- SLA 3D Printed Iridescent Silver Resin Helmets for Auto Show

- SLA 3D Printed Shuttle Bus with Panoramic Window Resin Prototype

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 4 workdays

Gallery

About Project

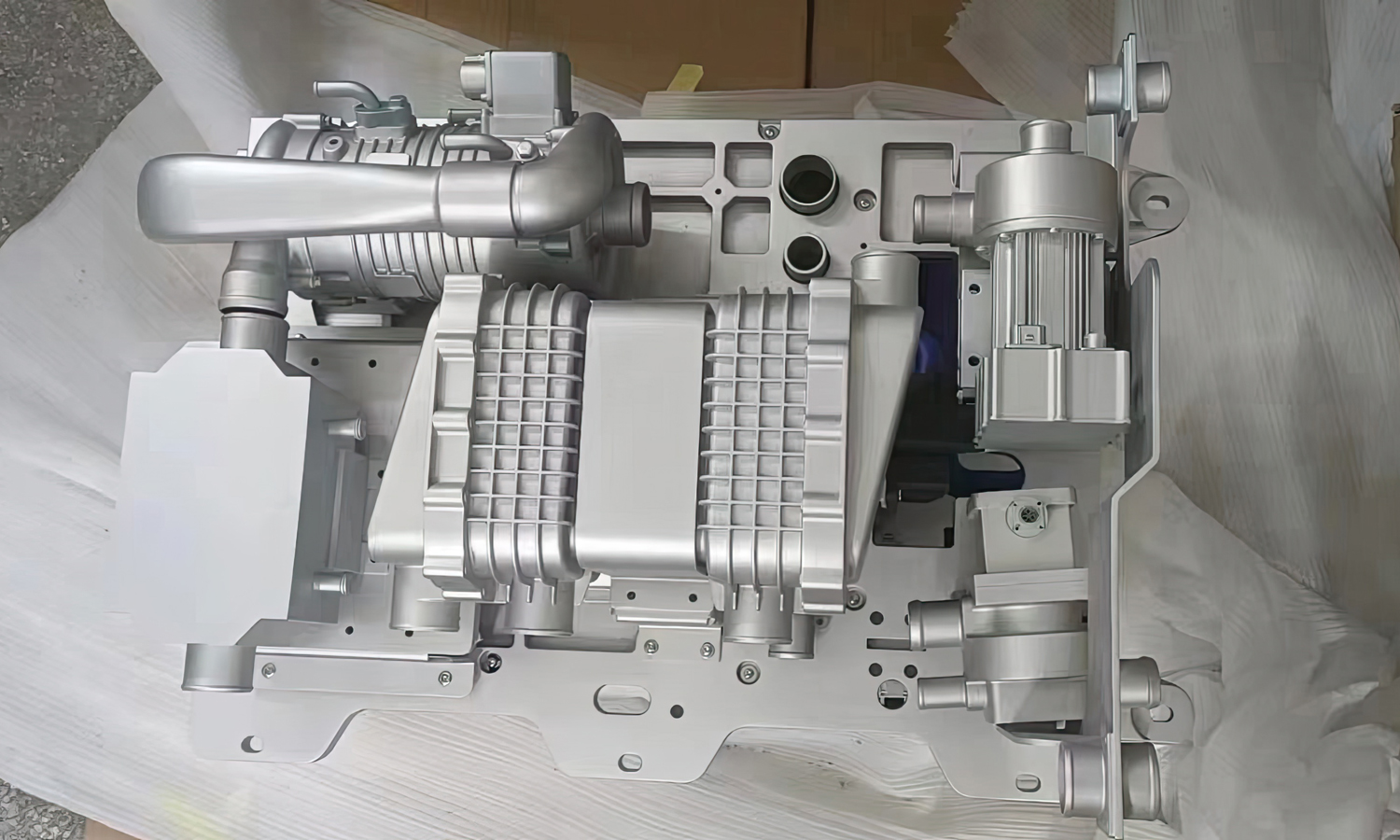

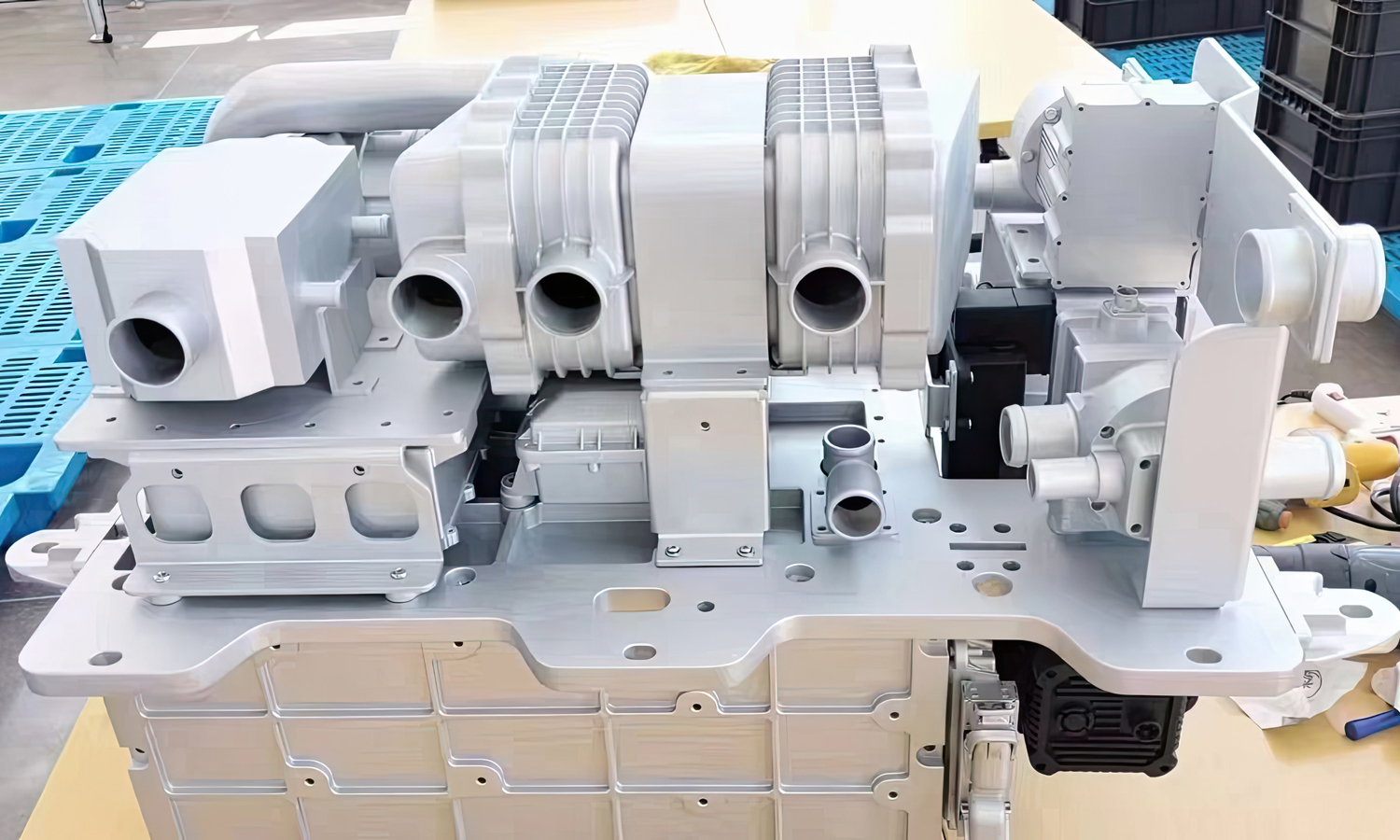

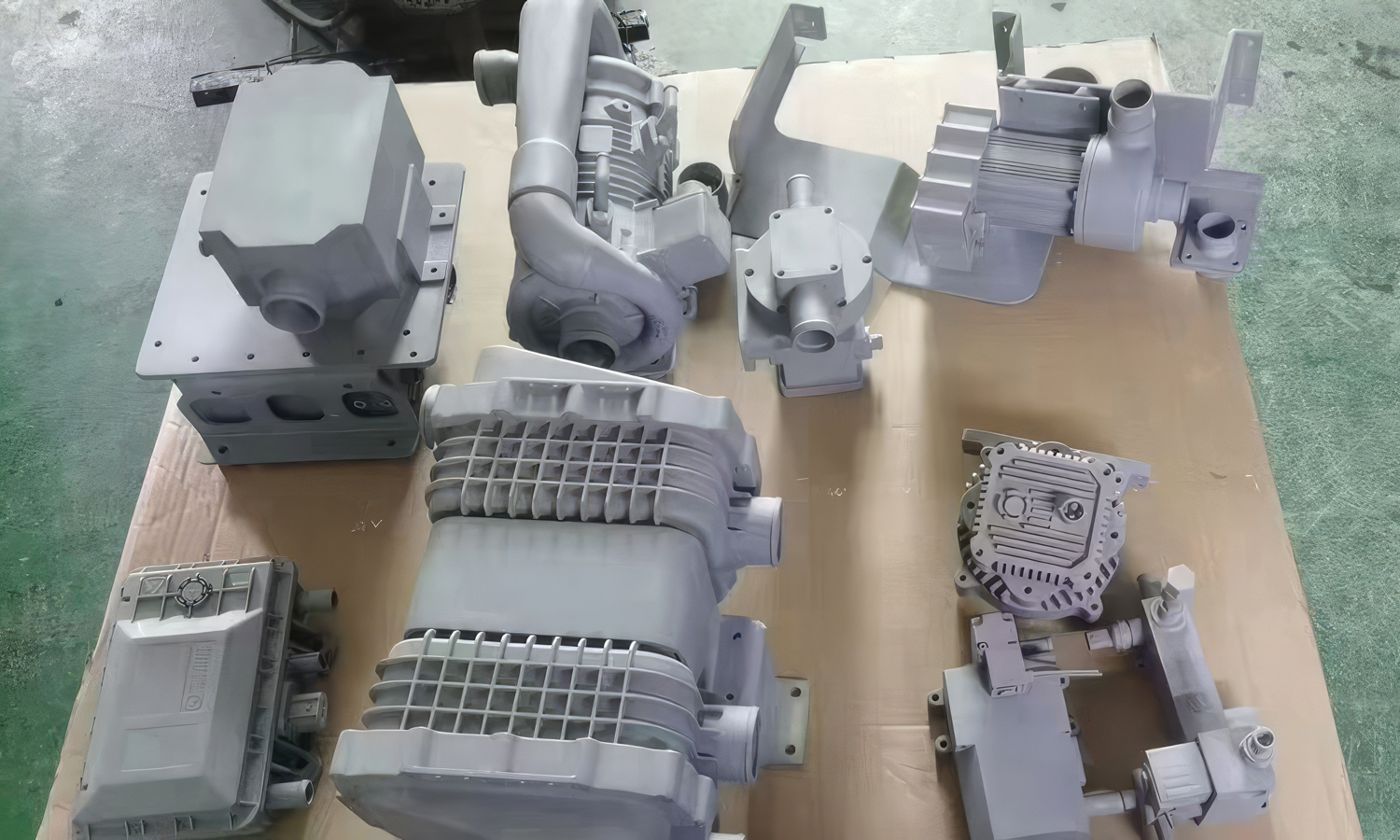

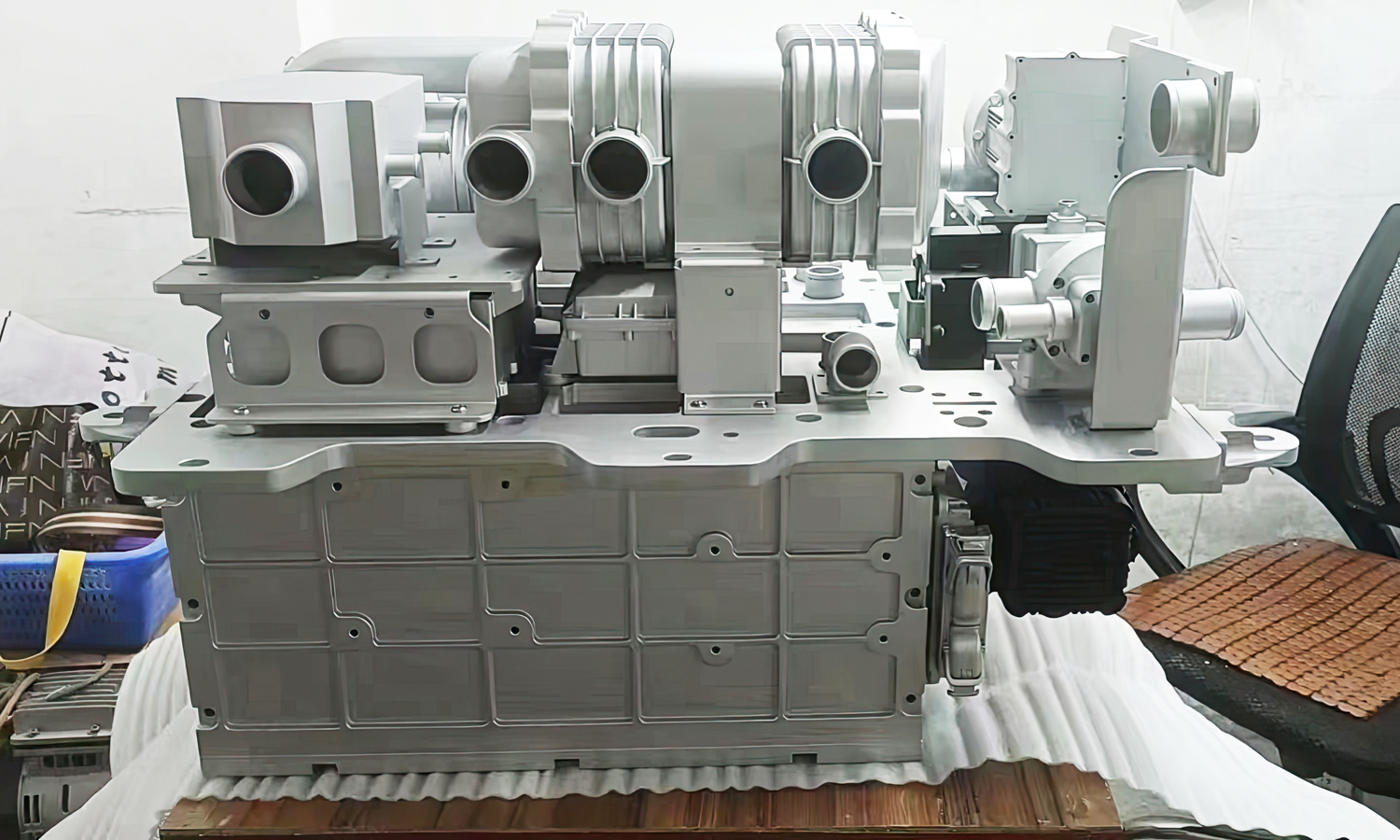

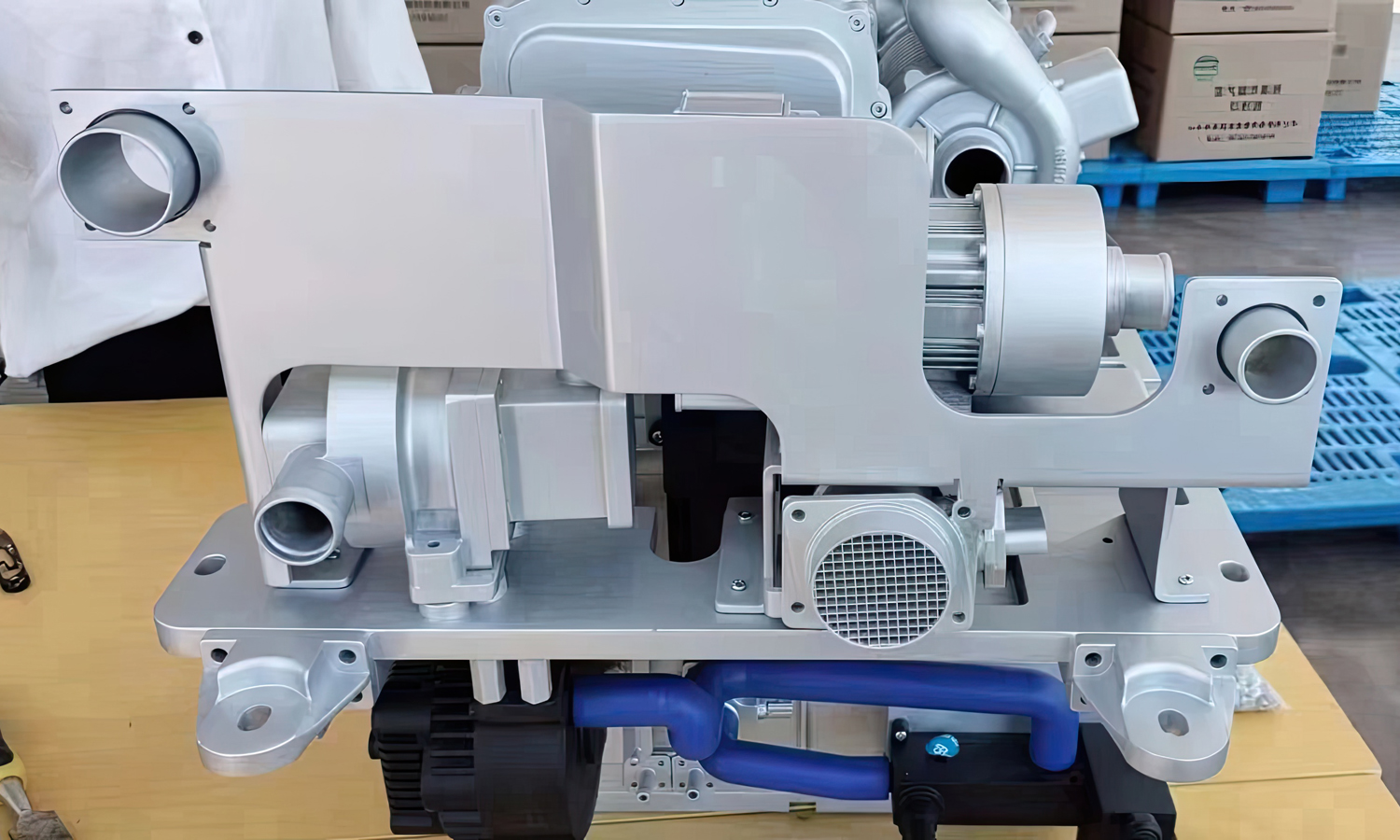

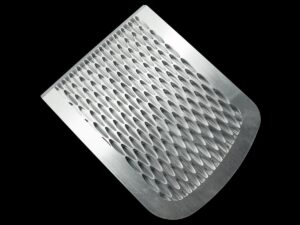

Bring the power and precision of automotive engineering to your desk with a stunning SLA 3D-printed engine display model. Using high-resolution Stereolithography Apparatus (SLA) printing, these models capture the intricate details of an engine block, valve covers, intake and exhaust manifolds, all in a remarkable, display-ready format.

Unlike traditional diecast models, SLA 3D-printed engine models offer unparalleled accuracy and detail. SLA 3D printing utilizes a laser to cure liquid resin layer-by-layer, resulting in a smooth, highly detailed representation of a real engine. This allows you to closely examine the design features and engineering marvels that make an engine function.

These hollow display models are perfect for:

- Car enthusiasts: Showcase your passion for a particular engine or brand with a unique and detailed display piece.

- Designers and engineers: Use a 3D printed model to visualize and discuss engine design concepts with superior detail.

- Trade shows and events: Capture attention at trade shows or automotive events with a show-stopping 3D-printed engine model.

FacFox is a leading provider of SLA 3D printing services for the automotive industry. Our expertise and high-resolution SLA printers can produce realistic and functional prototypes for various automotive applications. Whether you need a concept model to showcase a new engine design or a functional prototype to test fit and performance, FacFox can deliver the high-quality 3D printed parts you need.

Contact FacFox today to discuss your SLA 3D printing needs for the automotive industry, and turn your engine design concepts into reality.

Solution

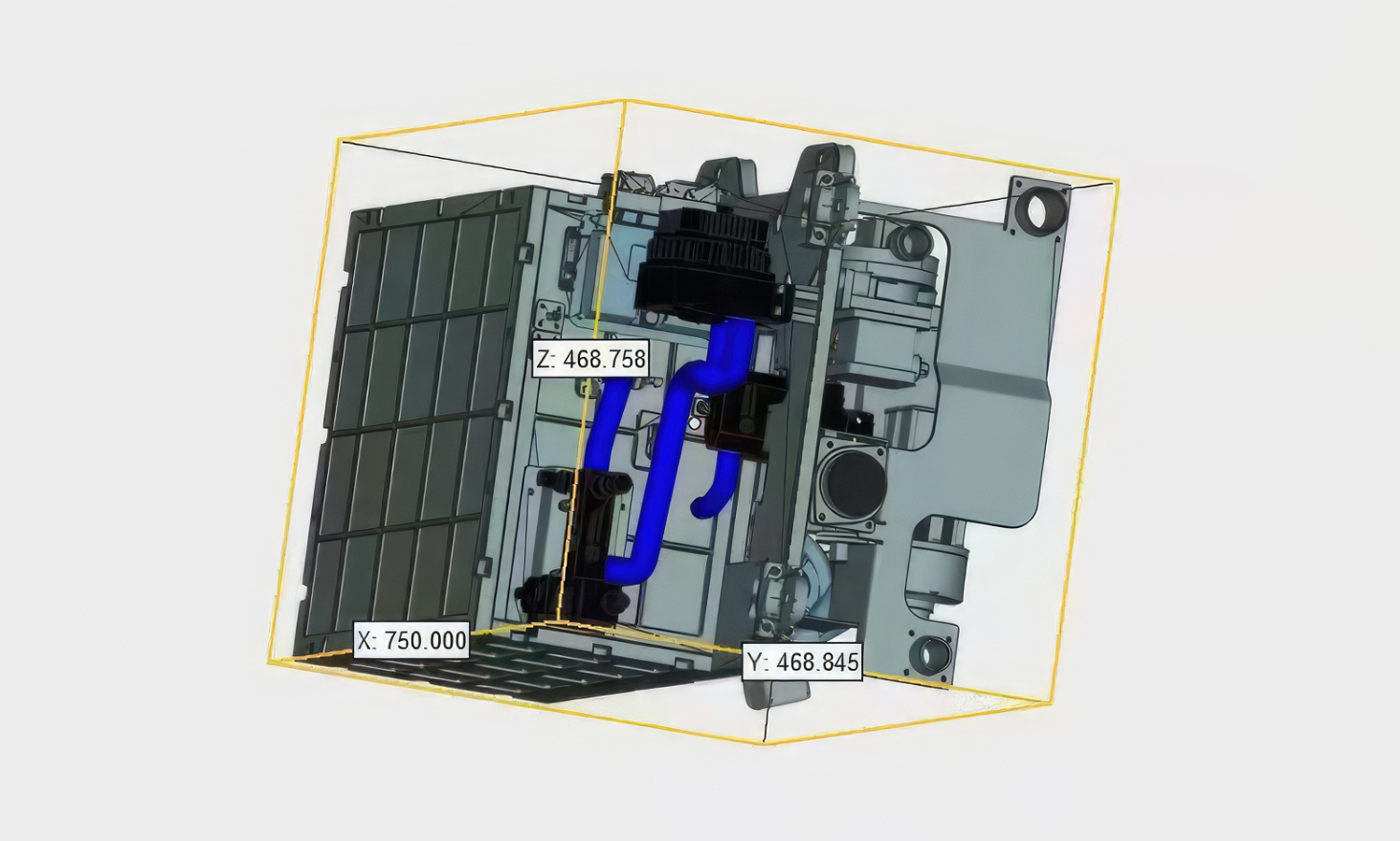

- Step 1: Designing the Model. The digital model of the vehicle engine was created using Solidworks software. Attention was focused on the engine block, ensuring it included representations of the cylinders, pistons, and crankshaft.

- Step 2: Preparing the Printer.┬ĀThe SLA 3D printer was prepared, which involved calibrating the machine and ensuring the resin tank was filled with the appropriate photopolymer resin.

- Step 3: Printing the Engine Block. The SLA printerŌĆÖs laser was passed over the resin, hardening it layer by layer to form the hollowed engine block. The engine block was printed out.

- Step 4: Post-Processing.┬ĀOnce the printing was completed, the model was removed from the printer. It was then washed in isopropyl alcohol to remove any uncured resin.

- Step 5: Curing.┬ĀThe model was placed in a UV curing chamber, where it was exposed to UV light to further harden the resin and improve the modelŌĆÖs strength and stability.

- Step 6: Quality Check.┬ĀThe finished model underwent a quality check to ensure all details were accurately represented and the model was free of defects.

- Step 7: Display Preparation.┬ĀFinally, the SLA 3D printed vehicle engine resin display model was mounted on a display stand, ready to showcase the appearance of the engine block.