Material Plastic

Quantity 1 pcs

Price Range $1-100

Lead Time 1 workdays

Gallery

About Project

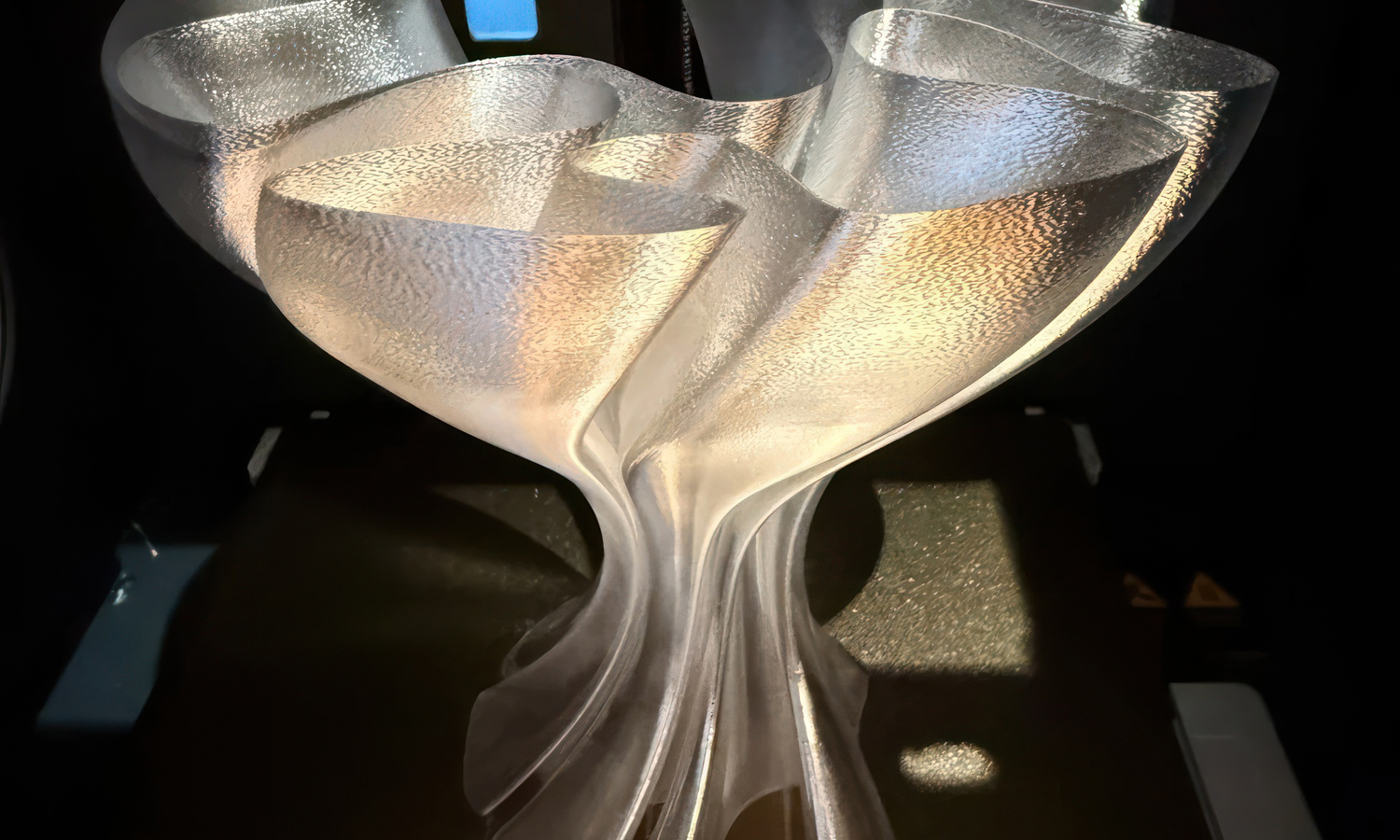

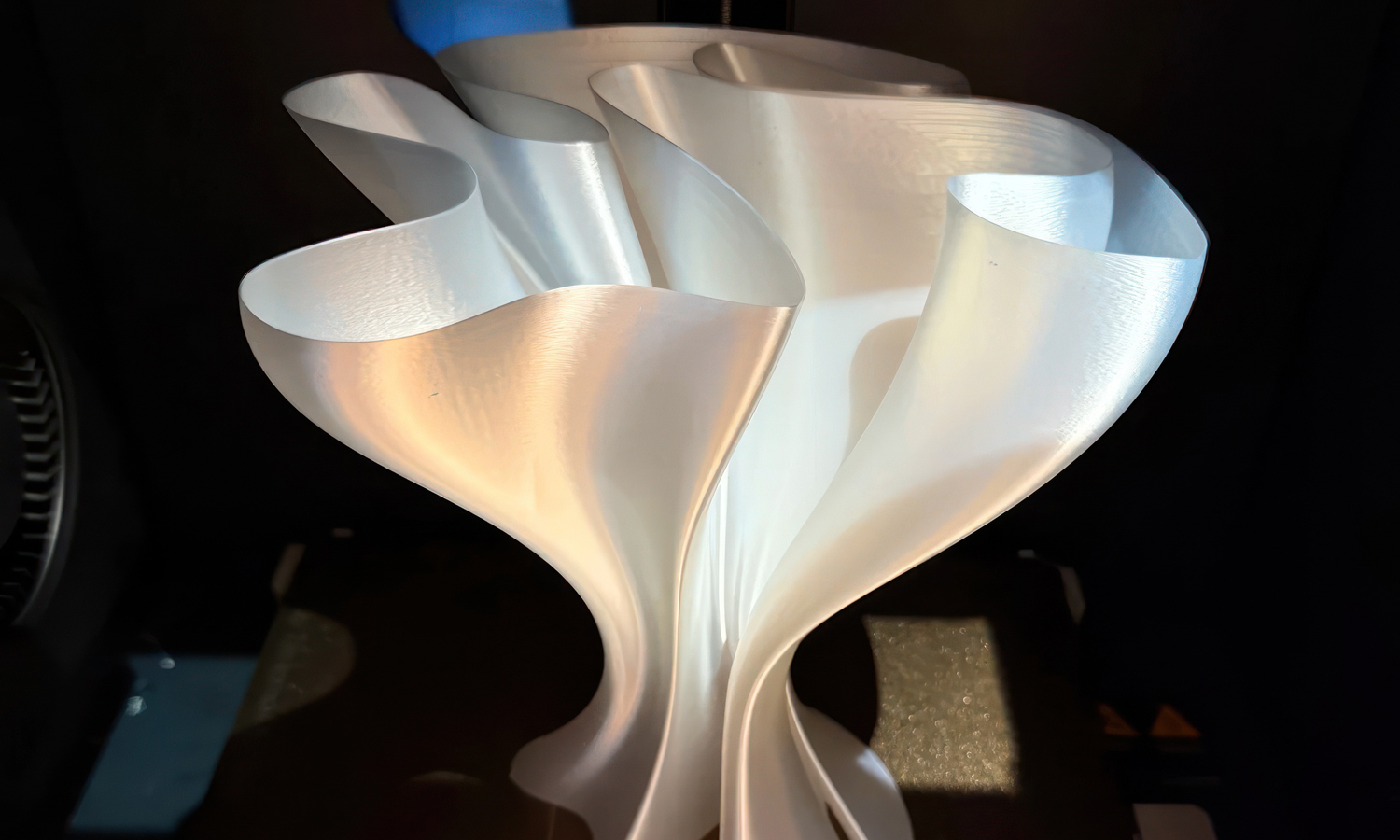

This mesmerizing vase captures the essence of a blooming bouquet-without needing a single flower. Elegantly twisting and curling like the petals of an opening blossom, the vase is 3D printed using silky, pearlescent PLA filament that shimmers with every movement of light. Its translucent white sheen enhances its sculptural form, giving it the look of frozen motion-a delicate swirl suspended in time.

Designed for aesthetic impact, this piece bridges the gap between function and art. Whether displayed on its own or used to hold dry arrangements, it makes a sophisticated statement in any space. The precision of FDM 3D printing is on full display here, with clean curves, layered textures, and a fluid form that would be nearly impossible to replicate by hand.

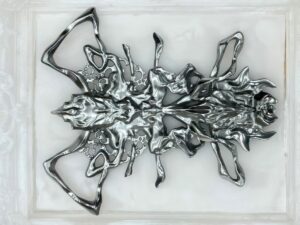

Although this specific vase wasn’t printed by us, at FacFox, we offer professional FDM 3D printing services using premium Silk PLA filament in a wide range of colors. Our silk PLA delivers stunning glossy finishes, ideal for vases, art pieces, cosplay props, and decorative prototypes. If you’re inspired by this design or want to bring your own creation to life, we’re here to help you realize it with the highest print quality and expert support.

Start your custom silk PLA 3D printing project with FacFox today!

Solution

- Step 1: The 3D model of the bouquet-style vase was designed using parametric CAD software to create flowing, petal-like curves and an elegant organic form.

- Step 2: The digital model was sliced using a specialized slicing software, with settings optimized for Silk PLA, including low layer height for smooth surfaces and moderate printing speed to prevent stringing.

- Step 3: A spool of white Silk PLA filament was loaded into an FDM 3D printer. The print bed was leveled and heated to ensure proper first-layer adhesion.

- Step 4: The printing process was initiated. The vase was printed in a single continuous motion using the spiral vase mode (also known as vase mode), minimizing layer seams and creating a seamless structure.

- Step 5: Throughout the print, consistent extrusion and cooling were maintained to preserve the model’s delicate curves and achieve a glossy, reflective finish.

- Step 6: Once the print was completed, the vase was carefully removed from the build plate and inspected for any imperfections or artifacts.

- Step 7: Minor stringing and edges were trimmed or lightly sanded by hand, and the vase was then ready for use or display without requiring post-processing like painting or coating.