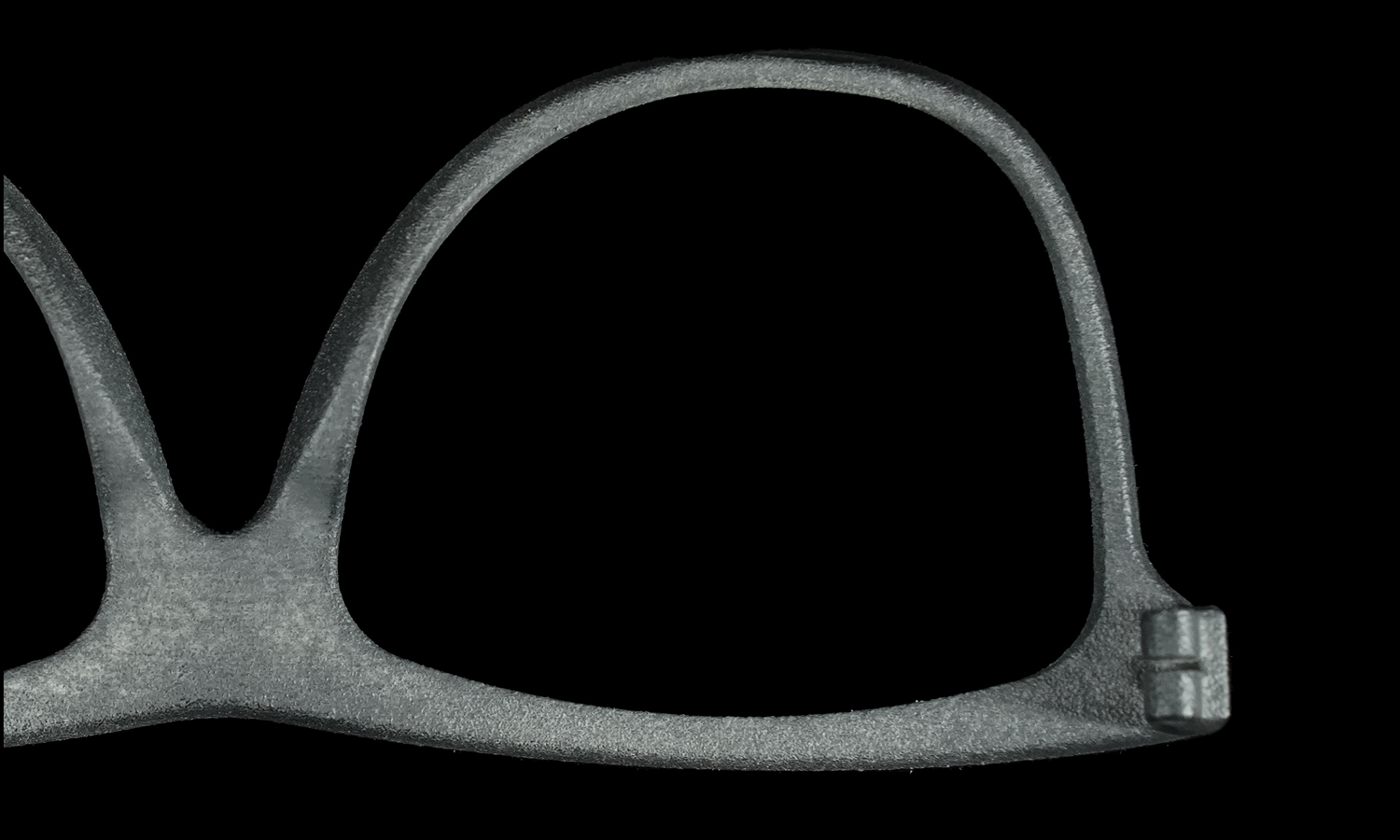

- MJF 3D Printed Nylon PA 12 Thin-framed Glasses Frame Dyed Black Sand-blasted

- MJF 3D Printed TPU Strut Lattices Vapor Smoothed Dyed Black

Gallery

About Project

If you are looking for a pair of glasses that are simple and elegant, you should check out MJF 3D printed and sand-blasted nylon PA 12 bold-framed glasses. These are not your flashy glasses, but a classic piece that matches any outfit and occasion. MJF 3D printing technology allows you to create a thick and sturdy frame that has a smooth and matte surface. Nylon PA 12 is a durable and flexible material that can resist impact, abrasion, and chemicals. It also has a low friction coefficient that makes it comfortable to wear.

You can customize your MJF 3D printed and sand-blasted nylon PA 12 bold-framed glasses with FacFoxŌĆÖs online 3D printing platform. FacFox is a leading provider of MJF 3D printing service that offers high-quality and affordable solutions for various applications. You can upload your own design or choose from their existing models, select your material and color options, and get an instant quote. FacFox will print your glasses with their advanced MJF machines and ship them to you in no time.

DonŌĆÖt miss this chance to get your own MJF 3D printed and sand-blasted nylon PA 12 bold-framed glasses. Visit FacFoxŌĆÖs website today and order yours now. You will appreciate the quality and simplicity of these glasses.

Solution

- Step 1: First, the 3D model will be broken down into layers of 0.1 mm on the computer and sent to the 3D printer.

- Step 2: Before printing, we need to fill the tank with MJF Nylon PA12 powders. On a bed pressure, a 0.1 mm thick layer over the whole width is applied.

- Step 3: The material recoater carriage moves across the build area, depositing a thin layer of the powder material. The printing and fusing carriage moves across the build area, preheating the powder to a specific temperature to provide material consistency.

- Step 4: An array of inkjet nozzles fuses agents onto the powder bed in areas that correspond to the partŌĆÖs geometry and properties. After each layer is finished, the build unit retracts to create space for the next layer of material to be deposited.

- Step 5: This process repeats until the build is completed. When the printing process ends, remove the excess powders which also serve as supports. The glass frame was then sand-blasted for a finer surface.