Gallery

About Project

FDM 3D printing is a popular and versatile technology that can create durable and functional parts from thermoplastic materials.б═One of the materials that can be used for FDM 3D printing is polycarbonate (PC), which is a strong, tough, and transparent polymer that has many applications in engineering and electronics.б═PC has high impact strength, dimensional stability, electrical properties, and resistance to heat and UV radiation.б═

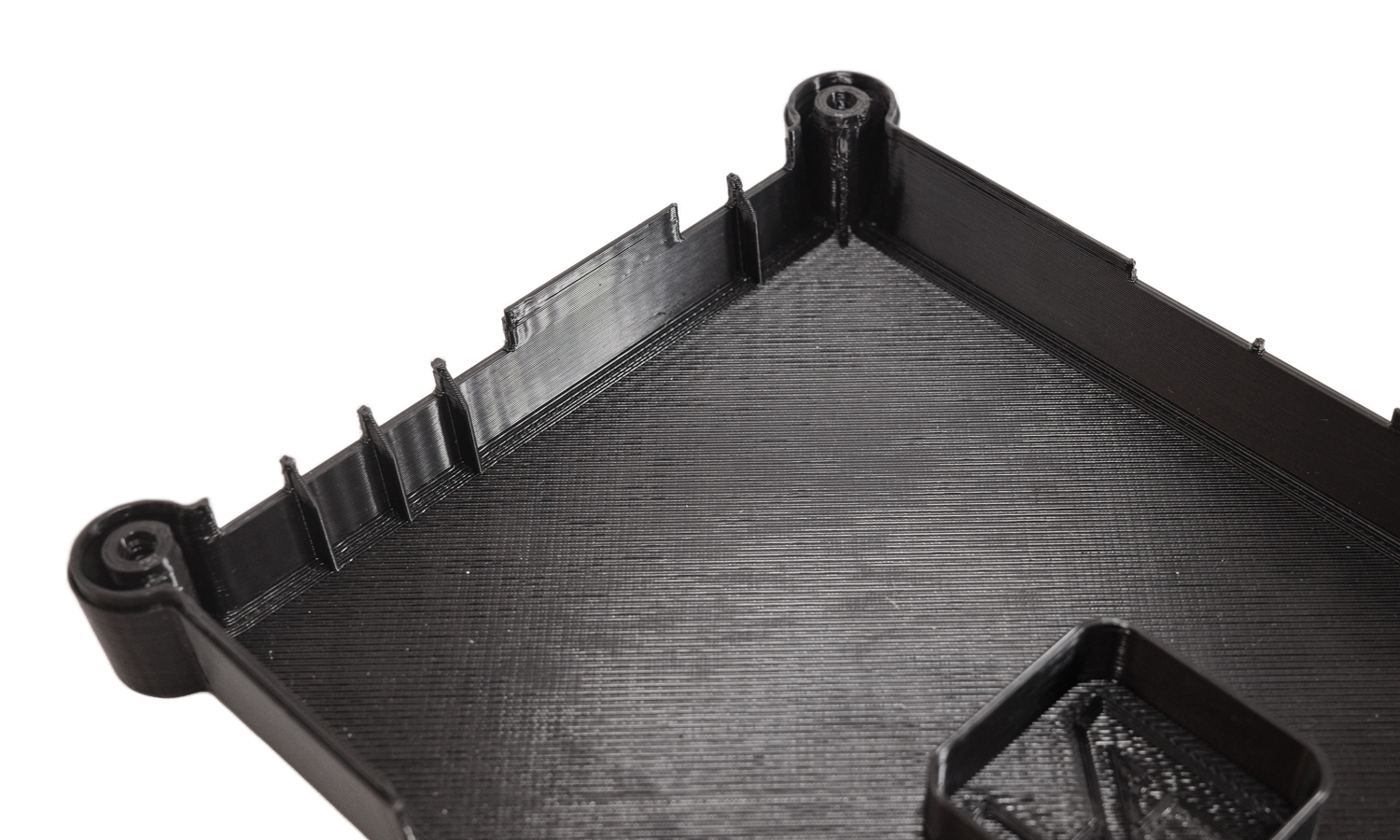

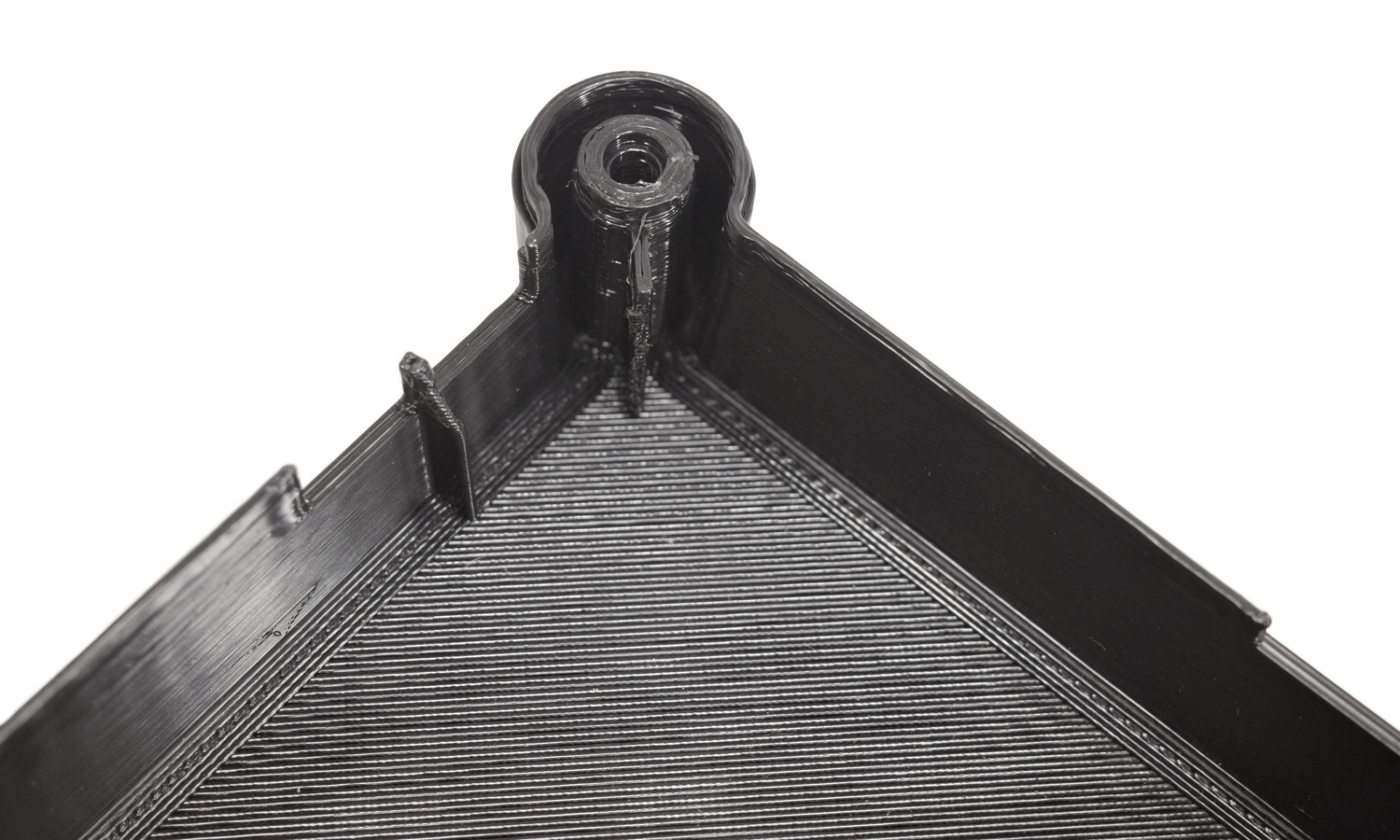

One of the possible uses of FDM 3D printed PC is to create a CPU cooler case. A CPU cooler case is a device that encloses the CPU cooler and protects it from dust, debris, and physical damage. It also helps to improve the airflow and cooling performance of the CPU cooler by directing the air to the heat sink and fan. A CPU cooler case can be customized to fit different sizes and shapes of CPU coolers, as well as to match the aesthetic of the PC build.

An FDM 3D-printed black PC CPU cooler case can offer several advantages over other types of CPU cooler cases. First, it can be easily designed and printed with precise dimensions and features, such as bosses, holes, and letters. Second, it can be made with a high-quality finish and a sleek appearance, thanks to the smooth and glossy surface of PC. Third, it can withstand high temperatures and vibrations, as well as provide good insulation and protection for the CPU cooler.

To illustrate these benefits, I have created a graphic artwork of an FDM 3D-printed black PC CPU cooler case using my own words and knowledge. The case is about 2 inches wide, 3 inches long, and 1 inch tall. There are bosses in each corner, and there is a square hole with the letter N in the center. The case has a simple and elegant design that complements the black color of the PC. The case also fits snugly over the CPU cooler and allows sufficient airflow through the hole.

If you are interested in FDM 3D printing your own black PC CPU cooler case, or any other electronic parts, you might want to check out FacFoxБ─≥s manufacturing services for electronics. FacFox is a leading online platform that offers fast, reliable, and affordable FDM 3D printing services for various materials, including PC. FacFox can help you turn your design into reality with high-quality results and professional support. You can upload your file, get an instant quote, and place your order online with just a few clicks. FacFox also provides other services for electronics, such as PCB fabrication, assembly, testing, and packaging. Whether you need a prototype or mass production, FacFox can handle your project with efficiency and expertise.

Solution

- Step 1: A digital design file of the CPU cooler case was created using CAD software. The design file specified the dimensions, features, and shape of the case, such as the bosses, the hole, and the letter N. The design file was then uploaded to the FDM 3D printer.

- Step 2: A spool of black PC filament was loaded into the FDM 3D printer. The filament was a thermoplastic material that could be melted and extruded by the printer. The printer also had a heated nozzle and a build platform that could move along the X, Y, and Z axes.

- Step 3: The FDM 3D printer started to print the CPU cooler case layer by layer. The printer heated the PC filament to its melting point and extruded it through the nozzle in thin strands. The printer followed a predetermined path based on the design file and deposited the melted material on the build platform. The material cooled and solidified quickly after being extruded. The printer repeated this process until it completed one layer of the case.

- Step 4: The 3D printer moved to the next layer of the case. The build platform lowered by a small amount and the printer extruded another layer of material on top of the previous one. The printer fused the layers together by applying heat and pressure. The printer continued this process until it finished all the layers of the case.

- Step 5: The case was removed from the build platform. The case was inspected for any defects or errors and post-processed if needed. Post-processing could include removing support structures, sanding, smoothing, or painting the case. The case was then ready to be fitted over the CPU cooler.