- SLA 3D Printed White Resin Awkward Orange Garage Kit

- Brass Writing Award Trophy Miniature Cast from 3D Printed Wax Pattern

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 20 workdays

Gallery

About Project

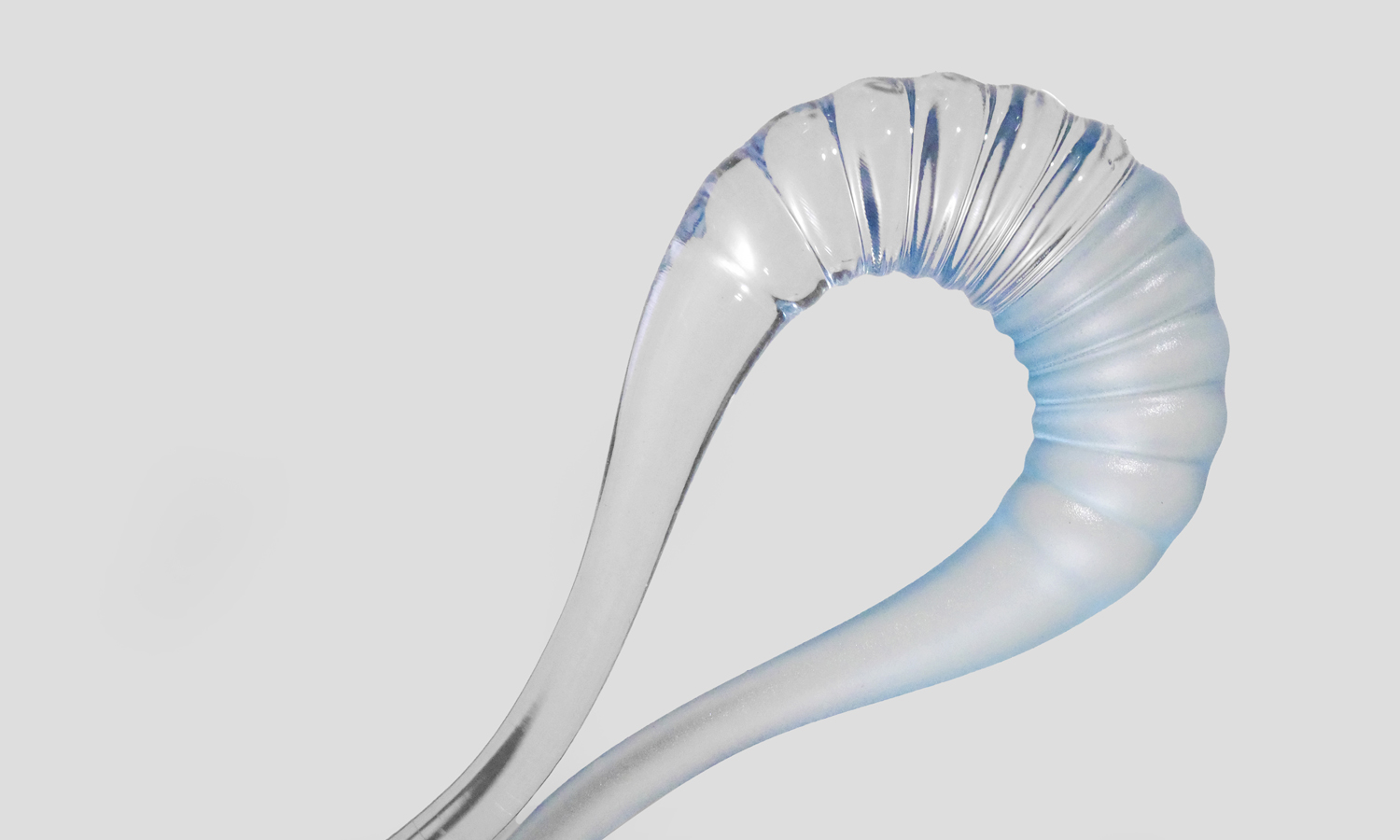

If you are a fan of our SLA 3D Printed Clear Resin Artist Wavy Handbag, you will love this new version that we have created with a different post-processing technique. This is the SLA 3D Printed Clear Resin Artist Handbag Frosted Baby Blue, and it is a stunning piece of art that combines transparency and opacity in a beautiful way.

This handbag uses the same 3D model as the clear resin wavy handbag, which was designed by a talented artist on Instagram. The design features a wavy structure on the bottom half of the bag, which is reminiscent of ripples on water. The waves add a sense of texture and interest to the bag, as well as creating a contrast with the smooth and sleek upper half. The handles are thin and elegant, but also strong and durable.

The handbag was 3D printed in one piece with SLA Clear Resin, a material that is as clear as glass and has excellent mechanical properties. However, instead of polishing the whole handbag to make it transparent, we decided to give it a different look by using two post-processing techniques: dyeing and bead-blasting.

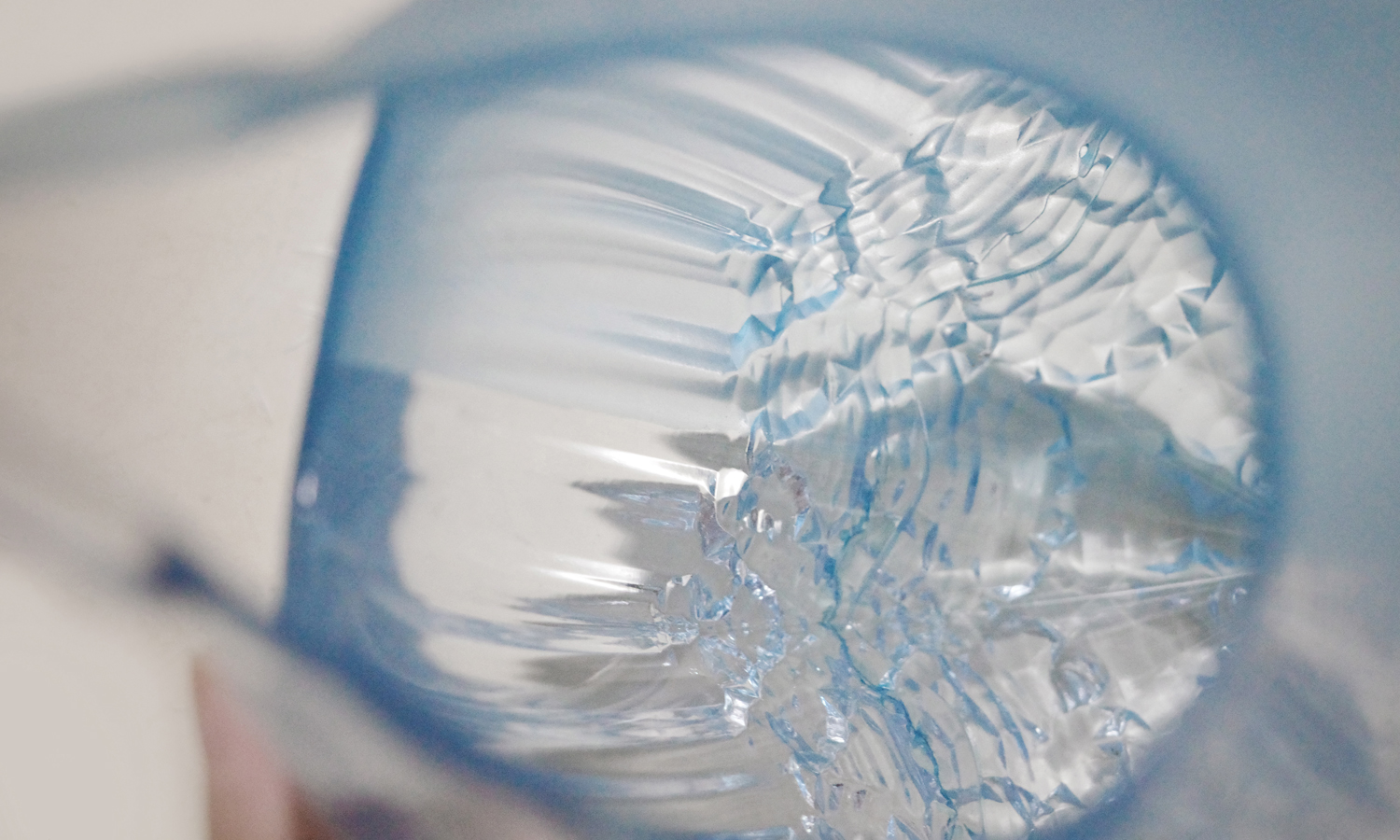

First, we rinsed the 3D-printed handbag in a light blue dye solution for minutes after post-curing. This gave the handbag a subtle baby blue color that enhanced its aesthetic appeal. Then, we fine-polished the handbag, top-to-bottom, inside-to-outside, to make it as transparent as possible. The handbag looked like a crystal blue gem at this stage.

Next, we protected the left half of the handbag with masking tape, and sandblasted the right half with fine glass beads. This created a matte frosted surface on the right half of the handbag, which contrasted with the glossy transparent surface on the left half. The frosted surface also diffused the light and created a soft glow effect. The handbag looked like a frozen ice sculpture at this stage.

The result was a stunning SLA 3D Printed Clear Resin Artist Handbag Frosted Baby Blue, that showcased the beauty and versatility of 3D printing and post-processing. This handbag is a perfect example of how 3D printing can create amazing artworks that combine aesthetics and functionality. If you are interested in this handbag, or want to customize your own 3D printed clear resin artwork, please visit our website at facfox.com, where you can find more information and place your order. We are looking forward to hearing from you!

This handbag is a custom-made artwork for a talented artist on Instagram, who entrusted us with their creative vision. We respect their originality and exclusivity, and we will not sell or share the 3D model or the prints of this handbag with anyone else.

Solution

- Step 1: The 3D model of the handbag was designed by the artist on computer software, and then exported as a STL file.

- Step 2: The STL file was imported into a slicing software, where the printing parameters, such as layer height, orientation, and supports, were set. The slicing software generated a G-code file that instructed the 3D printer how to print the handbag.

- Step 3: The G-code file was transferred to the 3D printer, which used SLA (stereolithography) technology to print the handbag. SLA is a process that uses a laser to cure liquid resin into solid layers. The 3D printer had a resin tank filled with SLA Clear Resin, and a build platform that moved up and down. The laser scanned the cross-section of the handbag on the surface of the resin, and cured it into a solid layer. Then, the build platform moved up slightly, and the laser scanned the next layer. This process was repeated until the whole handbag was printed.

- Step 4: The printed handbag was removed from the build platform, and then washed with isopropyl alcohol to remove any excess resin. The handbag was still soft and sticky at this stage, so it had to be handled carefully.

- Step 5: The handbag was placed in a UV curing chamber, where it was exposed to UV light for a certain amount of time. This process hardened and strengthened the handbag, and also improved its transparency.

- Step 6: The handbag was rinsed in a light blue dye solution for a few minutes after post-curing. This gave the handbag a subtle baby blue color that enhanced its aesthetic appeal.

- Step 7: The handbag was fine-polished with various grades of polishing compounds and cloths, starting from coarse to fine. This process removed any scratches or imperfections on the surface of the handbag, and made it as transparent as possible.

- Step 8: The left half of the handbag was protected with masking tape, and the right half was sandblasted with fine glass beads. This created a matte frosted surface on the right half of the handbag, which contrasted with the glossy transparent surface on the left half. The frosted surface also diffused the light and created a soft glow effect.

- Step 9: The masking tape was removed and the handbag was cleaned with water and soap, and then dried with a soft cloth. The handbag was inspected for any defects or flaws, and then packed with foam and bubble wrap in a sturdy box for shipping.