SLA 3D Printed and Vacuum Plated Giant Golden Skull Model

Posted on 2020-12-16 in Art ┬Ę Ķē║µ£»

Process 3D Print, Paint, Polish, Electroplate

Material Resin

Quantity 1 pcs

Price Range $1,000-5,000

Lead Time 20 workdays

Material Resin

Quantity 1 pcs

Price Range $1,000-5,000

Lead Time 20 workdays

Gallery

About Project

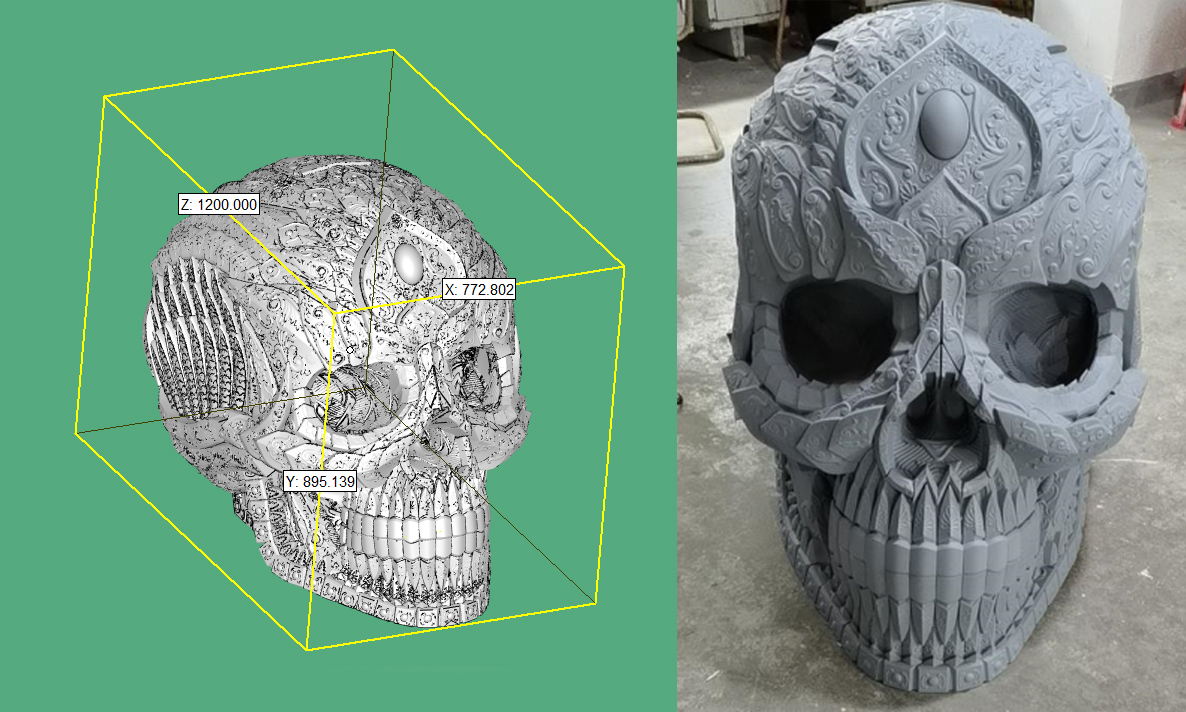

Skull art is found in various cultures of the world. The one-meter-high giant golden skull model which has gorgeous patterns and beautiful gloss, will catch all the eyes once placed in the room.

Challenge

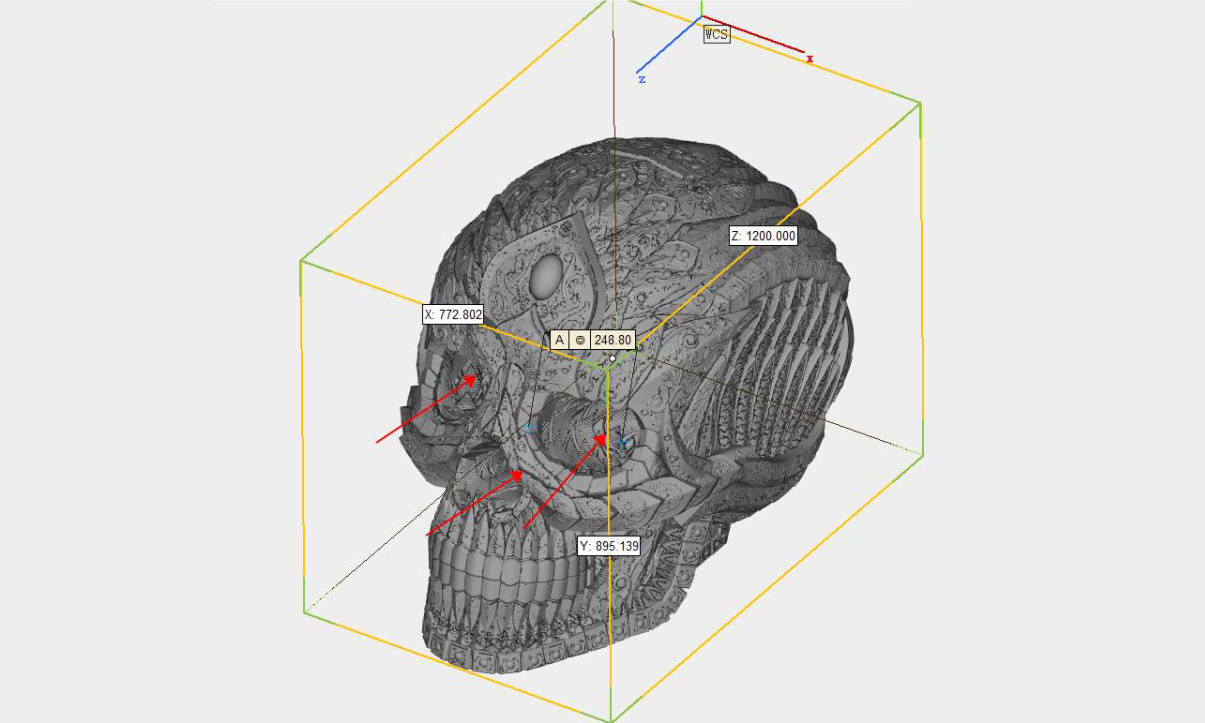

The hollow of the skull structure where the eyeballs and nose should be are too deep so that the coating of vacuum plating is thin and these parts will look relatively dim.

Solution

- Step 1: As the size of the skull is larger than the build volume of our industrial SLA 3D printers, our engineer needs to split the 3D model into four parts, following the pattern so that the division line won’t look obvious after assemble.

- Step 2: Considering the pattern of the skull model is very complicated and intricate, we first make a small scale model for testing. It can help us find out the possible failure during printing.

- Step 3: Manufacture the pieces with SLA 3D Printing technology. As the model is placed indoors as told by our client, we choose SLA Tough Resin, which has better stiffness and impact resistance than generic resin, and produces parts with improved mechanical properties.

- Step 4: Regular post-processing, including support removal, sanding, and polishing.

- Step 5: Assemble all the parts, add fiberglass inside the model, and bond with super glue.

- Step 6: Spray with grey putty, check the surface, and make some little adjustments.

- Step 7: Turn the surface into golden color with vacuum plating technology. The resin parts cannot be electroplated, but vacuum plating can realize the same effect. At last, we apply UV oil to make it shinier and UV-resistant.