- DLP 3D Printed and Investment Cast Brass Parrot Models

- SLA 3D Printed and Vacuum Plated Giant Golden Skull Model

Gallery

About Project

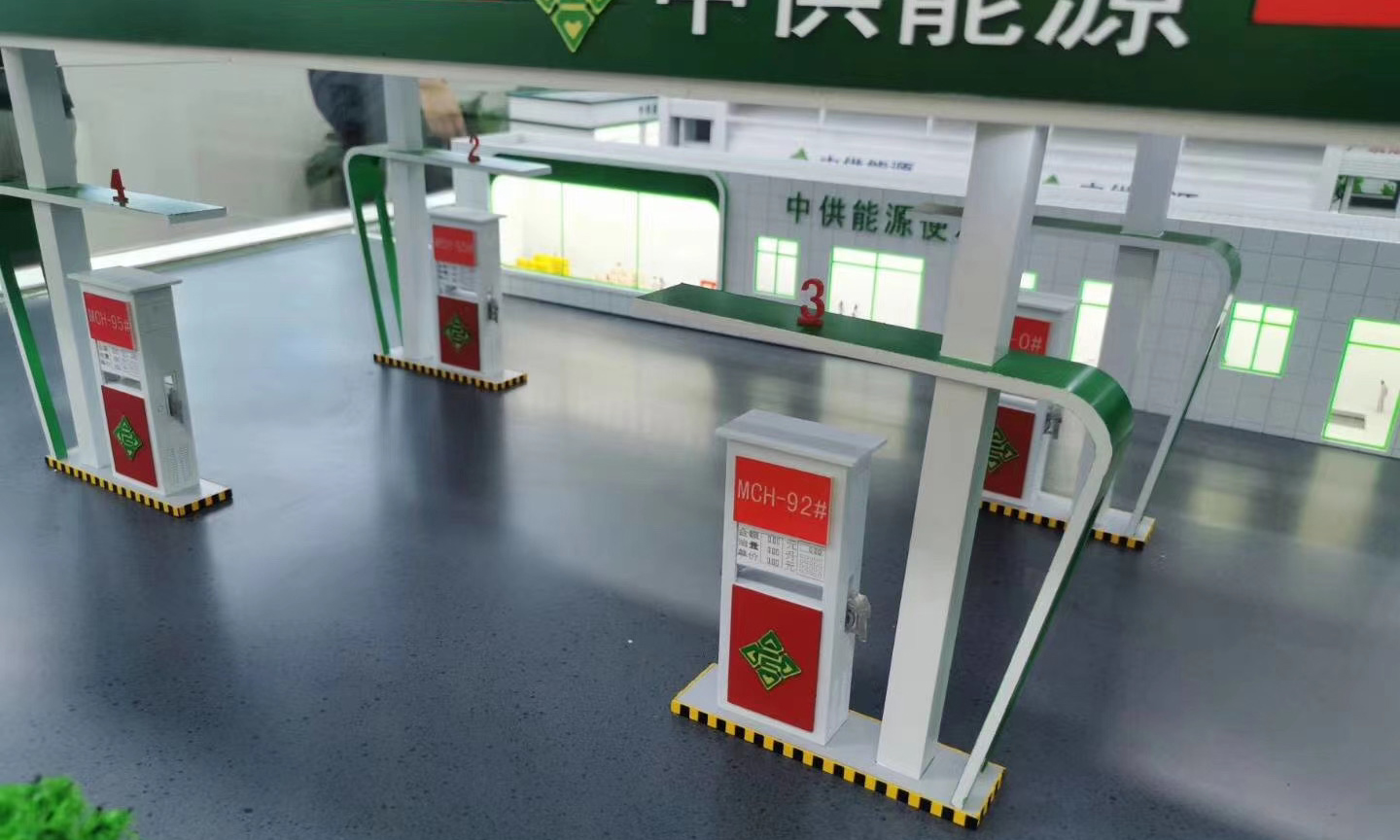

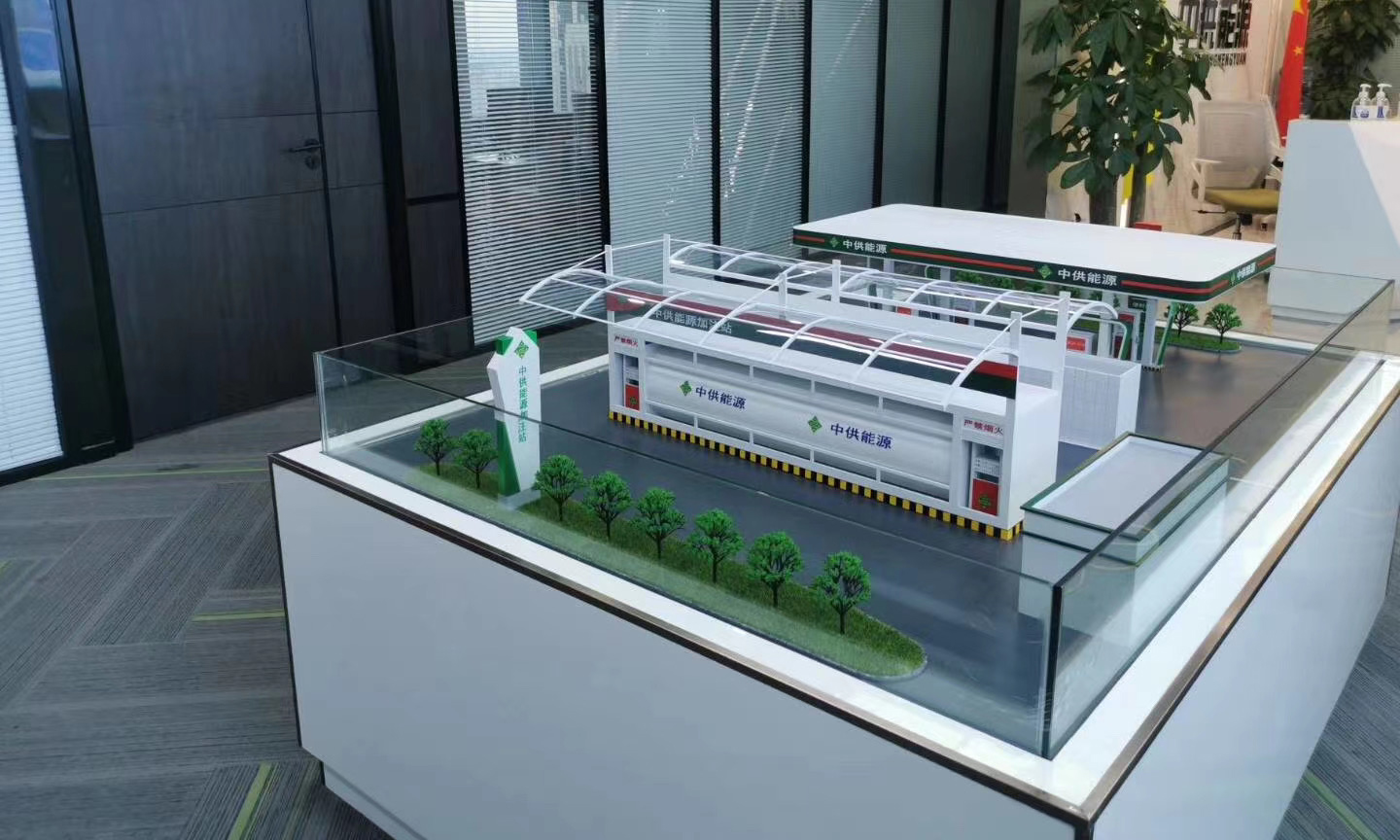

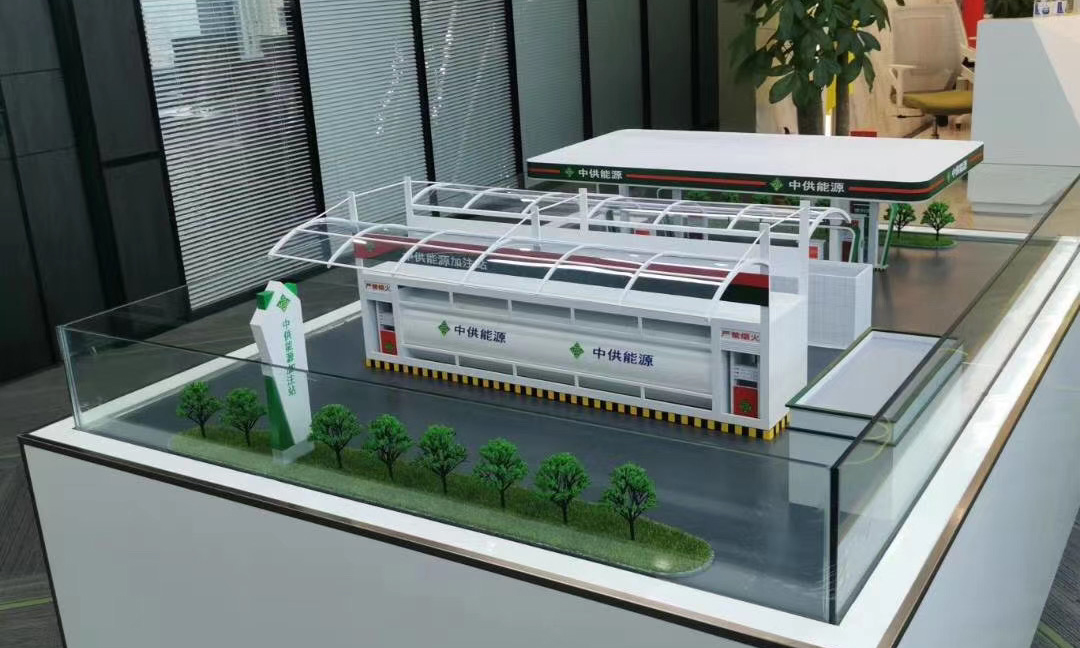

A filling station is a facility that sells fuel and engine lubricants for motor vehicles. Most filling stations are built in a similar manner, with most of the fuelling installation underground, pump machines in the forecourt, and a point of service inside a building.

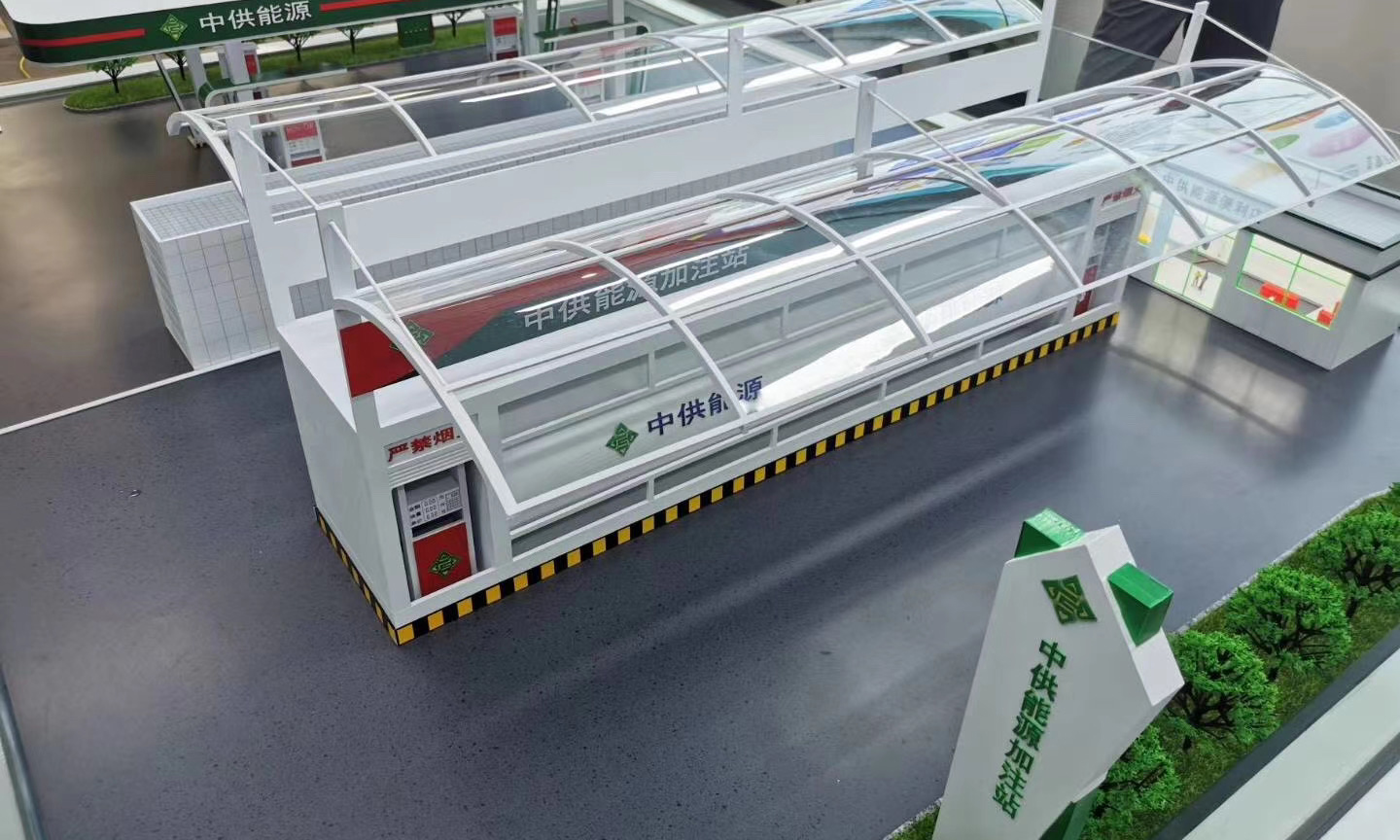

Single or multiple fuel tanks are usually deployed underground. Fuel is usually offloaded from a tanker truck into the tanks through a separate valve, located on the filling station's perimeter. Fuel from the tanks travels to the dispenser pumps through underground pipes. For every fuel tank, direct access must be available at all times. Most tanks can be accessed through a service canal directly from the forecourt.

An energy company ordered the filling station scale model from us. Most industrial companies have a showroom to place the models and real products which can represent their main business. The person in charge would show you around when visiting their plants and factories.

Solution

- Step 1: Our engineer split the models into two kinds: the white ones, printed with SLA Generic Resin; and the transparent roof of the rain sheds, printed with SLA Clear Resin. To improve the efficiency of the printing process, we arrange the placement in the slicing software according to the build volume of the SLA 3D printer.

- Step 2: We add supports for the hollowed parts and overhang structure to avoid printing failure. As all the models are placed on a board, we print the buildings upside down to avoid the use of supports, thus we can save material and decrease printing hours. Besides, two pieces of the rain sheds of the gas containers are connected with thin rods. To avoid the breakage of the rods, we communicate with our client the adjust the parameters of them.

- Step 3: Take out the prints from the chamber. Cut off the supports with a grater and remove the marks and bumps with filing paper. Assemble the window with the gas containers. Paint and screen print the models. Glue all the models onto the board.