- MJF 3D Printed Full-color Female Dinosaur Display Model

- CNC Milled Brass Escutcheon Ring for Sink or Faucet

Gallery

About Project

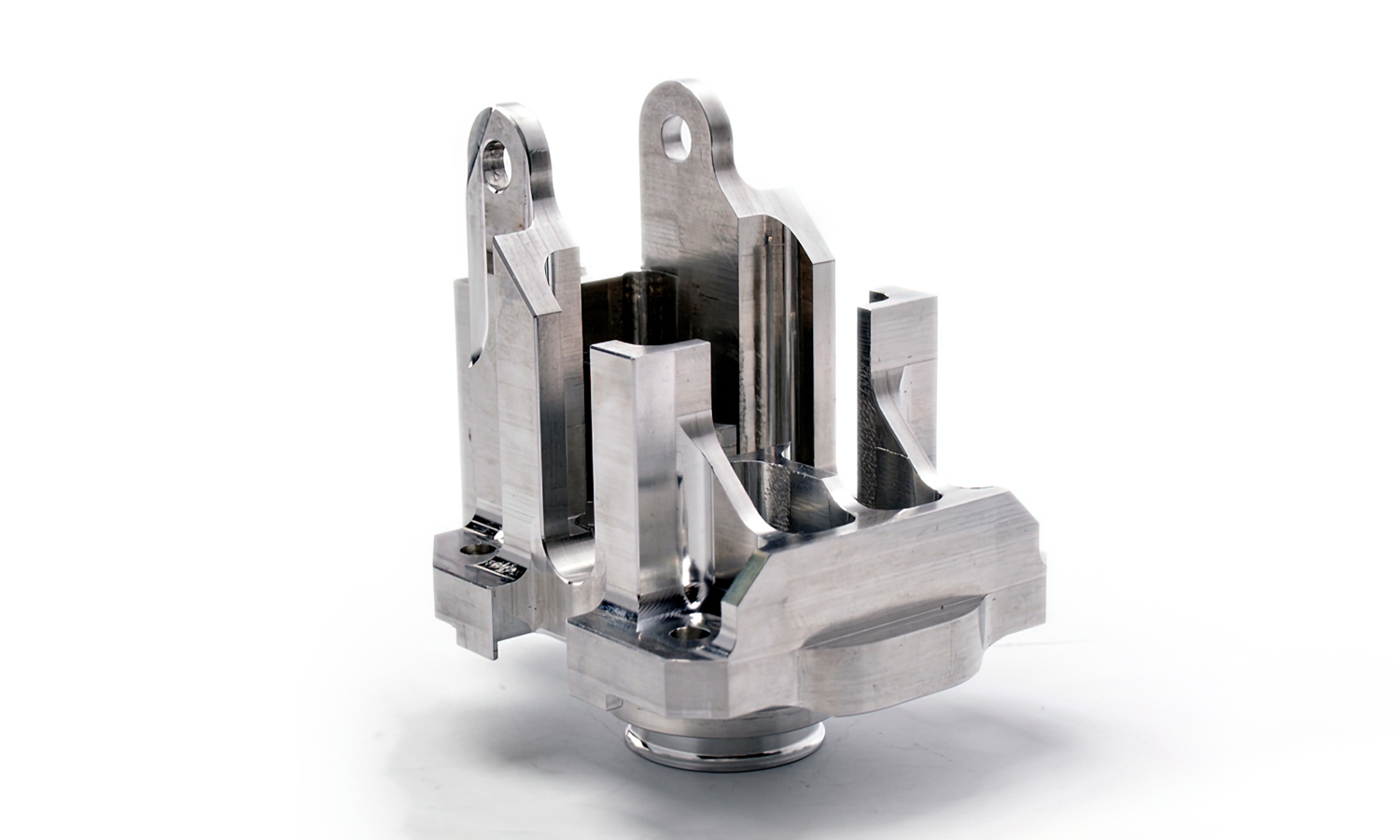

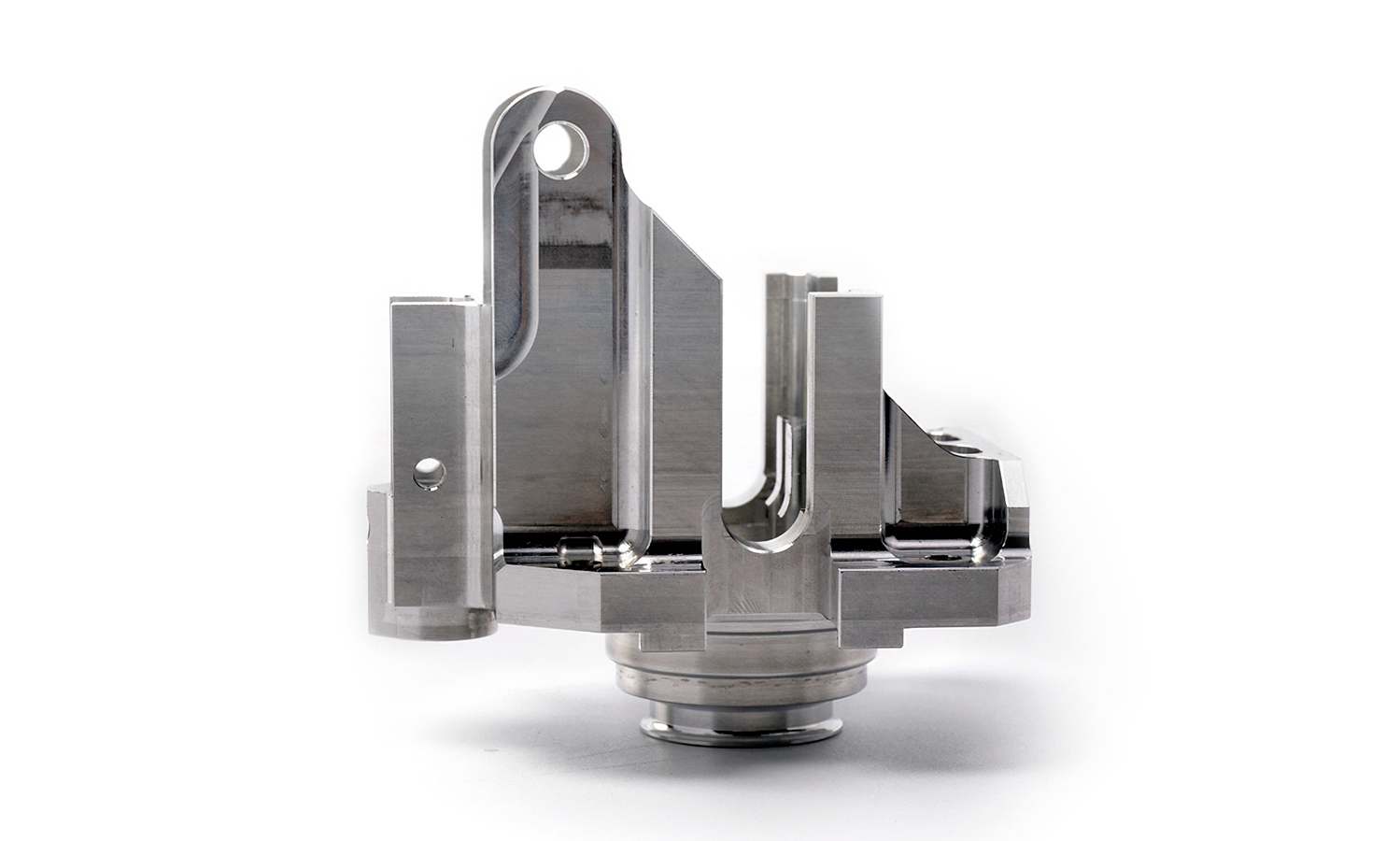

If you are looking for a high-quality and durable ship engine spare part, you might want to consider CNC-milled aluminum alloy. CNC milling is a process that uses computer-controlled machines to create precise and complex shapes from solid materials. Aluminum alloy is a metal that has excellent strength, corrosion resistance, and thermal conductivity, making it ideal for shipbuilding applications.

One example is the CNC-milled aluminum alloy ship engine spare part. It is made of aluminum alloy 5052, which has good weldability and formability. The part has a smooth surface finish and accurate dimensions, thanks to the CNC milling process. The part is designed to fit the ship engine perfectly and perform reliably under harsh conditions.

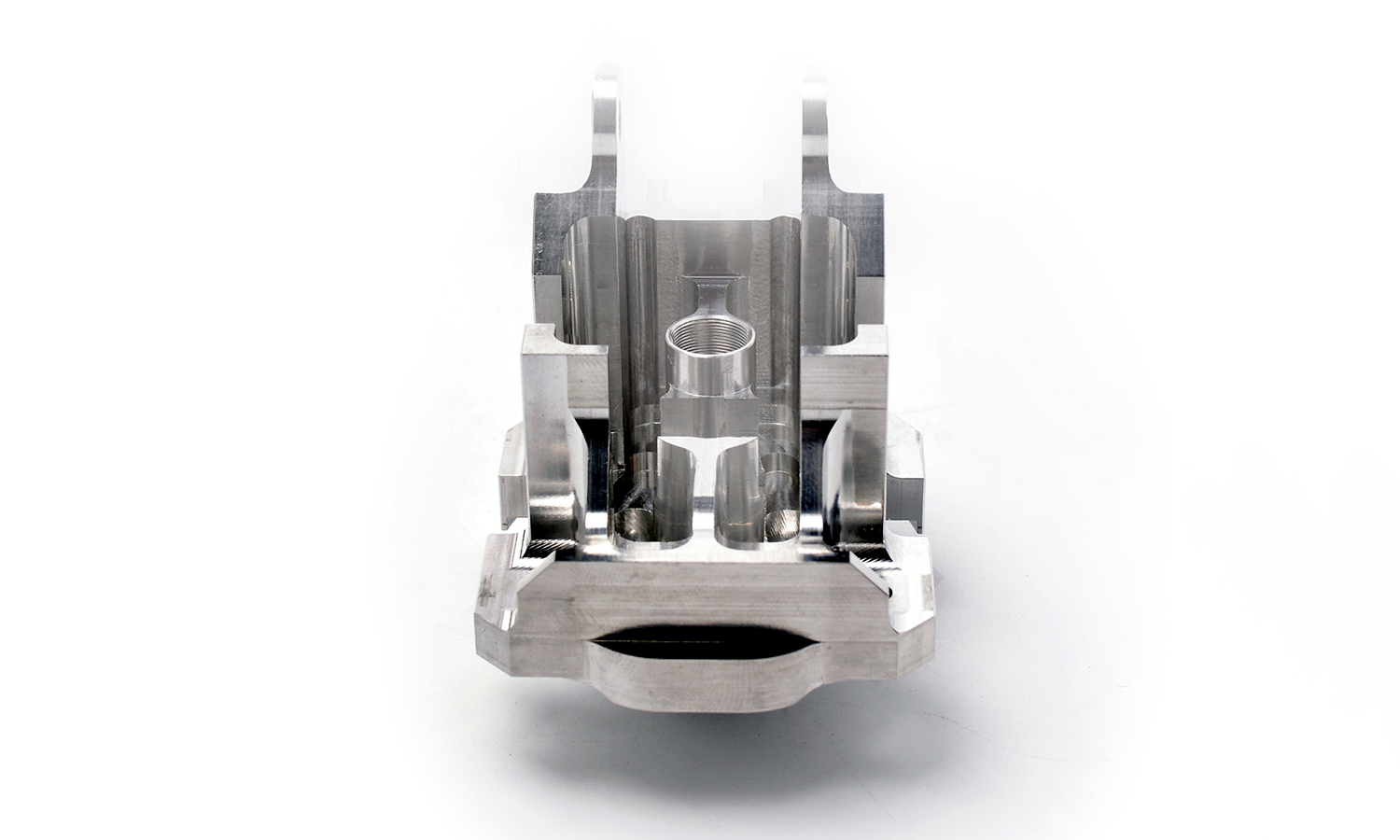

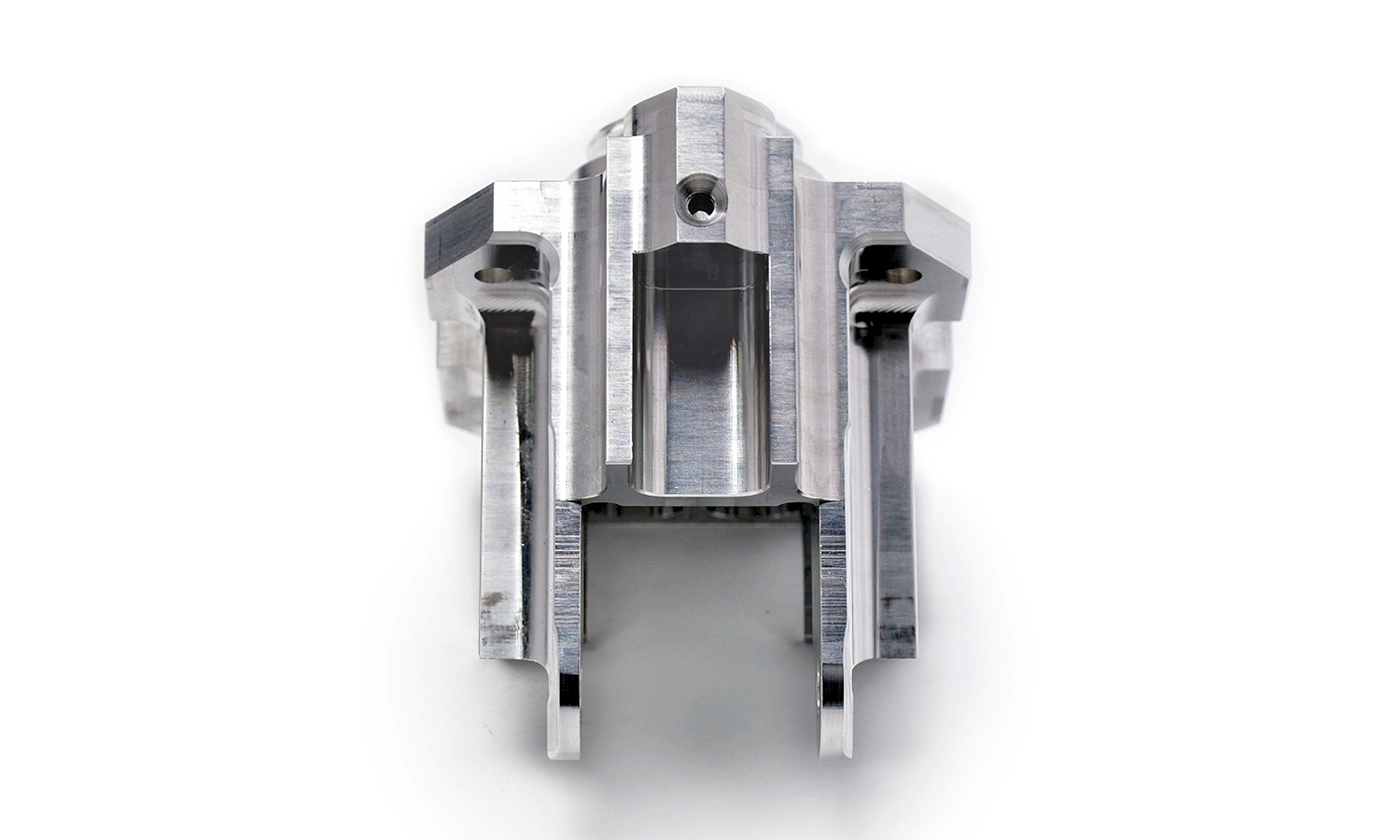

The part has a complex shape and a smooth surface. It is composed of several cylindrical and rectangular components that are machined in one-piece by using a CNC milling machine. The part has a silver-gray color and a metallic luster. It has holes, grooves, and slots that are designed to fit the ship engine components.

If you are interested in CNC-milled aluminum alloy ship engine spare parts, you can contact FacFox, a leading online platform for custom manufacturing services. FacFox can provide you with CNC milling services for any design and specification. You can upload your 3D model, choose your material and finish, and get an instant quote on facfox.com.

Solution

- Step 1: A 3D model of the part was created using a computer-aided design (CAD) software. The model contained all the details and specifications of the part, such as the shape, size, and features.

- Step 2: The 3D model was converted into a set of instructions for the CNC milling machine, using a computer-aided manufacturing (CAM) software. The instructions, also known as G-code, told the machine how to move and control the cutting tools to create the part.

- Step 3: A block of aluminum alloy 5052 was selected as the raw material for the part. Aluminum alloy 5052 is a metal that has good weldability and formability, as well as high strength and corrosion resistance. The block was clamped and secured on the worktable of the CNC milling machine.

- Step 4: The CNC milling machine was started and followed the G-code instructions to cut and shape the block of aluminum alloy into the desired part. The machine used various cutting tools, such as drills, end mills, and taps, to create holes, grooves, and slots on the part. The machine also used coolant and lubricant to reduce friction and heat during the milling process.

- Step 5: The CNC milled aluminum alloy ship engine spare part was finished and removed from the worktable. The part was inspected and measured to ensure that it met the quality standards and specifications. The part was then cleaned and polished to achieve a smooth surface finish.