. The internal earbud body was produced by SLM metal 3D printing. Layers of IN718 powder were spread and were selectively melted by a laser until the full 3D shape was built.

- Step 4: Powder removal and support removal. After printing, excess IN718 powder was removed from the build chamber and internal cavities. Support structures were cut away, and the part was separated from the build plate.

- Step 5: Heat treatment and stress relief. The IN718 part was placed in a furnace and was heat-treated for stress relief. This step ensured dimensional stability and enhanced mechanical performance.

- Step 6: Initial surface finishing of IN718 part. The printed body was sandblasted and lightly ground where required. Critical interfaces were deburred, while non-visible areas were left with their functional rough texture.

- Step 7: Machining of aluminum alloy frame. The outer earbud frame was machined from aluminum alloy stock. CNC milling and drilling operations were performed to form the outer profile, clip features, and mounting holes.

- Step 8: Polishing of aluminum outer frame. The aluminum frame was then filed, sanded, and progressively polished. The visible surfaces were brought to a smooth, glossy finish suitable for a consumer electronic product.

- Step 9: Dimensional inspection and fitting. Both metal components were measured with precision tools, and key dimensions were verified. The IN718 body and aluminum frame were test-fitted to confirm proper alignment with each other and with the internal electronics.

- Step 10: Cleaning and final quality check. All parts were ultrasonically cleaned and dried. A final visual and functional inspection was performed before the components were approved and prepared for shipment to the client.