- SLA 3D Printed Suitcase Prototype with Silk-screen Logos

- LCD 3D Printed Detailed Tough Resin Battery Holder Prototype

Gallery

About Project

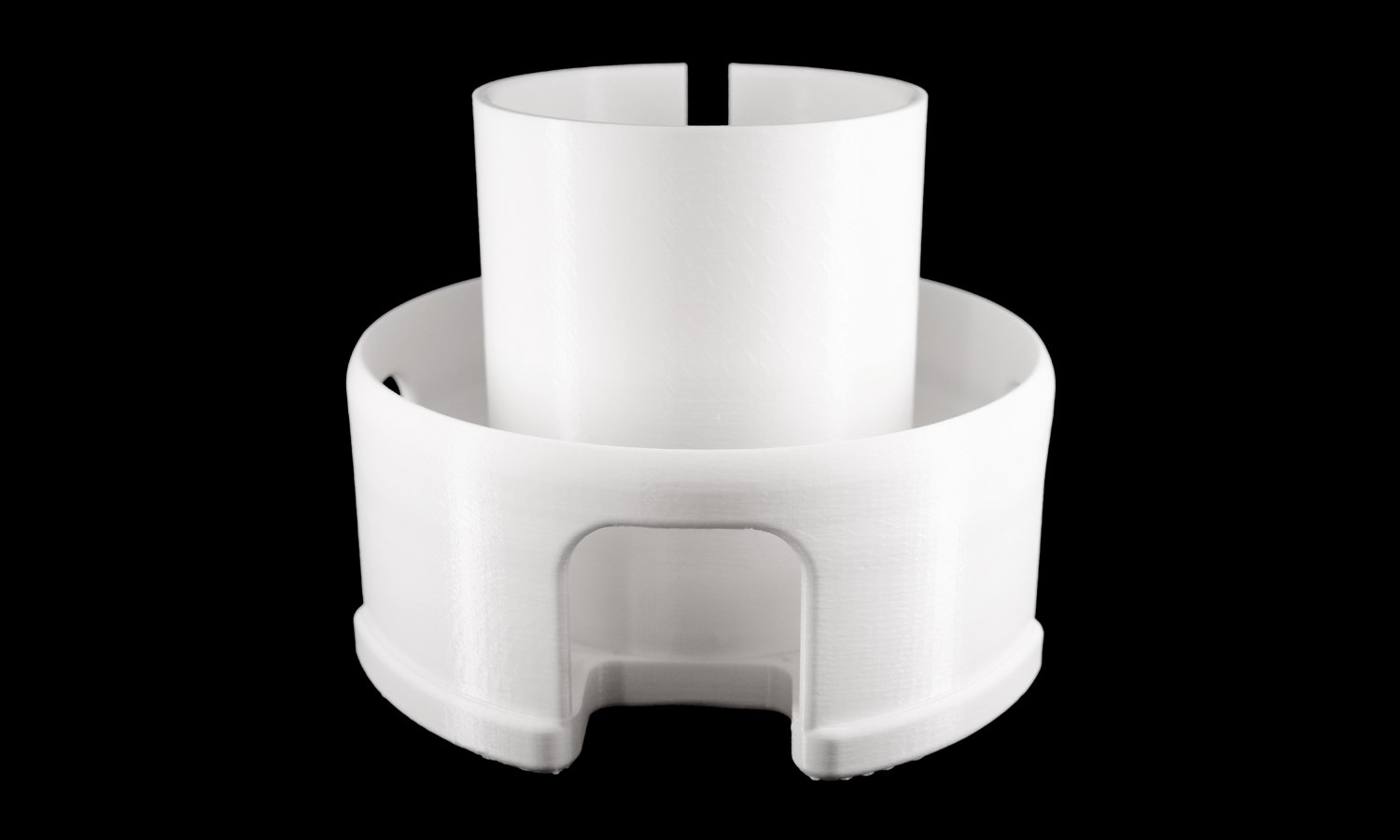

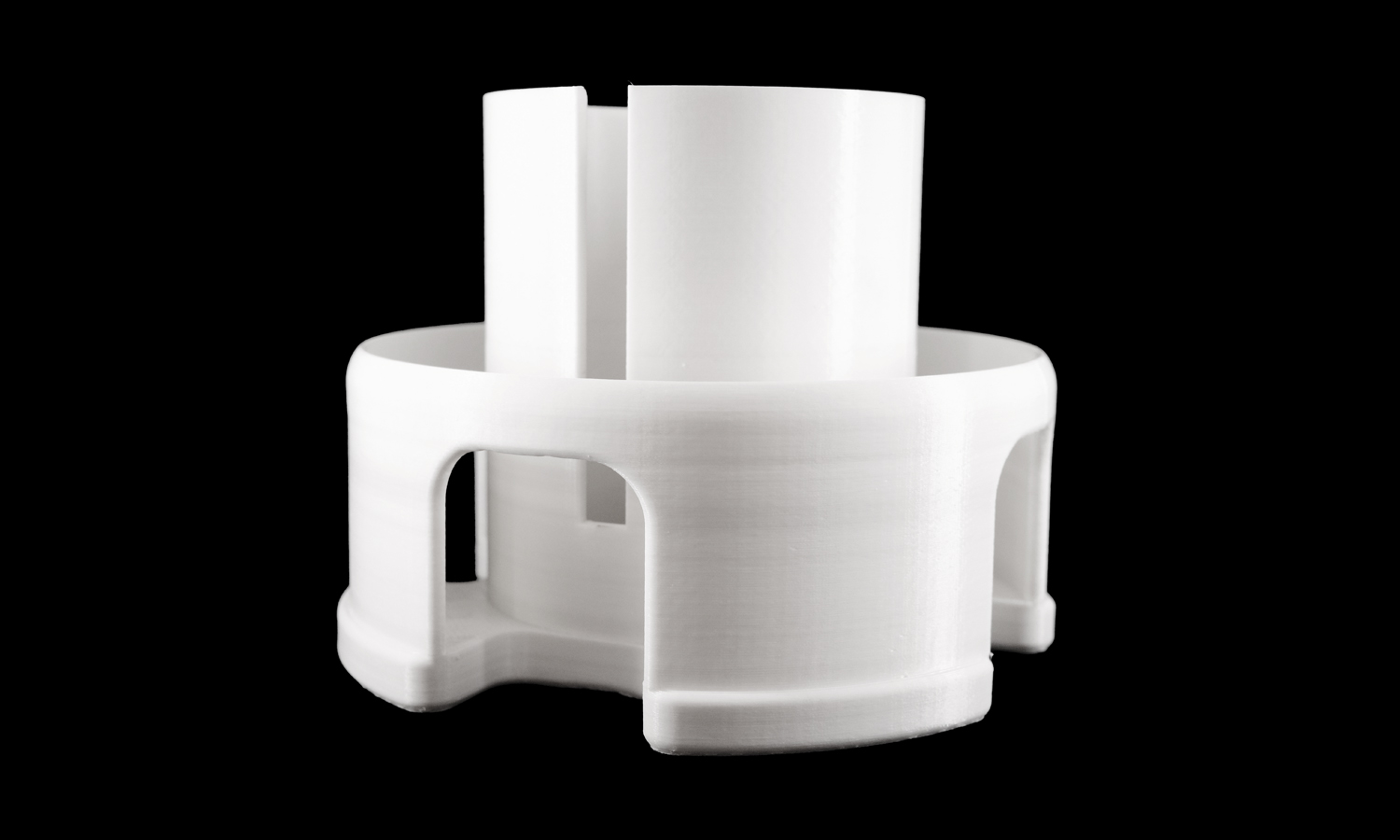

If you are looking for a durable and reliable solution to seal your pipes, you might want to consider FDM 3D-printed large white ABS pipe fitting plugs. These are custom-made plugs that fit snugly into your pipes and prevent leaks or spills. They are made of ABS, a strong and resilient thermoplastic material that can withstand high temperatures and pressures.

The FDM 3D printed large white ABS pipe fitting plugs have a unique design that makes them easy to use and install. They consist of a hollow rod that has a diameter of about 10 cm. The rod is not closed but has a gap, so it has elasticity to fit the pipe. The rod is surrounded by a cap that is hollowed from four directions and is designed to be grabbed or pushed. The cap also has a flange that helps to secure the plug in place.

To use the FDM 3D printed large white ABS pipe fitting plugs, you simply need to insert the rod into the pipe and push the cap part until it reaches the end of the rod. The plug will expand and conform to the shape of the pipe, creating a tight seal. To remove the plug, you just need to pull the cap and the rod will retract and slide out of the pipe.

The FDM 3D printed large white ABS pipe fitting plugs are ideal for applications that require frequent plugging and unplugging of pipes, such as plumbing, irrigation, drainage, or industrial processes. They are also suitable for pipes that have irregular shapes or sizes, as the FDM 3D printing technology can produce customized plugs that match your specifications.

If you are interested in FDM 3D printed large white ABS pipe fitting plugs, you can order them from FacFox, a leading online platform for FDM 3D printing services. FacFox can provide you with high-quality FDM 3D printed products at affordable prices and fast delivery times. You can upload your 3D model or choose from their online catalog of ready-made designs. You can also select from various materials, colors, and finishes to customize your FDM 3D printed products. FacFox has a team of professional engineers and designers who can assist you with your FDM 3D printing needs and ensure your satisfaction. Visit their website facfox.com to learn more and place your order.

Solution

- Step 1: A 3D model of the plug was created using CAD software. The model was then sliced into thin layers and converted into a G-code file that contained the instructions for the FDM 3D printer.

- Step 2: The FDM 3D printer was prepared by loading the ABS filament and setting the temperature and speed parameters. The printer was also calibrated to ensure the accuracy and quality of the print.

- Step 3: The G-code file was sent to the FDM 3D printer and the printing process was started. The printer extruded the melted ABS filament layer by layer, following the shape of the plug. The layers were fused together to form a solid object. The printing process took about an hour to complete.

- Step 4: The FDM 3D printed plug was removed from the printer bed and inspected for any defects or errors. The plug was then cleaned and trimmed to remove any excess material or support structures. The plug was also sanded and polished to smooth the surface and improve the appearance.

- Step 5: The FDM 3D printed plug was tested for its functionality and performance. The plug was inserted into a pipe and checked for its fit and seal. The plug was also subjected to various pressure and temperature conditions to evaluate its durability and resistance. The plug was found to meet the specifications and expectations of the customer.