- SLA 3D Printed Clear Resin Artist Handbag Frosted Baby Blue

- SLA 3D Printed Clear Resin Cosmetic Container Prototype

Material Resin, Metal

Quantity 1 pcs

Price Range $100-1,000

Lead Time 10 workdays

Gallery

About Project

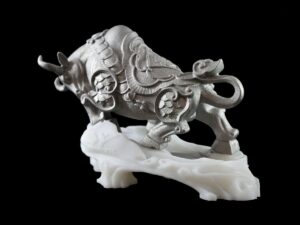

Are you looking for a unique and stunning trophy for your writing contest? Do you want to reward your participants and winners with a miniature masterpiece that reflects their talent? If so, you might want to check out the Brass Writing Award Trophy Miniature Cast from 3D Printed Wax Pattern, a product of FacFoxŌĆÖs 3D printing and metal casting services.

This trophy is a small object, smaller than your thumb, but it has an intricate hollowed geometric design that resembles a flower. The top of the trophy has a raised pen pattern, symbolizing the writerŌĆÖs expression, while the bottom has a sunken pen pattern, representing the writerŌĆÖs creativity. The trophy is made of brass, a metal that has a warm and elegant appearance, and it has been polished on the surface to enhance its shine.

How did FacFox create this amazing trophy?┬ĀThe process involved two steps: 3D printing and metal casting. First, FacFox used Wax Jetting, a 3D printing technique that is similar to the standard 2D ink-jetting process.┬ĀWax Jetting uses nozzles to deposit molten wax filament on an aluminum build platform, creating smooth and precise models. FacFox printed the wax pattern of the trophy using Wax Jetting, ensuring that every facet and pen was captured faithfully.

Next, FacFox used metal casting to transform the wax pattern into a brass trophy. Metal casting is a technique that involves pouring molten metal into a mold and letting it solidify into the desired shape. FacFox used the wax pattern as the mold, creating a hollow cavity inside it by melting out the wax. Then, they poured molten brass into the cavity, filling it with metal. After cooling down, they removed the excess metal and cleaned up the trophy.

The result is a stunning and unique trophy that celebrates the art of writing. The Brass Writing Award Trophy Miniature Cast from Wax Jetting 3D Printed Wax Pattern is a perfect example of how FacFox combines 3D printing and metal casting to create amazing products for various applications. Whether you need trophies, jewelry, sculptures, or any other custom metal items, FacFox can help you turn your ideas into reality. Contact them today via info@facfox.com and get started on your next project!

Solution

- Step 1: The 3D model of the trophy was designed using CAD software, and the STL file was sent to FacFox for a quotation. Required amount, material and finishing should be communicated at this stage.

- Step 2: The 3D model was converted into a wax pattern using Wax Jetting, a 3D printing technique that deposited molten Castable Wax on an aluminum build platform. The wax pattern was smooth and precise, and it captured every facet and pen of the design.

- Step 3: The wax pattern was attached to a sprue, a metal rod that connected the pattern to a funnel-shaped cup. The sprue and the cup formed the gating system, which allowed the molten metal to flow into the mold cavity.

- Step 4: The wax pattern and the gating system were coated with a ceramic slurry, a liquid mixture of fine sand and binder. The ceramic slurry formed a thin layer around the wax pattern and the gating system, creating a shell mold. The shell mold was dried and then repeated several times until it reached the desired thickness and strength.

- Step 5: The shell mold was placed in an oven and heated to a high temperature. The heat melted out the wax pattern and the gating system, leaving behind a hollow cavity inside the shell mold. This process was called lost-wax casting, as the wax pattern was lost in the process.

- Step 6: The shell mold was taken out of the oven and placed in a sand pit. Molten brass was poured into the cup, which flowed through the sprue and filled the cavity inside the shell mold. The brass solidified into the shape of the trophy.

- Step 7: The shell mold was broken and removed from the brass trophy. The excess metal and the sprue were cut off and recycled. The brass trophy was cleaned and inspected for any defects or flaws.

- Step 8: The surface of the brass trophy was polished to make it shine. The polishing process enhanced the appearance of the trophy, but it did not affect its fine details or design. The Brass Writing Award Trophy Miniature Cast from 3D Printed Wax Pattern was ready to be delivered to its recipient.