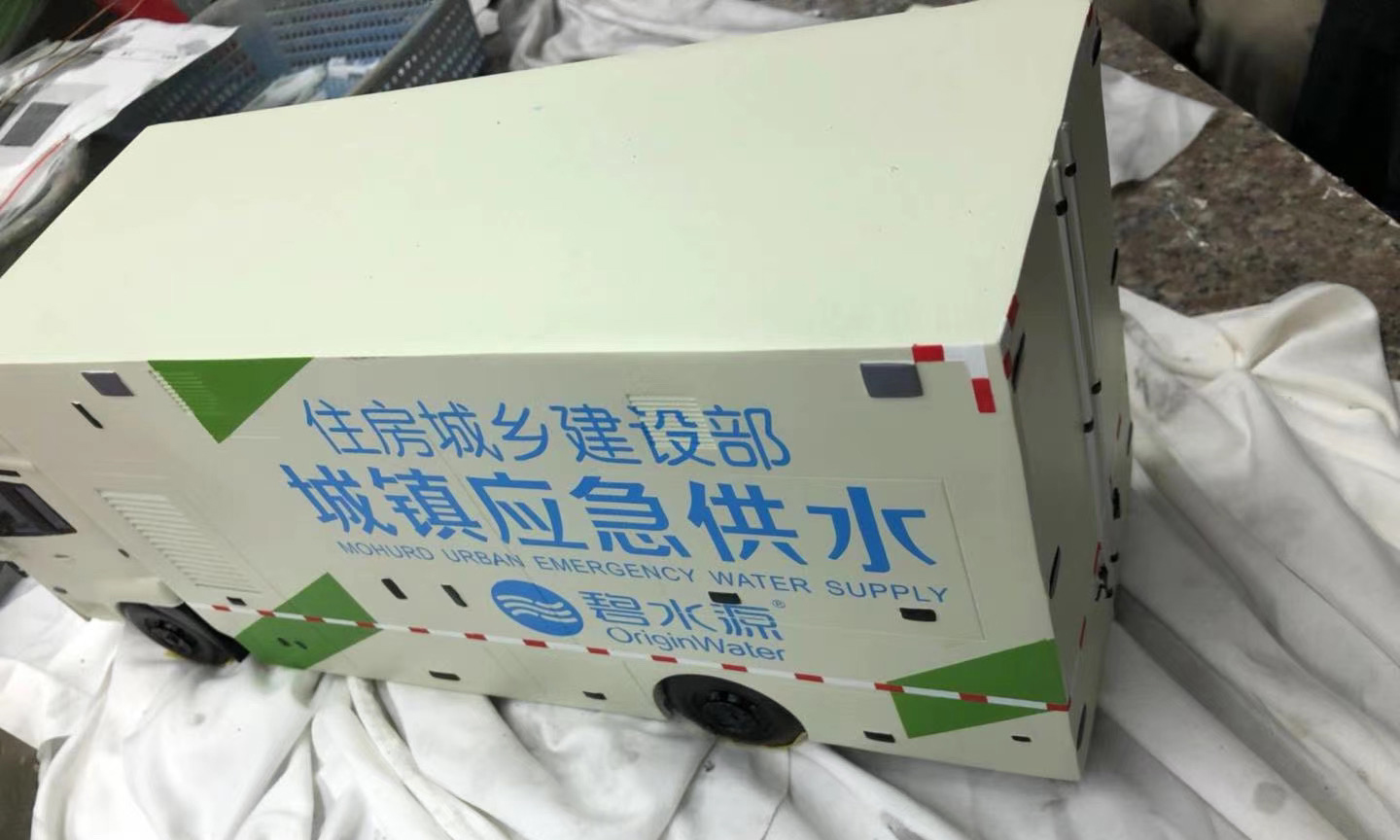

SLA 3D Printed Water Supply Truck Scale Model

Posted on 2020-10-14 in Automotive В· жұҪиҪҰ

Gallery

About Project

An unexpected water supply interruption can occur due to a natural disaster or man-made event. Consider what might happen if we lose access to its water supply. The economic consequences can also be severe.

Beijing OriginWater Technology Co., Ltd., founded in 2001, is dedicated to solving problems like drinking water insecurity. They work with a wide variety of organizations: healthcare facilities, multi-unit residential buildings, hotels, etc.

When competing for government procurement, BOW customized a scale model of the water supply truck they designed beside the preparation of documents. It helps them stand out among various competitors.

Solution

- Step 1: The truck model is comprised of many different parts. We firstly check all the STL files to ensure they are printable and there are enough air gaps for assemblies.

- Step 2: Print the parts with SLA 3D printing technology. SLA is very often used for applications where appearance or a smooth surface finish is required, such as visual prototypes, moulds and hearing aids. It works by using a light source to solidify liquid resins. For this technology, support structures are required to securely attach a part to the print bed and to prevent warping.

- Step 3: Supports used in SLA are very thin and, to save material, only slightly touch the part. This means that they are quite easy to remove manually, either by hand or using pliers. However, since removing supports can leave marks on the final part, sanding will be needed to ensure a smooth surface finish.

- Step 4: Post-curing with UV and Screen-printing. Then assemble and glue all the parts together.