- SLA 3D Printed Resin Airplane Plastic Model Kit Wall Decoration

- SLA 3D Printed Arnold Schwarzenegger Bust Resin Statue

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

Transform your electronic devices with FacFox's exceptional SLA 3D-printed clear resin enclosures. Our state-of-the-art technology brings your design visions to life with unparalleled clarity and precision.

Showcase Your Device in Style:

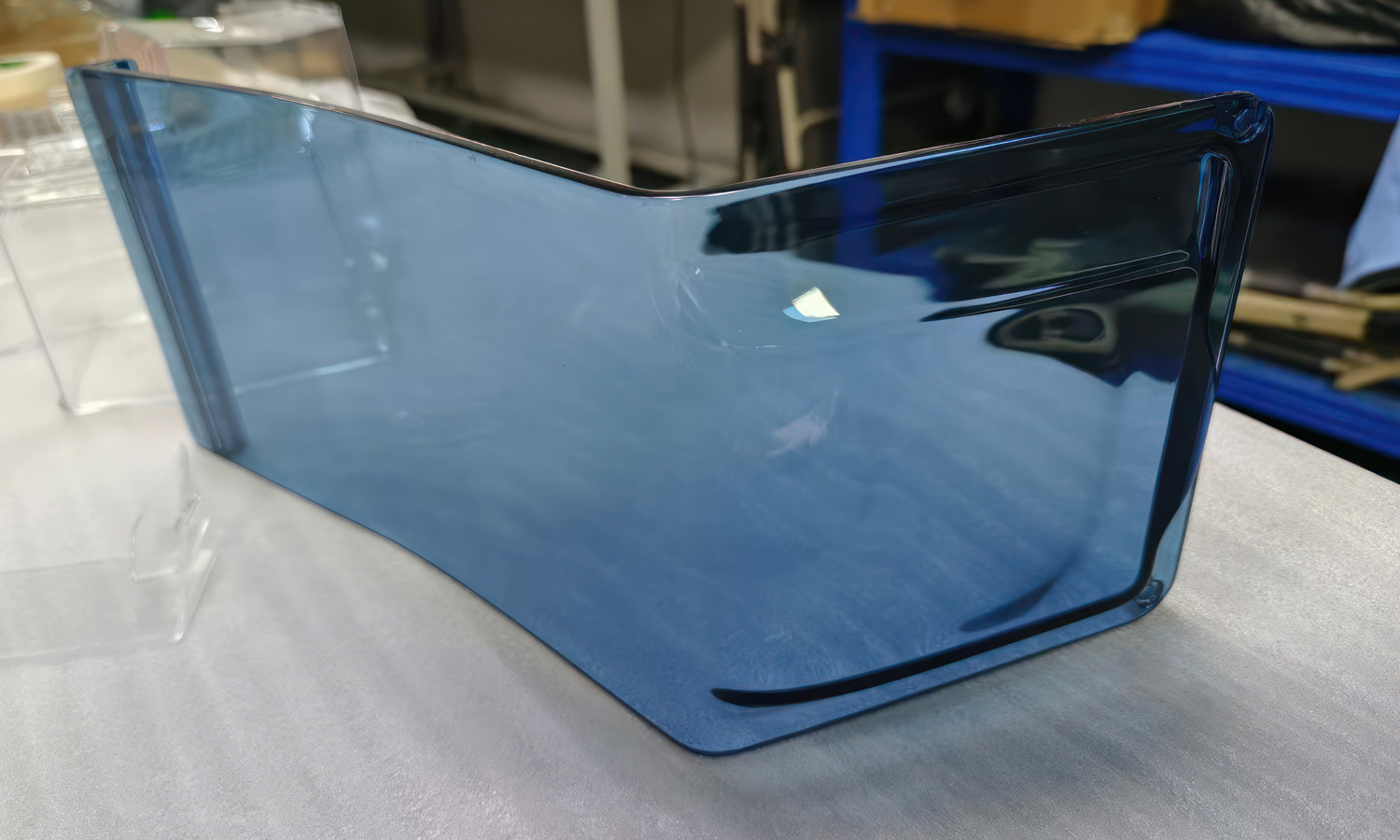

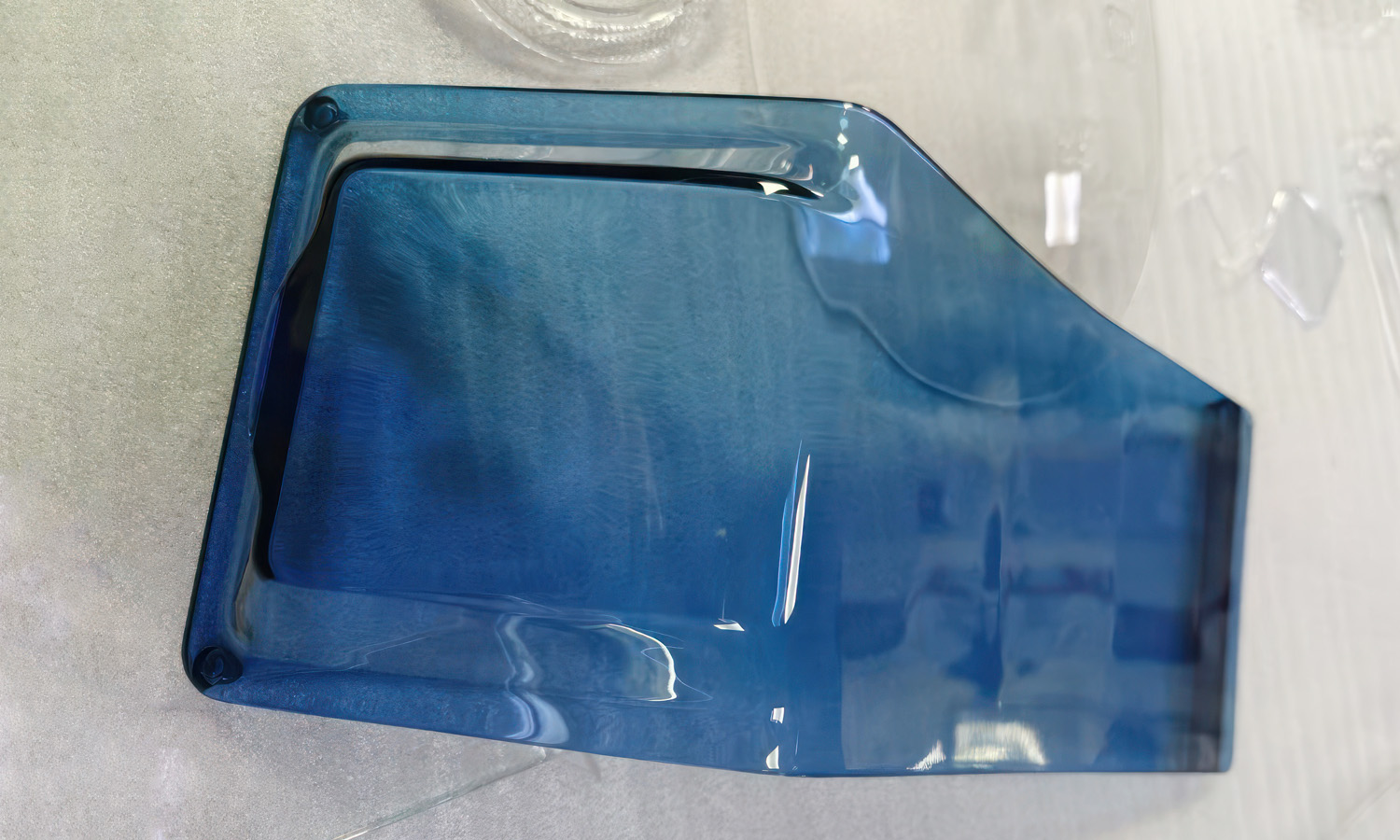

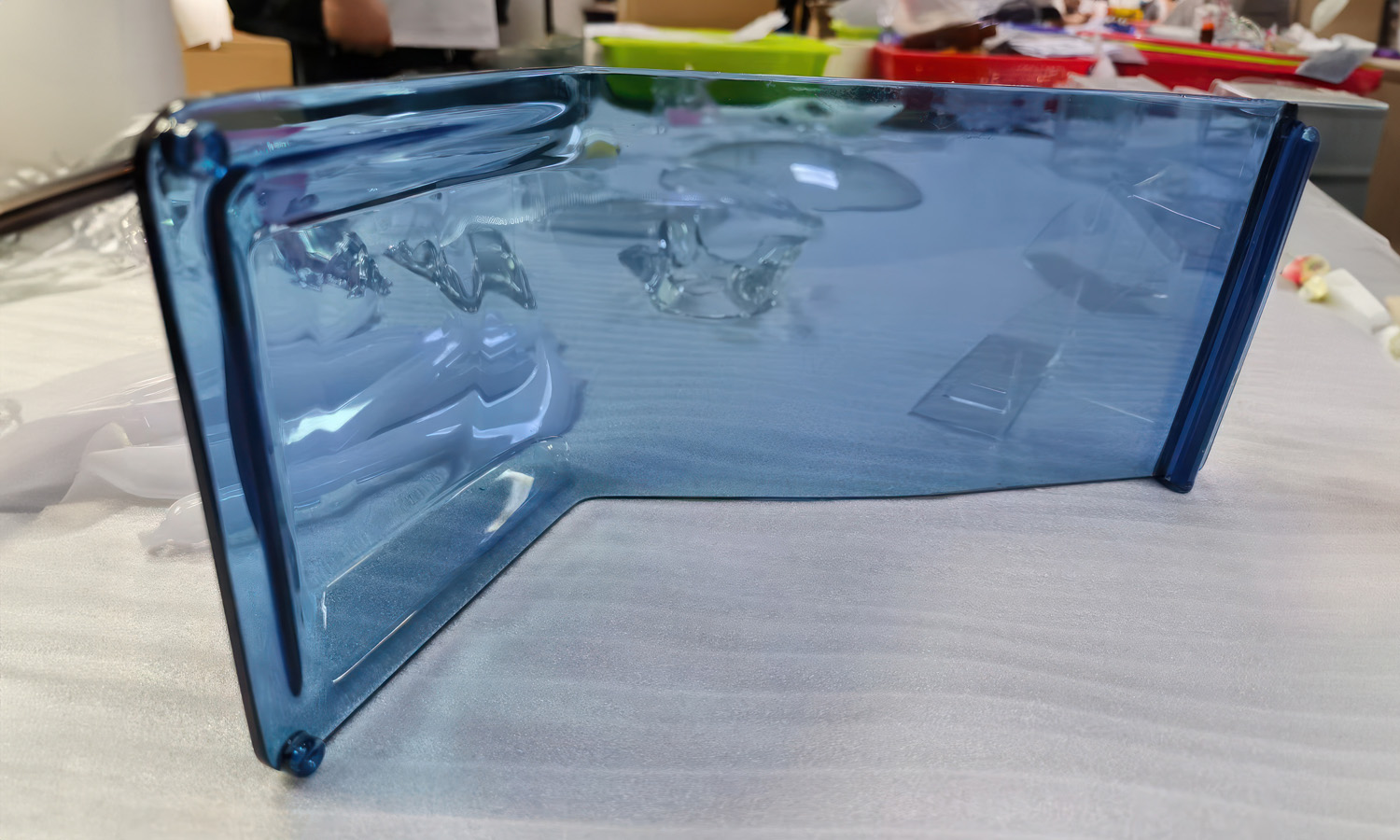

Imagine a sleek, rectangular enclosure with a captivating obtuse angle bend. Our clear resin showcases the beauty of your device while adding a touch of modern elegance. The smooth edges, rounded corners, and glossy finish create a mesmerizing visual experience.

Unleash Your Creativity:

FacFox's clear resin printing offers endless possibilities. From intricate circuit board covers to unique display windows, we can help you create custom enclosures tailored to your exact specifications. Whether you're a hobbyist or a business, our expertise will bring your ideas to life.

Benefits of Clear Resin Enclosures:

- Enhanced Aesthetics: Showcase your device's inner workings and create visually stunning products.

- Durability: Our clear resin enclosures are strong and built to last.

- Customization Freedom: Design and create unique enclosures with unmatched precision.

Partner with FacFox

As a leader in SLA 3D printing, FacFox is committed to delivering exceptional quality and service. Let us help you transform your electronics with our stunning clear resin enclosures.

Solution

- Step 1: Designing the Model. Initially, a digital 3D model was created, tailored to the specifications of a rectangle resin part bent at an obtuse angle with smooth edges and rounded corners.

- Step 2: Preparing the Printer. The SLA printer was set up, ensuring the resin tank was filled with SLA Clear Resin and the build platform was calibrated correctly.

- Step 3: Printing the Base Layer. The build platform was lowered into the resin vat, and a UV laser was employed to cure the first layer of the resin, adhering it to the build platform.

- Step 4: Building the Object. Subsequent layers were then cured on top of the previous ones, with the build platform moving upward after each layer was solidified.

- Step 5: Forming the Part. As the layers built up, the part gradually took shape, the full part was formed together with the detailed structures.

- Step 6: Post-Processing. After printing, the object was rinsed with isopropyl alcohol to remove any uncured resin and then post-cured under UV light to ensure thorough hardening. Then it was soaked in blue solution to be dyed into blue color.

- Step 7: Finishing Touches. Finally, the part was sanded to smooth out any imperfections, and a glossy coating was applied to give it a reflective finish.