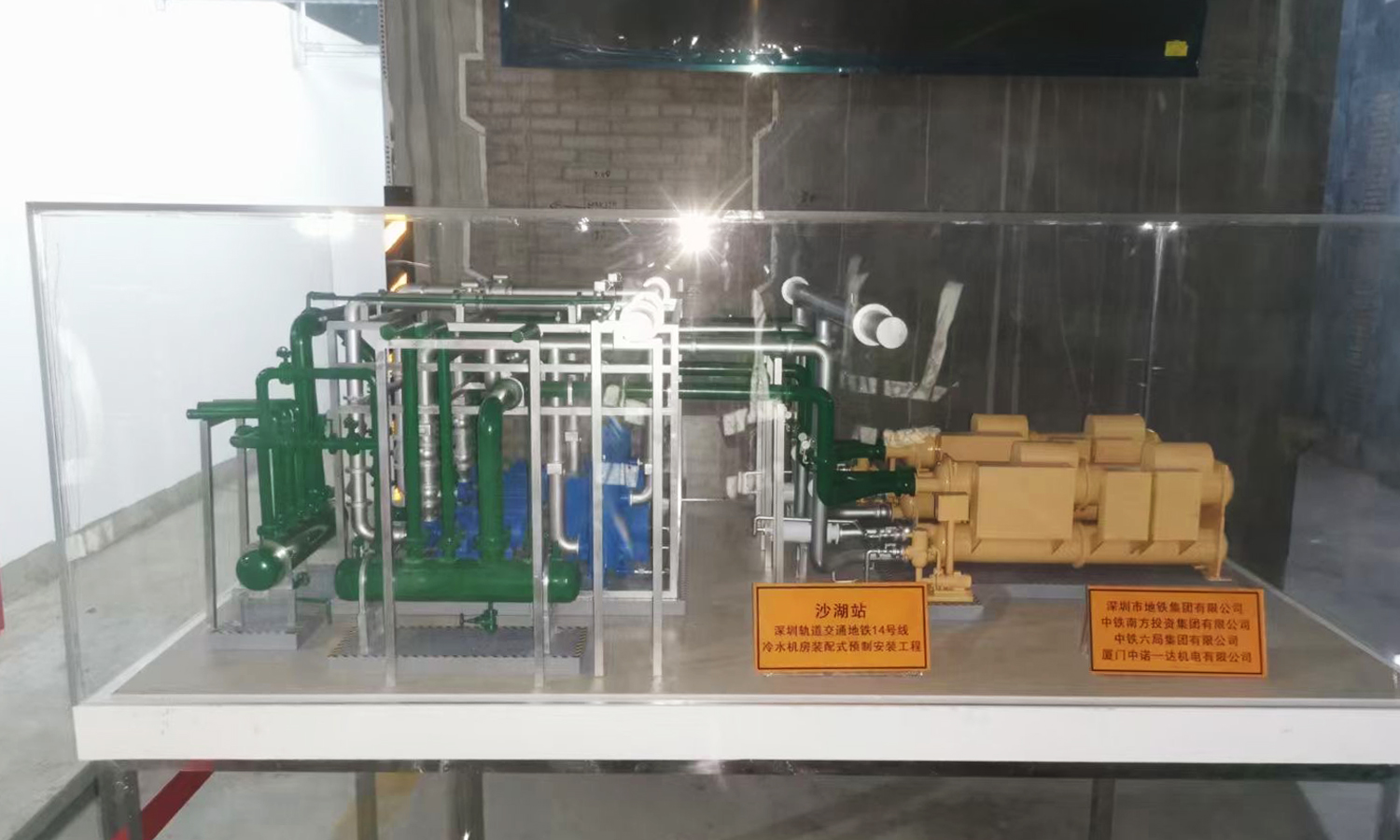

SLA 3D Printed Resin Chilled Water Pipeline Model for a Subway Station

- SLA 3D Printed Cosplay Helmet Garage Kit Display Model

- SLA 3D Printed 4.5m Long Food Production Line 1:15 Resin Model

Posted on 2021-08-13 in Architecture آ· ه»؛ç‘

Process 3D Print, Support Removal, Post Curing, Polish, Paint

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 9 workdays

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 9 workdays

Gallery

About Project

The pipeline model indeed is one of the most challenging models to be printed. Not only there are many supports that need to be removed with care, but the model scaling is also complicated. The supports determine the printing cost is not as low as the client thought, and when they want to scale down the model, the wall thickness of the pipeline became less than 1mm, which meant it would break easily. It would take a long time to adjust the model.

Solution

- Step 1: For 3D models like tube systems and vehicle skeletons, we need to calculate the price including the printing cost of support structures. The client then scales down the model but the wall thickness becomes less than 1mm, which is easily broken during printing and support removal.

- Step 2: The client takes our advice and thickens the wall thickness of all the tubes and changes them from hollow to solid. Split them into different units for simpler post-process. Add supports and arrange the placement on slicing software.

- Step 3: 3D print the models with SLA Generic Resin using our industrial 3D printer. The layer thickness we set is 0.05mm.

- Step 4: Rinse the model with IPA and post-cure with UV. Cut off all the supports, then polish with sandpaper.

- Step 5: Spray all the parts with silver blue and green paint. Glue the whole model into one piece and pack it with a wooden box.